-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

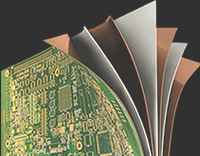

Advanced PCBs are commonly used in high-precision electronic devices. With the continuous development of technology, the demand is also getting higher and higher. To this end, the separate advanced PCB production workshop is opened to assist our customers achieve the best possible time to market and competitive advantage by producing PCBs in a sustainable way at the lowest total price through APOLLOPCB fabrication capabilities, delivery punctuality and product quality. Check Advanced PCB manufacturingCapability

• Normal FR-4 Board

• Aluminum Board

• Rogers

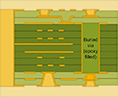

• HDI(Buried/blind vias)

• Copper Base

• HASL with lead \ lead free

• Immersion gold(ENIG)

• OSP

• Hard Gold

• Immersion silver(Ag)

• Half-cut/Castellated Holes

• Impedance control

• Buried/blind vias

• Via filled with resin

• Countersinks/Counterbores

• Z-axis milling

Children's toys, small appliances, home lighting, functional testing, electronic enthusiasts, etc. Suitable for users whose prices are core competitiveness

| Senior engineer (one file/6 hours) | Engineering | mid-level engineer (5 files/hours) |

| individual working panel | Production | mixed working panel |

| ≥1 piece | Quantity | 5,10,15,20,25...pieces |

| Shengyi,Rogers,Arlon,Isola,Omega,Nelco,3M etc. Meet IPC4101 class B/L | Material | KB(kingboard)/GDM(goldenmax) Meet IPC4101 class B/L |

| Rohm&Haas,TAIYO,Kuangshun,Meet IPC-SM-840 class | Ink,Soldermasks | TAIYO,Kuangshun,Meet IPC-SM-840 class T |

| Min Mechanical Hole Size 0.15mm,Laser hole 0.1mm | Drilling | Min Mechanical Hole Size 0.2mm |

| PTH (Hole copper thickness≥20um),IPC 3(25um) | Plating | PTH(Hole copper thickness≥18um) |

| ±2mil | Soldermask offset | ±3mil |

| ±0.13mm | Dimensional deviation | ±0.2mm |

| 0.75% | Warping angle | 1% |

| A.O.I,Kelvin Four-terminal sensing,Microsection Inspection,Solderability Test,Impedance Test... | Test method | A.O.I.,Fly Probe Testing |

| >140℃ | Glass transition ℃ | >130℃ |

| Humidity indicator cards | Package | None |

| Inspection report | Inspection report | None |

| IPC Class 2,IPC Class 3,Automotive Standard, Customer Standard | Standard | IPC Class 2 |

| Forbid to repair tracks(IPC 3,Automotive, Customer Standard) | Etched line | - |

| Cleanliness requirements beyond those of IPC | Cleanliness | Meet IPC standards |

| UL,ISO9001:2008,ISO14001:2004,ISO/TS16949:2009, RoHS etc. | Certification | UL,ISO9001:2015,RoHS etc. |

APOLLOPCB Automated Production Lines and Professional Technicians

Material:FR-4 TG150

Application Area:Industrial control

Layers/Thickness:6/1.6mm

Surface Finish:Immersion gold

Min Track/Spacing:3/3mil

Min Hole Size:0.15mm

Material:Rogers - Rogers4003C

Application Area:Industrial control

Layers/Thickness:4/1.6mm

Surface Finish:Immersion gold

Min Track/Spacing:3/3mil

Min Hole Size:0.15mm

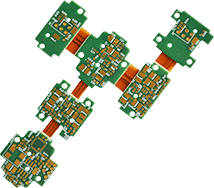

Material:FR4+FCCL

Application Area:Electronic Industry PCBs

Layers/Thickness:4L/0.8mm

Surface Finish:OSP

Min Track/Spacing:4/4mil

Min Hole Size:0.20mm

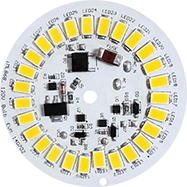

Material:Aluminum Board(Conductivity: 5.0W)

Application Area:Electronic Industry PCBs

Layers/Thickness:1L/1.0mm

Surface Finish:HASL lead free

Min Track/Spacing:6/6mil

Min Hole Size:1.0mm

APPLICATION INDUSTRIES

APPLICATION INDUSTRIES

NETWORK & COMPUTER

NETWORK & COMPUTER

CONSUMER ELECTRONICS

CONSUMER ELECTRONICS

TELECOMMUNICATIONS

TELECOMMUNICATIONS

AEROSPACE

AEROSPACE

AUTOMOTIVE ELECTRONICS

AUTOMOTIVE ELECTRONICS

NEW ENERGY

NEW ENERGY

BIOMEDICAL

BIOMEDICAL

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB