-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

Real PCB &PCB Assembly Manufacturer

IS09001:2015 Standard

UL.RoHS. REACH Certified

3000+ Orders/Day

99% on-time Shipping

100,000+ Customers

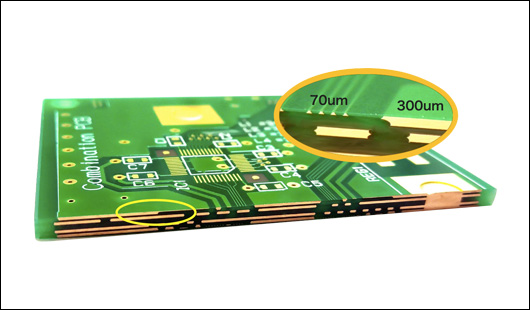

Usually, the copper thickness of a standard PCB is 1oz to 3oz. Thick-copper PCBs or heavy-copper PCBs are the types of PCBs that the finished copper weight is more than 4oz (140μm).

What are the uses of thick-copper PCBs?

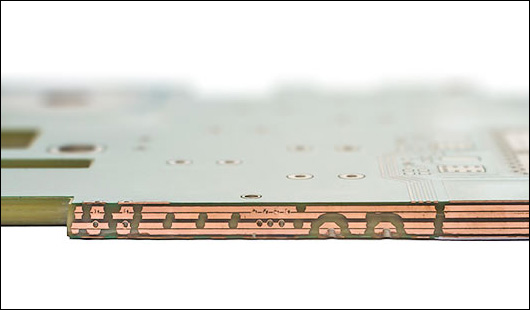

Thick-copper PCBs are widely used in power supply systems and power electronic equipment. Additional copper weight in PCBs allows higher currents to be conducted from the board and helps to dissipate heat. The most common thick-copper PCBs are double-sided or multi-layered.

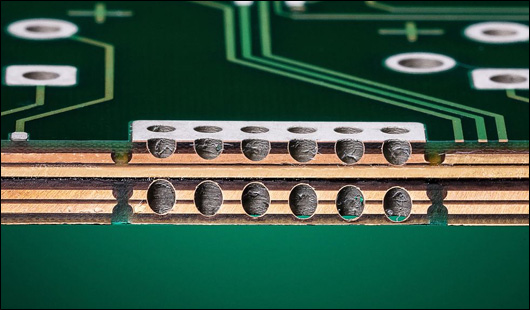

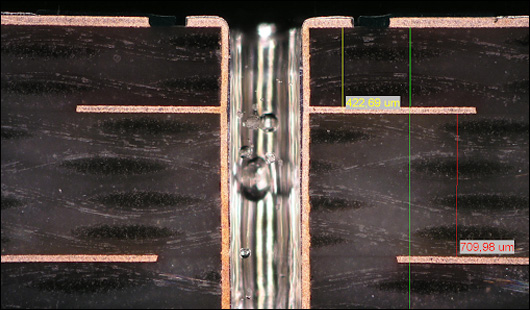

The thick-copper PCB belongs to a special type of PCB. its conductive materials, substrate materials, production process, application fields are different from the conventional PCBs. The plating of thick copper circuits allows PCB manufacturers to increase the copper weight in via sidewalls and plated holes, which can reduce the layer numbers and footprints. Thick-copper plating integrates high-current and control circuits, making high-density with simple board structures can be achieved.

The construction of heavy-copper circuits gives the PCBs the following advantages:

1. Increase current capacity greatly

2. Higher endurance to thermal strains

3. Better heat dissipation

4. Increase the mechanical strength at connectors and PTH holes

5. Reduce the product size

undefined

The applications of thick-copper PCBs

Along with the increasing of high-power products, the demand for thick-copper PCBs is greatly increased. Today’s PCB manufacturers pay more attention to using a thick copper board to solve the thermal efficiency of high-power electronics.

The thick-copper PCBs are mostly large current substrate, and large current PCBs are mainly used in power module and automotive electronic parts. Traditional automotive, power supply, and power electronics applications use the original forms of transmission like cable distribution and metal sheet. Now the thick-copper boards replace the transmission form, which not only can improve productivity and reduce the time cost of wiring, but also increase the reliability of final products. At the same time, the massive current boards can improve the design freedom of wiring, thus realizing the miniaturization of the whole product.

In short, thick-copper circuit PCB play an irreplaceable role in the applications with high-power, high current, and high cooling demand. The manufacturing process and materials of heavy-copper PCBS have much higher requirements than standard PCBs. With advanced equipment and professional engineers, APOLLOPCB provides thick-copper PCBs with high-quality for customers from home and abroad.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB