-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

Real PCB &PCB Assembly Manufacturer

IS09001:2015 Standard

UL.RoHS. REACH Certified

3000+ Orders/Day

99% on-time Shipping

100,000+ Customers

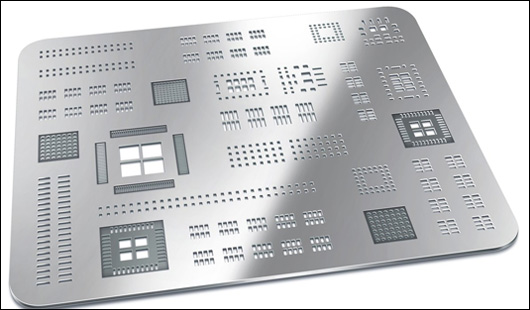

What is the laser stencil?

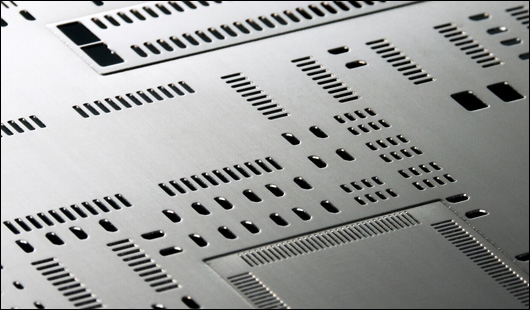

Laser stencil is a type of stencil used for assembling components in PCB manufacturing. There are three stencil types according to different processes: laser cutting, chemical etching, and electroforming. Laser Stencil is usually a thin sheet made of stainless steel, and it is more precise than the other two stencil types.

You can choose a framework or non-framework stencils when placing an order. Framework stencils are used for automated and semi-automated stencil machines, and there are several standard sizes to be chosen. Non-framework stencils are typically used for hand solder, and you can customize the stencil sizes according to your requirements.

undefined

The function of laser stencil

As the unique tool for surface mount devices (SMD), a laser stencil helps to apply the solder paste to exact positions. A laser machine cut the stencil into a circuit pattern that matches the locations where the components are installed. After fixing the stencil on the PCB, the solder paste will be applied on the board through the apertures of the stencil and form the pads. Then the components are mounted on the PCB through the processes of pick & place and reflow.

Usually, each stencil is only used for one circuit design. So, the quotation you get from PCB manufacturers always includes the stencil cost. But Sometimes the stencil is free of charge.

undefined

Why does APOLLOPCB provide laser stencil for customers?

When you place a PCB order on the website of APOLLOPCB, you will notice that there always a selection of SMD-Stencil that can be ordered together with PCB. There are some sizes that are available for framework stencils. The largest size of the stencil that APOLLOPCB can provide is 500mm*1400mm; its valid area is 320mm*1200mm.

The accuracy of the stencil has a crucial impact on the quality of the PCB assembly. APOLLOPCB recommends using laser stencil in PCB assembly prototype or PCB mass production because of its high precise and high production efficiency. Laser stencils are easier to operate and can reduce production time. You also can choose electro polishing or non-electro polishing when ordering the stencil. The electro polishing stencil offers a better result in PCB assembly.

With the fast development of electronics, the PCBs and components become more and more compact and high density. This trend leads to a high standard for the manufacturing processes and the assistive tools during production. High-quality laser stencil plays a vital role in improving the production efficiency and the quality of PCB assembly. APOLLOPCB provides one-stop services of PCB prototype, component sourcing, PCB assembly, and PCB testing for you. We will be your right choice if you are looking for a PCB manufacturer.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB