-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

Real PCB &PCB Assembly Manufacturer

IS09001:2015 Standard

UL.RoHS. REACH Certified

3000+ Orders/Day

99% on-time Shipping

100,000+ Customers

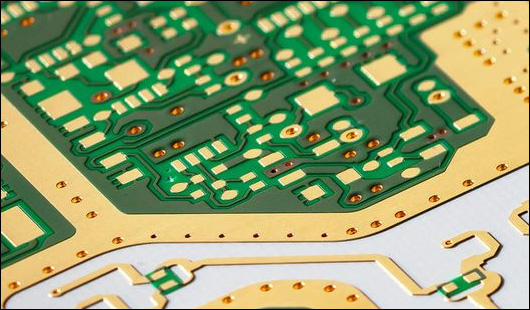

High-frequency PCBs usually provide a frequency range from 500MHz to 2 GHz, which can meet the needs of high-speed PCB designs, microwave, radiofrequency, and mobile applications. When the frequency is above 1 GHz, we can define it as high frequency.

The complexity of electronic components and switches is continually increasing nowadays and need faster signal flow rates. So, higher transmission frequencies are required. High-frequency PCBs help a lot when integrating special signal requirements into electronic components and products with advantages like high efficiency, and fast speed, lower attenuation, and constant dielectric properties.

Some considerations of high-frequency PCBs designs

High-frequency PCBs are mainly used in radio and high-speed digital applications, such as 5G wireless communications, automotive radar sensors, aerospace, satellites, etc. But there are many important factors to be considered when manufacturing high-frequency PCBs.

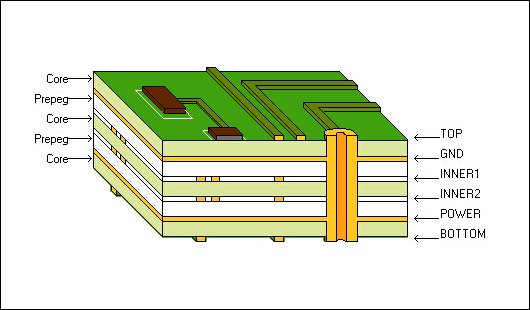

· Multi-layered design

We usually use multi-layered PCBs in high-frequency PCB designs. Multi-layered PCBs have assembly density and small volume, making them very suitable for impact packages. And multi-layered boards are convenient to shorten the connections between electronic components and improve the speed of signal transmission.

Ground plane designing is an important part of high-frequency applications because it not only maintains signal quality but also helps reduce EMI radiations.

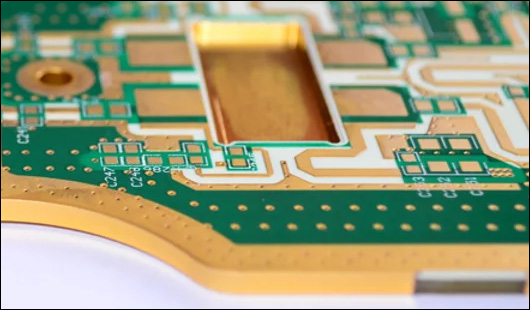

· The selection of materials

First, the substrate with low water absorption is more suitable in high-frequency PCB manufacturing because this can reduce the effect on dielectric constant (DK) and dielectric loss (Df). Second, the DK and the Df of the substrate must be small and stable, which helps to improve the quality of signal transmission. Third, the substrates and copper foils must have the same thermal expansion coefficient; otherwise, they will result in copper foil separation. Last, high-frequency PCB materials also need to be high heat resistant, chemical resistance, and strong peel-off resistance.

The performance of the high-frequency PCBs depends on the material used for construction. FR-4, Rogers, and Teflon are the most popular materials in high-frequency PCB designs.

undefined

All in all, because of the performance benefits, high-frequency PCBs have been widely used in high-speed and high-density PCB designs. Anyway, you also should consider that high-frequency materials are expensive than ordinary materials. It would be best to consider the actual needs of your PCBs and make a wise decision.

The demand for high-frequency and high-speed PCB products rises rapidly nowadays. As an experienced PCB manufacturer, APOLLOPCB is focusing on providing customers with reliable high-frequency PCB prototyping with high quality. If you have any problems with PCB designing or PCB manufacturing, please feel free to contact us.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB