-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

Real PCB &PCB Assembly Manufacturer

IS09001:2015 Standard

UL.RoHS. REACH Certified

3000+ Orders/Day

99% on-time Shipping

100,000+ Customers

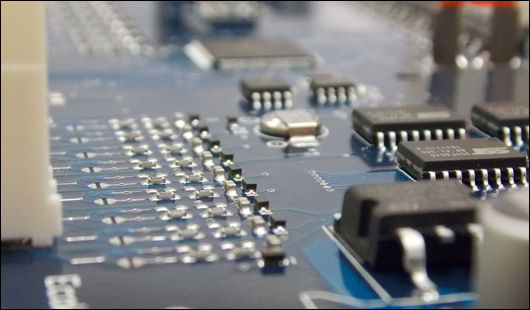

SMT, the full name is surface mount technology. SMT is a way to mount the components or parts onto the boards. Due to the better outcome and higher efficiency, SMT has become the primary approach used in the process of PCB assembly.

In the past, PCB manufacturers mainly used through-hole assembly to install components. But SMT has replaced the former assembly method with welding technology. And you can find the PCBs manufactured through SMT assembly procedure in all electronic industries, such as computers, telecommunications, smartphones, household appliances, etc. The general process of SMT assembly includes printing solder paste, mounting components, reflow soldering, AOI, or AXI.

The advantages of SMT assembly

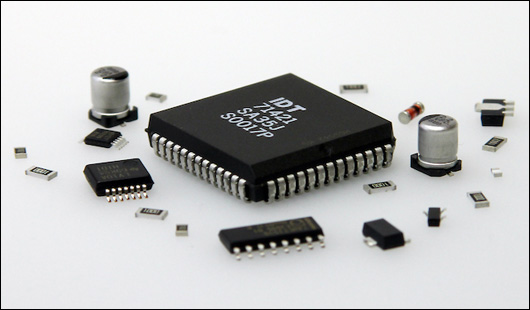

· Small size and lightweight

Using SMT technology to assemble the components onto the board directly helps to reduce the entire size and the weight of the PCBs. This assemble method allows us to place more components in a restricted space, which can achieve compact designs and better performance.

· High reliability

After the prototype is confirming, the entire SMT assembly process is almost automated with precise machines, making it minimizes the errors that may be caused by manual involvement. Thanks to the automation, SMT technology ensures the reliability and consistency of the PCBs.

· Cost-saving

SMT assemble usually realizes through automatic machines. Though the input cost of the machines is high, the automatic machines help to reduce manual steps during SMT processes, which significantly improves the production efficiency and lower the labor costs in the long-run. And there are fewer materials used than through-hole assemble, and the cost would be decreased, too.

SMT assembly capabilities of APOLLOPCB

APOLLOPCB owns a completely computerized SMT workshop for mass production. For the small batch orders, prototyping, or the complicated parts, we also provide manual welding service. We have several PCB types for assembly: FR4 board, aluminum board, flexible board, rigid-flex board. Except for SMT assembly, other assembly types such as BGA assembly, through-hole assembly, mixed assembly, and kit assembly are also available. When you place SMT orders, you should provide these files: Gerber file (used for PCB fabrication), BOM (bill of materials) list, CPL (component placement list) file, or PNP (Pick & Place) file.

APOLLOPCB has a professional team to provide turnkey service for SMT orders. Our engineers are specialized in every step in PCB manufacturing and PCB SMT prototype. No matter you offer the components, or we provide the components, all the components and SMT process are carefully checked and matched according to your design and requests.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB