-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

Real PCB &PCB Assembly Manufacturer

IS09001:2015 Standard

UL.RoHS. REACH Certified

3000+ Orders/Day

99% on-time Shipping

100,000+ Customers

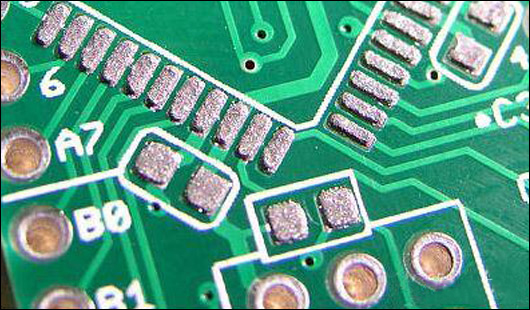

The silkscreen is usually the white images or texts we often see on the PCBs. The ink silkscreen uses a non-conductive epoxy ink. The standard colors we typically see are white, black, and yellow. But any other colors are also available. A well-designed silkscreen can reduce the chance of errors during PCB fabrication and the time to find these errors.

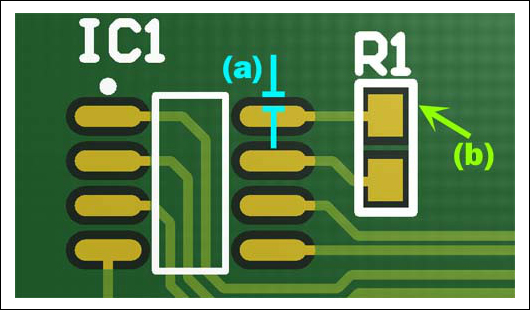

Silkscreen contains much information about the PCB assembly and PCB manufacturing, which are critical to the proper placement and orientation of the components. Therefore, silkscreen printing must be readable and clear to ensure effectiveness and practicality. Silkscreen usually provides the following information:

l Identifiers, component labels, logos.

l Identify the type of components.

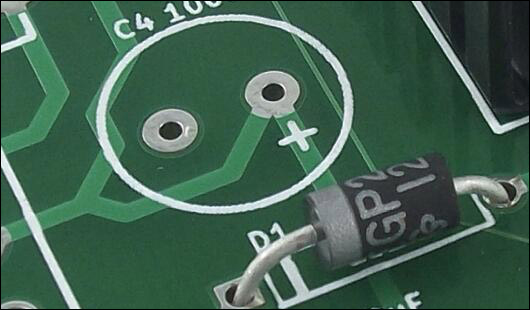

l Indicate the orientation of the polarized components.

l Indicate which pin should be connected to which pad.

l Warning symbols: some parameters should be avoided.

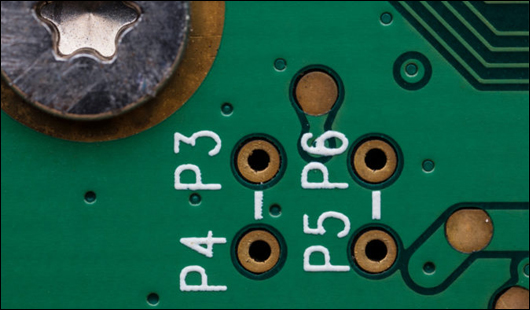

l Part numbers, test points,

l Labeling: manufacturer information, model, serial numbers, testing certifications, dates.

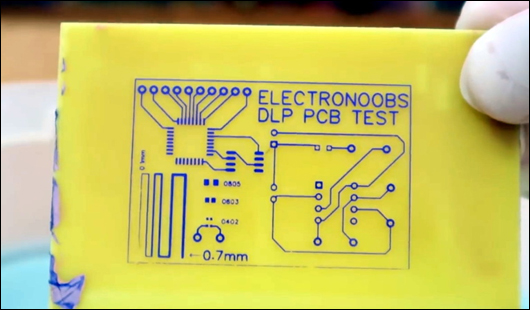

1. Direct legend printing (DLP)

This silkscreen method uses an individual inkjet printer with acrylic ink. The acrylic ink will be cured with UV light after printing. And DLP is considered the most accurate and fastest way to print PCB silkscreen. But it is the most expensive method.

2. Liquid photo imaging (LPI)

LPI is a process that is applying the liquid photo-imageable epoxy onto the board and exposing the board with UV light, and then the ink is cured. This method provides the best resolution of text and images but takes more time. It is a cost-effective silkscreen method.

3. Manual printing

Manual printing uses a text stencil that is made of nylon. After the epoxy ink is applied over the board by a stencil, then bake the board, and the ink will be cured. This method is faster and easier to manufacture than LPI, but it provides inaccurate results.

Nowadays, high-density PCB designs need smaller text sizes and better readability. DLP can meet these demands, and it becomes the best choice for silkscreen. If you have enough budget, choose DLP. If you need a cost-effective solution, choose LPI. If you don’t have a high standard for the silkscreen, manual printing is also available.

Now we have a better understanding of the importance of silkscreen printing for PCB assembly. Silkscreen may not be the most important step in PCB manufacturing, but it does have a useful role in helping manufacturers and engineers identify and locate the components easily. APOLLOPCB provides customers with a high-quality silkscreen process. If you have any problems with the PCB assembly prototype or other manufacturing processes, contact us!

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB