-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

Real PCB &PCB Assembly Manufacturer

IS09001:2015 Standard

UL.RoHS. REACH Certified

3000+ Orders/Day

99% on-time Shipping

100,000+ Customers

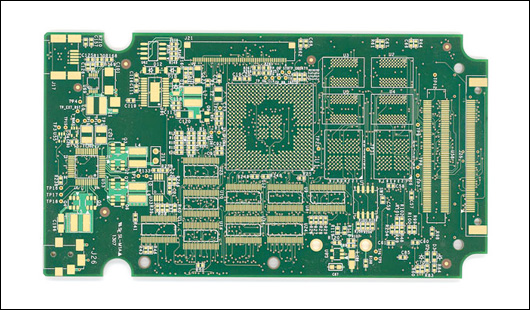

The definition of High-TG PCBs

High-TG PCBs are the boards with high glass transition temperatures. “TG” is the temperature point that the material begins to convert from solid to a rubbery state. The physical shape change is sure to have adverse effects on their functions and performance. If your PCBs operate at high temperatures for a long time, you would be better to choose high-TG materials.

High-TG PCBs indicate that their TG values are typically higher than 170 °C. Standard PCBs usually fabricated using the material with a TG value of 140 °C and can withstand a working temperature of 110 °C. but standard PCBs may not apply to extreme temperature environments that are common in industrial, automotive, and other high-temperature electronics applications. When it comes to these situations, FR4 material would be the best solution.

The thermal resistance of FR4 material is much higher than that of standard PCBs. When selecting a PCB, the TG value should be at least 20-25 °C higher than the expected operating temperature of the PCB. For example, if the TG value of the PCB is 170 °C, then the working temperature of the device should be lower than 150 °C.

undefined

The importance of high-TG PCBs

High-TG PCBs perform better at high temperatures and have better stability, making them reasonable solutions for high power density designs. The higher the TG of the board is, the higher the heat resistance, chemical resistance, and mechanical stability of the electronic devices are.

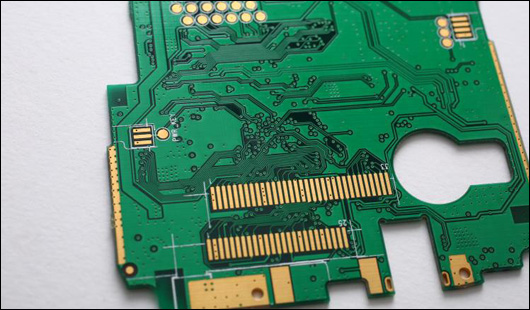

High-TG PCBs exist excellent heat dissipation for multi-layered PCBs and HDI PCBs. These PCBs will produce more heat because the components in multi-layered PCBs and HDI PCBs are more compact, and the circuits are very dense. High-TG PCBs are good at heat controlling and help to ensure the reliability of the products during operation.

We all know that if the electronics often work for a long time, the heat generated during the working process will pass to other parts, and affect the durability and performance of the product at last. For the electronics in some applications with multi-function but having the limitation of size and weight, high-TG PCBs would be the cost-effective ways to improve the efficiency of the thermal management.

APOLLOPCB is capable of offering FR4 or other high-TG PCBs that meet the needs of your PCB project. If you are not sure whether your applications need high-TG PCBs or other requirements, contact us. Professional engineers from APOLLOPCB will help you to analyze the project and offer you proper suggestions.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB