-

- PCB TYPE

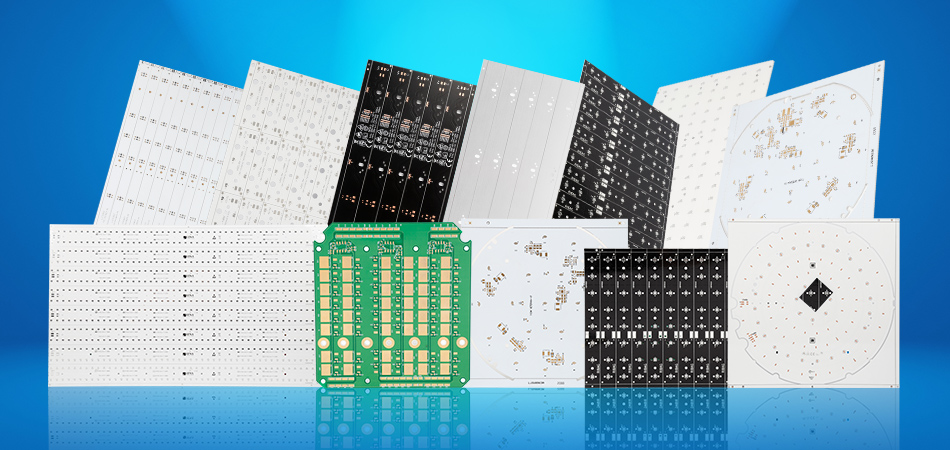

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 16. 2025, 09:24:59

In the dynamic landscape of modern electronics, Printed Circuit Boards (PCBs) are the backbone that interconnects and powers a vast array of devices. Among the diverse range of PCB options, the 2oz Copper Base Metal PCB has emerged as a game - changer, offering enhanced electrical and thermal capabilities. As the demand for more powerful, compact, and reliable electronic devices continues to soar across industries, understanding the nuances of 2oz copper - based PCBs becomes crucial. This article delves deep into the world of 2oz Copper Base Metal PCBs, exploring their unique features, design considerations, manufacturing processes, applications, market trends, and future prospects.

Understanding 2oz Copper Base Metal PCBs

Definition and Basics

A 2oz Copper Base Metal PCB is a type of printed circuit board where the copper layer, which serves as the primary conductor for electrical signals and heat transfer, has a thickness equivalent to 2 ounces of copper per square foot of the board area. This thickness measurement is a standard in the PCB industry and is a key determinant of the board's performance characteristics.

The copper layer in these PCBs is typically laminated onto a substrate material, which provides mechanical support and electrical insulation. The choice of substrate depends on the specific requirements of the application, such as thermal stability, flexibility, and cost - effectiveness.

Key Material Properties of 2oz Copper

High Electrical Conductivity

Copper is renowned for its excellent electrical conductivity, and a 2oz copper layer significantly enhances this property in PCBs. The increased thickness of the copper allows for a larger cross - sectional area for the flow of electrical current. This results in lower power losses during the transmission of electrical signals, enabling more efficient operation of electronic components. In high - power applications, such as power supplies and motor drives, the ability of 2oz copper to carry large currents with minimal resistance is of utmost importance.

Superior Thermal Conductivity

Heat management is a critical aspect in modern electronics, and 2oz copper layers excel in this area. Copper has a high thermal conductivity, meaning it can rapidly transfer heat. In a PCB, heat generated by components like integrated circuits and power transistors can be efficiently dissipated through the 2oz copper layer. The heat is first conducted from the components to the copper layer and then spread across the surface of the copper. This helps to prevent localized overheating, which can lead to component failure and reduced device lifespan. In applications where components operate at high temperatures, such as in automotive engine control units or industrial power electronics, the thermal conductivity of 2oz copper is a key advantage.

Mechanical Strength

In addition to its electrical and thermal properties, the 2oz copper layer contributes to the mechanical strength of the PCB. Copper is a relatively strong and ductile metal, and the thicker layer provides enhanced resistance to mechanical stress. This makes 2oz Copper Base Metal PCBs more durable and suitable for applications where the PCB may be subject to vibrations, shocks, or bending forces. For example, in automotive and aerospace applications, where the PCB must withstand harsh environmental conditions, the mechanical strength provided by the 2oz copper layer is highly beneficial.

Design Considerations for 2oz Copper Base Metal PCBs

Thermal Design

Heat Transfer Path Optimization

In designing a 2oz Copper Base Metal PCB for optimal thermal performance, the layout of components and the creation of efficient heat transfer paths are crucial. Heat - generating components should be placed in close proximity to the 2oz copper layer or connected to it via thermal vias. Thermal vias are small holes in the PCB that are filled with copper, providing a direct path for heat to flow from the component to the copper layer. By carefully routing these vias and ensuring a sufficient number of them, the heat transfer efficiency can be maximized. Additionally, the use of heat sinks in combination with the 2oz copper layer can further enhance heat dissipation. Heat sinks are typically made of materials with high thermal conductivity, such as aluminum or copper, and are designed to increase the surface area available for heat transfer to the surrounding environment.

Component Placement for Thermal Management

Proper component placement is essential for effective thermal management in 2oz Copper Base Metal PCBs. Components that generate a significant amount of heat, such as power - intensive integrated circuits and power transistors, should be spaced out to allow for adequate air circulation. In applications where forced - air cooling is used, the layout of components should be designed to optimize the flow of cooling air. This may involve placing components in a way that directs the air over the hottest components first and then across other components. Additionally, components that are sensitive to temperature should be placed away from heat - generating components to prevent thermal stress.

Electrical Design

Trace Routing and Impedance Control

In the electrical design of 2oz Copper Base Metal PCBs, trace routing plays a crucial role in ensuring signal integrity. For high - speed signals, impedance - controlled traces are essential. The impedance of a trace is determined by factors such as its width, length, the distance between adjacent traces, and the dielectric constant of the substrate material. In a 2oz copper - based PCB, the thicker copper layer can affect the impedance calculations. Designers must carefully calculate and maintain the appropriate impedance values for the traces to minimize signal reflections and crosstalk. This may involve using specialized software tools to simulate the electrical behavior of the PCB layout and making adjustments to the trace routing and dimensions as needed.

Power and Ground Plane Design

Power and ground planes are integral parts of the electrical design of 2oz Copper Base Metal PCBs. The 2oz copper layer can often be utilized as a power or ground plane, taking advantage of its low resistance and high conductivity. Well - designed power and ground planes help to distribute electrical power evenly across the PCB and provide a stable return path for electrical current. To ensure optimal performance, power and ground planes should be continuous, with minimal splits or gaps. Additionally, proper grounding techniques, such as star - grounding or 多点接地,should be employed to reduce electromagnetic interference (EMI) and improve the overall electrical performance of the PCB.

Manufacturing Processes of 2oz Copper Base Metal PCBs

Material Selection and Preparation

The manufacturing process of 2oz Copper Base Metal PCBs begins with the careful selection of materials. High - quality copper foil with a thickness equivalent to 2oz per square foot is chosen for its superior electrical and thermal properties. The copper foil is inspected for any defects, such as scratches, holes, or impurities, which could affect the performance of the final PCB. The substrate material, whether it is FR - 4, polyimide, or a metal - core material, is also selected based on the specific requirements of the application. Once the materials are selected, the copper foil and substrate are prepared for further processing. This may involve cleaning the surfaces to remove any contaminants and applying a bonding agent to ensure a strong bond between the copper and the substrate during lamination.

Lamination

Lamination is a critical step in the manufacturing of 2oz Copper Base Metal PCBs. In this process, the copper foil is bonded to the substrate material under high heat and pressure. The layers are carefully aligned to ensure accurate registration of the electrical traces and vias. The lamination process typically involves using a prepreg material, which is a resin - impregnated fiberglass or other insulating material. The prepreg is placed between the copper foil and the substrate, and when heat and pressure are applied, the resin cures, forming a strong bond between the layers. Precise control of the lamination parameters, such as temperature, pressure, and time, is essential to ensure a uniform and reliable bond. Any defects in the lamination, such as voids or delaminations, can significantly impact the performance and reliability of the PCB.

Drilling and Plating

After lamination, drilling is performed to create holes for vias, component mounting, and electrical connections. High - precision drilling machines are used to ensure accurate hole placement and clean hole walls. The holes are then plated with copper to create electrical connections between the different layers of the PCB and to provide a solderable surface for component attachment. Electroplating is a common method used for copper plating, where an electrical current is passed through the PCB in a copper - containing electrolyte solution. The copper ions in the solution are deposited onto the surface of the holes and the traces, forming a continuous conductive layer. The plating process requires careful control of parameters such as the current density, plating time, and temperature to ensure a uniform and thick copper deposit.

Circuit Patterning

Circuit patterning is the process of creating the electrical circuits on the surface of the 2oz copper layer. Photolithography is a widely used technique for circuit patterning. In this process, a photosensitive resist material is applied to the copper surface. A patterned mask, which contains the desired circuit pattern, is then placed over the resist - coated copper and exposed to ultraviolet (UV) light. The exposed areas of the resist are chemically altered and can be removed during the development process, leaving behind the unexposed resist in the shape of the circuit pattern. The remaining copper is then etched away using an etching solution, leaving only the copper traces that form the electrical circuits. The circuit patterning process requires high - resolution masks and precise control of the exposure and etching parameters to ensure accurate and fine - line circuit patterns.

Applications of 2oz Copper Base Metal PCBs

Power Electronics

In the field of power electronics, 2oz Copper Base Metal PCBs are extensively used. In power supplies, they are crucial for handling high currents and dissipating the heat generated by power - intensive components such as rectifiers, regulators, and power transistors. The high electrical conductivity of the 2oz copper layer reduces power losses during the conversion and distribution of electrical power, while the excellent thermal conductivity helps to keep the components cool, ensuring reliable operation. In inverters, which convert direct current (DC) to alternating current (AC), and converters, which change the voltage or current levels, 2oz Copper Base Metal PCBs enable efficient power transfer and heat management, contributing to the overall performance and lifespan of the devices.

Automotive Electronics

The automotive industry has embraced 2oz Copper Base Metal PCBs for a variety of applications. In engine control units (ECUs), these PCBs are used to handle the complex electrical and thermal requirements. The high - temperature environment under the hood of a vehicle demands PCBs that can effectively dissipate heat and maintain stable electrical performance. The 2oz copper layer in the PCB helps to transfer the heat generated by the ECU's components, such as microcontrollers and power drivers, to the surrounding environment, preventing overheating and ensuring reliable operation. In electric vehicles (EVs), 2oz Copper Base Metal PCBs are used in battery management systems, motor control units, and charging systems. In battery management systems, they are responsible for monitoring and controlling the charging and discharging of the battery pack, while in motor control units, they enable the efficient control of the electric motor. The high - power handling capabilities and thermal management properties of 2oz Copper Base Metal PCBs are essential for the safe and efficient operation of EVs.

Industrial Electronics

In industrial applications, 2oz Copper Base Metal PCBs find widespread use in equipment such as industrial automation systems, power distribution panels, and high - power motor drives. In industrial automation, these PCBs are used to control and monitor the operation of various machines and processes. They need to be able to withstand harsh environmental conditions, including high temperatures, vibrations, and electromagnetic interference. The mechanical strength provided by the 2oz copper layer, along with its electrical and thermal properties, makes it suitable for such applications. In power distribution panels, 2oz Copper Base Metal PCBs are used to distribute electrical power to different parts of the industrial facility. The high - current - carrying capacity of the 2oz copper layer ensures reliable power distribution, while the thermal conductivity helps to dissipate the heat generated during power transmission. In high - power motor drives, which are used to control the speed and torque of large electric motors, 2oz Copper Base Metal PCBs enable efficient power conversion and heat management, contributing to the smooth operation of the motors.

Market Trends of 2oz Copper Base Metal PCBs

Market Growth

The market for 2oz Copper Base Metal PCBs has been experiencing steady growth in recent years. This growth is driven by the increasing demand for high - performance electronics in various industries. The rise of electric vehicles, the expansion of renewable energy systems, and the development of advanced industrial automation technologies have all contributed to the growing need for PCBs with enhanced electrical and thermal capabilities. As these industries continue to evolve and demand more powerful and efficient electronic devices, the market for 2oz Copper Base Metal PCBs is expected to expand further. Additionally, the trend towards miniaturization and integration of electronic components has led to a greater reliance on PCBs that can handle higher power densities in a compact form factor, which is where 2oz Copper Base Metal PCBs excel.

Competitive Landscape

The market for 2oz Copper Base Metal PCBs is highly competitive, with a large number of manufacturers vying for market share. Key players in the market include both established global PCB manufacturers and emerging regional players. Competition is based on factors such as product quality, performance, cost - effectiveness, and delivery times. Manufacturers are constantly investing in research and development to improve the manufacturing processes of 2oz Copper Base Metal PCBs, reduce costs, and enhance product performance. They are also focusing on providing customized solutions to meet the specific requirements of different customers and industries. In addition, the ability to comply with international standards and regulations, such as environmental regulations and quality management standards, is becoming increasingly important in the competitive landscape.

Challenges and Future Trends

Challenges

Despite the numerous advantages of 2oz Copper Base Metal PCBs, there are several challenges that need to be addressed. One of the main challenges is the cost of copper. Copper is a relatively expensive metal, and the use of a 2oz copper layer in PCBs can significantly increase the material cost. Additionally, the manufacturing process of 2oz Copper Base Metal PCBs is more complex and time - consuming compared to standard PCBs. The lamination process, for example, requires more precise control of parameters to ensure a strong bond between the thicker copper layer and the substrate. The drilling and plating processes also pose challenges due to the increased thickness of the copper. Another challenge is the need for more advanced design tools and techniques to optimize the performance of 2oz Copper Base Metal PCBs. As the demand for higher - performance and more compact electronic devices continues to grow, designers need to be able to accurately predict and simulate the electrical and thermal behavior of these PCBs.

Future Trends

Looking ahead, the future of 2oz Copper Base Metal PCBs is promising. Advancements in materials science are expected to lead to the development of new copper - based alloys or alternative materials that offer even better electrical and thermal properties at a lower cost. For example, the use of nanocomposite materials or advanced copper - clad laminates may provide enhanced performance while reducing the overall cost of the PCB. In terms of manufacturing, the adoption of advanced manufacturing technologies such as additive manufacturing (3D printing) may revolutionize the production of 2oz Copper Base Metal PCBs. Additive manufacturing can potentially enable more complex and customized designs, reduce material waste, and shorten the production cycle. The integration of new technologies such as 5G, artificial intelligence, and the Internet of Things (IoT) is also expected to drive the demand for 2oz Copper Base Metal PCBs. These technologies require high - performance PCBs that can handle the increased data processing and power requirements, and 2oz Copper Base Metal PCBs are well - positioned to meet these demands.

Conclusion

2oz Copper Base Metal PCBs have emerged as a vital technology in the modern electronics industry, offering a combination of high electrical conductivity, superior thermal management, and mechanical strength. Their applications span across a wide range of industries, from power electronics and automotive to industrial automation. As the demand for more powerful, compact, and reliable electronic devices continues to grow, 2oz Copper Base Metal PCBs will play an increasingly important role. While there are challenges to overcome, such as cost and manufacturing complexity, ongoing advancements in materials science and manufacturing technologies hold great promise for the future of these high - performance PCBs. By addressing these challenges and capitalizing on emerging trends, the 2oz Copper Base Metal PCB market is set to experience continued growth and innovation in the coming years.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB