-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 17. 2025, 12:40:15

3mm Counterbore Sinkpad PCB emerges as a specialized solution for miniaturized high-power electronics, combining the structural stability of flat-bottomed counterbore holes with the thermal efficiency of sinkpad technology. Unlike tapered countersink designs that prioritize surface flushness, 3mm counterbores feature cylindrical recesses with straight walls and flat bases—engineered to accommodate socket head cap screws, hex bolts, and heavy components requiring robust mechanical fastening. This unique geometry addresses a critical gap in compact electronics: maintaining reliable thermal transfer while supporting secure, vibration-resistant mounting in space-constrained environments. For applications ranging from miniature industrial controllers to portable medical devices, the 3mm dimension strikes an optimal balance between fastening strength, thermal performance, and design miniaturization. This article explores the precision design principles, performance advantages, targeted use cases, manufacturing criticalities, and innovative advancements of 3mm Counterbore Sinkpad PCBs.

The performance of 3mm Counterbore Sinkpad PCBs is rooted in three core design pillars tailored to the unique constraints of miniaturized high-power systems:

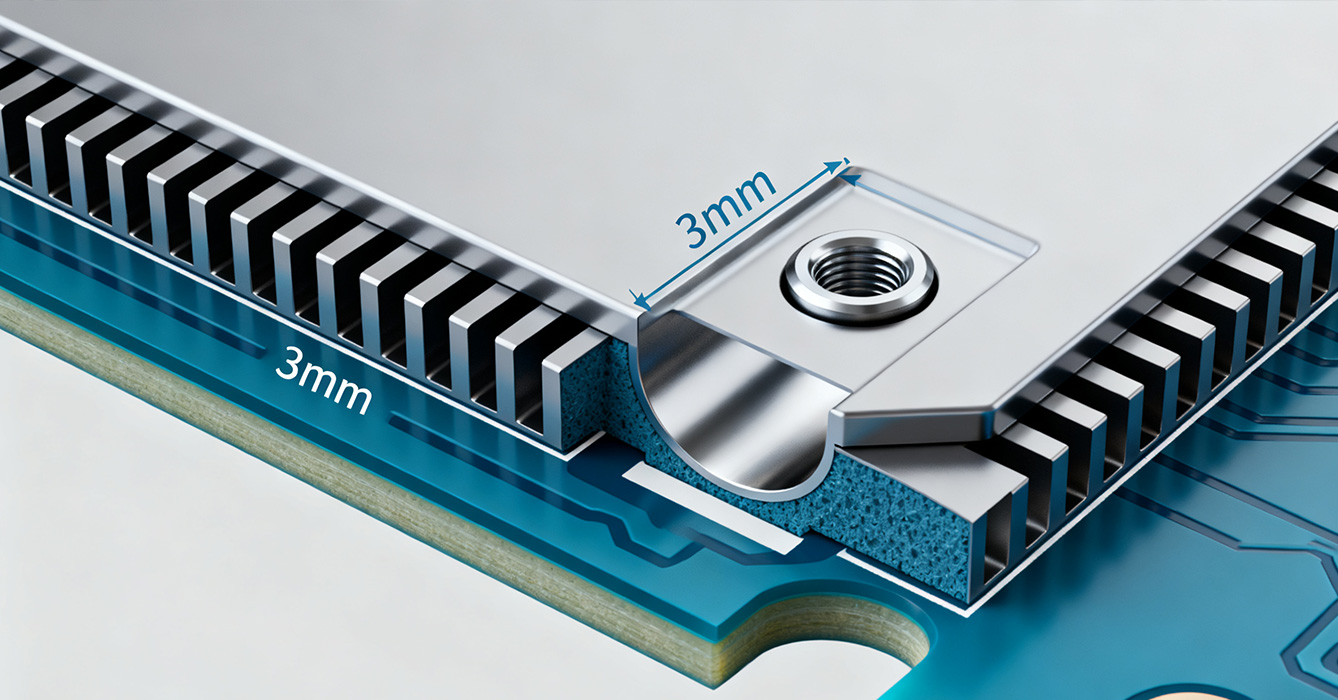

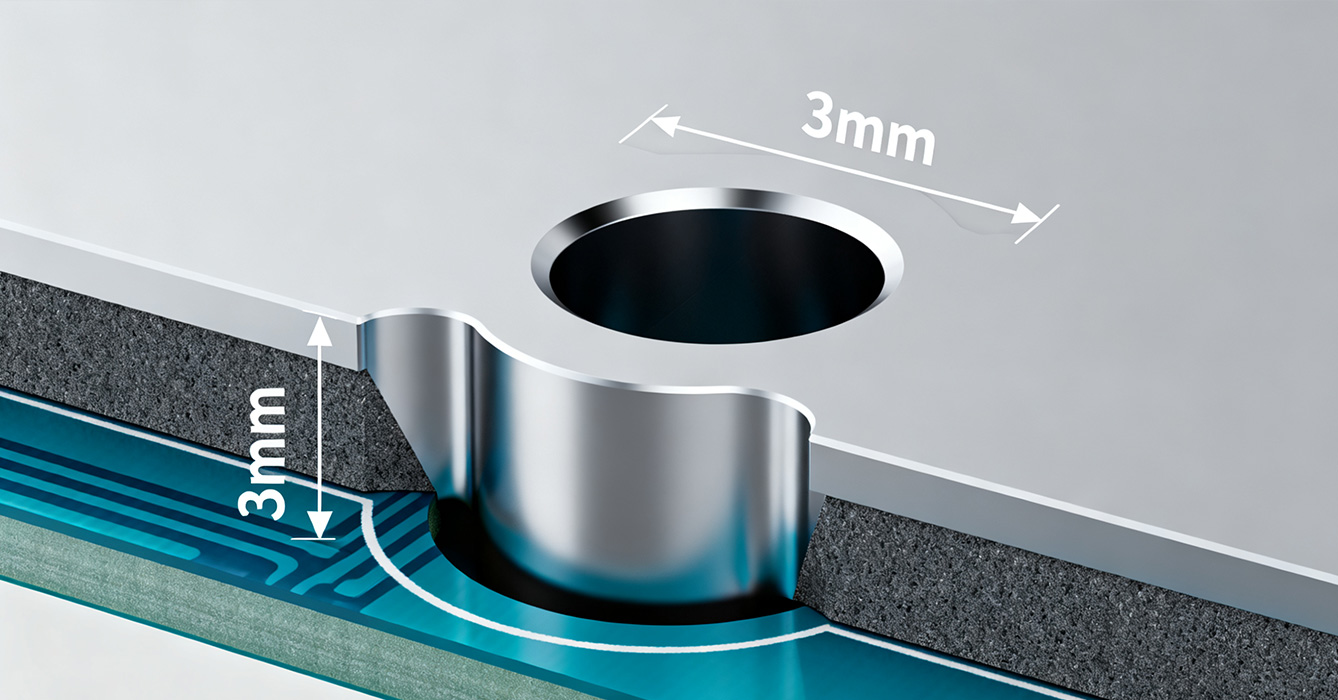

Contiguous Thermal Interface: The 3mm counterbore’s flat bottom ensures full contact between the component’s thermal base and the sinkpad’s metal core (copper, aluminum alloy, or CuW), eliminating air gaps that degrade heat transfer. Unlike tapered countersinks, the cylindrical profile distributes thermal energy evenly across the sinkpad surface .

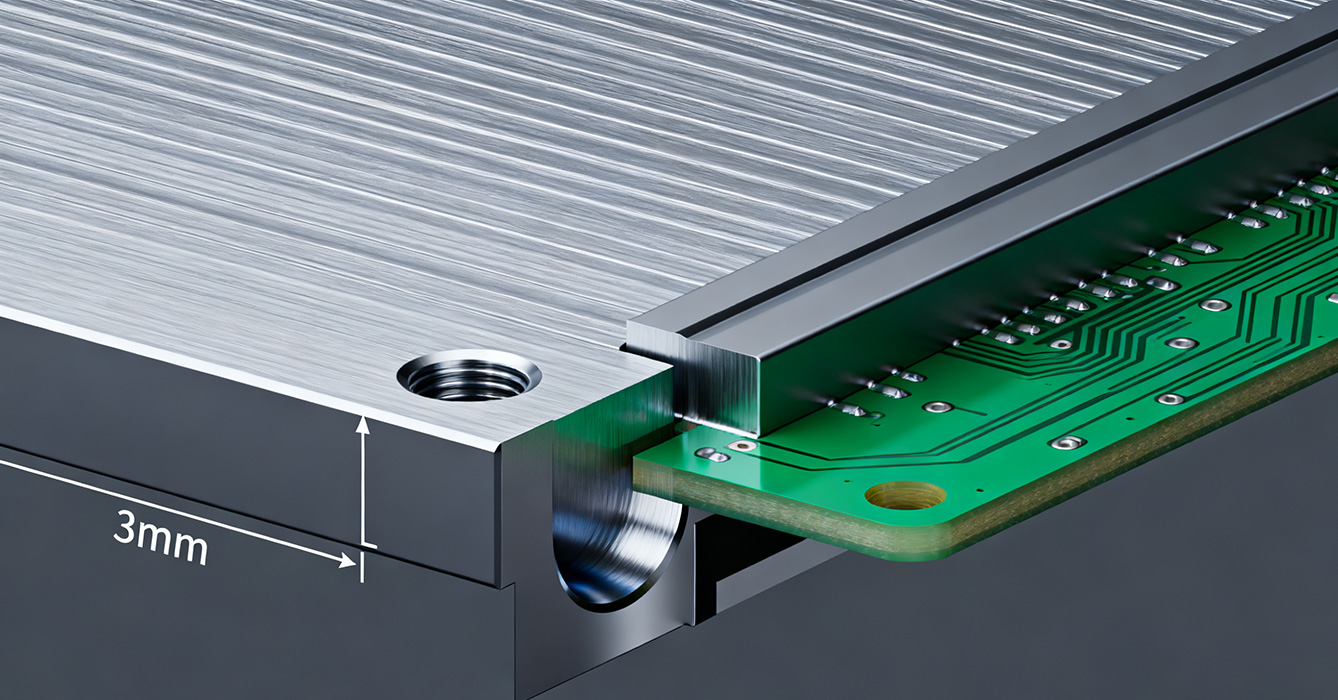

Mechanical Load Distribution: The straight-walled counterbore design disperses fastening torque and vibration forces across a wider area, reducing stress concentrations on solder joints and dielectric layers. This is critical for 3mm-scale applications where component weight relative to PCB size demands robust fixation .

Fastener Compatibility: The 3mm counterbore diameter is calibrated for M2-M3 socket head screws—industry-standard fasteners for compact high-power components (e.g., miniaturized SiC chips, high-density LEDs). This compatibility simplifies assembly and ensures interchangeability .

Material Conservation: The shallow, precise recess (typically 0.5–1.2mm depth) removes minimal sinkpad material, preserving structural integrity while accommodating screw heads below the PCB surface. This avoids compromising thermal conductivity or layer stability in thin PCBs .

Machinability Matching: Sinkpad materials are selected for compatibility with 3mm counterbore precision machining. 6061-T6 aluminum offers optimal balance of thermal conductivity and machinability, achieving Ra 0.8–1.6μm surface finishes with standard carbide tools .

Dielectric Layer Protection: The counterbore depth is engineered to stop short of the dielectric layer, maintaining electrical isolation between the metal core and signal layers while maximizing thermal contact area .

3mm Counterbore Sinkpad PCBs deliver four distinct benefits that outperform conventional designs in miniaturized high-power applications:

The flat-bottomed counterbore design provides 30–40% greater fastening stability than countersinks, resisting vibration-induced loosening in environments like portable industrial tools or drone power modules. This aligns with MIL-STD-810G vibration standards for ruggedized electronics .

Full-surface contact between the component and sinkpad reduces contact thermal resistance by 25–35% compared to tapered countersinks. For 20–50W miniaturized components (e.g., medical laser diodes), this translates to 10–15°C lower junction temperatures .

Recessing 3mm fastener heads below the PCB surface reduces assembly height by 15–20%, enabling stacking in compact enclosures. This is pivotal for wearable medical devices, miniaturized LED arrays, and portable power supplies .

Precision CNC machining of 3mm counterbores achieves dimensional tolerances of ±0.02mm, ensuring uniform component alignment across production batches. This reduces performance variability in high-volume applications like consumer electronics or industrial sensor modules .

3mm Counterbore Sinkpad PCBs excel in scenarios where miniaturization, mechanical stability, and thermal efficiency converge:

Compact servo drives and sensor modules use 3mm counterbores to secure high-power IGBTs, with vibration resistance ensuring reliable operation in factory automation systems. The design supports dense component placement without sacrificing thermal management .

Handheld laser therapy tools and diagnostic equipment leverage the space-saving design and uniform thermal conduction. 3mm counterbores secure high-power components in lightweight enclosures, while biocompatible materials (e.g., 316L stainless steel sinkpads) meet medical device standards .

Automotive interior lighting and portable projectors use 3mm Counterbore Sinkpad PCBs to mount high-power LEDs. The flat-bottomed design ensures consistent heat dissipation across dense arrays, preventing color shift or lumen degradation .

Weight-sensitive UAV propulsion systems rely on lightweight aluminum sinkpads with 3mm counterbores. The design balances mechanical ruggedness (resisting flight vibration) with thermal efficiency, extending battery life by reducing power loss from overheating .

To maximize performance, manufacturers must address three key considerations:

Use 5-axis CNC mills with diamond-tipped tools for 3mm counterbore machining, maintaining cutting speeds of 3000 rpm for aluminum and 1800 rpm for stainless steel to avoid material deformation .

Implement in-process laser profilometry to verify counterbore depth and surface finish, reducing scrap rates by 20–25% .

Aluminum sinkpads: Utilize minimum quantity lubrication (MQL) to prevent oxidation and maintain thermal conductivity.

Copper-tungsten sinkpads: Employ cryogenic machining to handle higher hardness, ensuring dimensional stability .

Post-machining inspection with optical coordinate measuring machines (CMMs) to validate diameter, depth, and concentricity.

X-ray testing to confirm dielectric layer integrity, preventing electrical short risks .

The evolution of 3mm Counterbore Sinkpad PCBs is driven by miniaturization and smart integration:

Micro-Channel Integration: 3mm counterbores with internal micro-channels for enhanced heat dissipation in ultra-high-power miniaturized components (e.g., 100W+ microprocessors).

Additive Manufacturing: 3D-printed hybrid sinkpads with customized 3mm counterbore geometries, optimizing thermal paths for specific component footprints.

Smart Fastening Sensing: Embedded strain gauges within counterbores to monitor fastening torque in real time, enabling predictive maintenance in critical applications .

3mm Counterbore Sinkpad PCBs redefine precision in miniaturized high-power electronics, merging the mechanical stability of flat-bottomed counterbores with the thermal efficiency of sinkpad technology. By optimizing the 3mm dimension for fastener compatibility, material machinability, and space conservation, this design addresses unmet needs in portable industrial tools, medical devices, LED arrays, and UAV systems. As electronics continue to shrink while demanding higher power densities, 3mm Counterbore Sinkpad PCBs will remain a critical enabler—proving that precision in small-scale design is the key to balancing performance, reliability, and miniaturization.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB