-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 01. 2025, 09:57:50

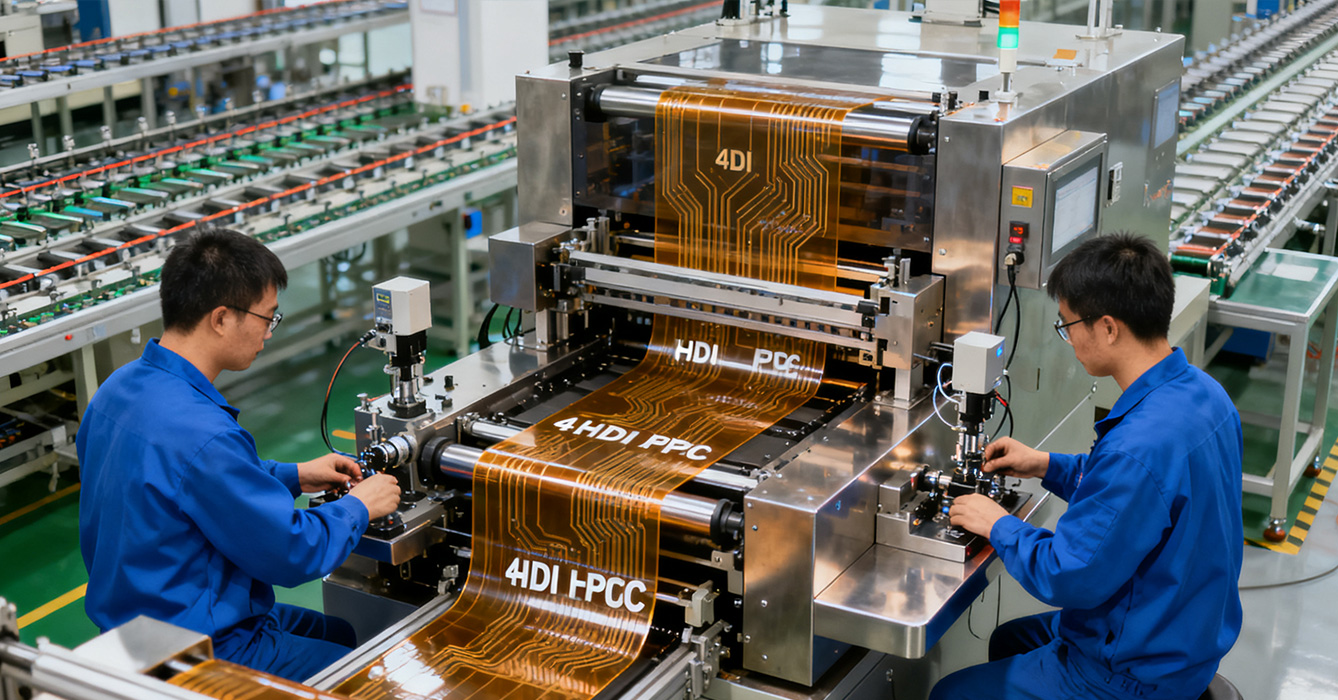

As electronic devices evolve toward ultra-miniaturization, high integration, and high-frequency operation, the demand for flexible printed circuits (FPCs) with superior density and signal performance has surged. A professional 4 Layer HDI FPC Manufacturer emerges as a critical enabler in this landscape, specializing in the production of 4-layer high-density interconnect (HDI) FPCs that combine the flexibility of traditional FPCs with the high-density routing capabilities of HDI technology. Unlike standard FPC manufacturers, these specialized providers possess unique expertise in optimizing 4-layer stackups, fabricating micro blind/buried vias, and ensuring signal integrity—key requirements for powering next-generation electronic products. For brands in high-end consumer electronics, medical devices, and automotive ADAS, partnering with a reputable 4 Layer HDI FPC Manufacturer is essential to translating innovative designs into high-performance, reliable products.

The value of a 4 Layer HDI FPC Manufacturer lies in its specialized technical capabilities, which address the unique challenges of 4-layer HDI FPC production:

- HDI Process Mastery: Top manufacturers excel in HDI core processes, including micro blind/buried via fabrication, fine-pitch trace etching, and precise layer lamination. These processes enable the creation of dense circuit layouts with reduced via sizes and tighter trace spacing, maximizing the use of limited space on the 4-layer FPC. Advanced technologies such as laser drilling and plasma desmearing ensure via reliability and signal transmission efficiency, critical for high-frequency applications.

- 4-Layer Stackup Optimization: A skilled 4 Layer HDI FPC Manufacturer optimizes the 4-layer stackup design to balance signal integrity, mechanical flexibility, and thermal performance. By separating power, ground, and signal layers strategically, they minimize electromagnetic interference (EMI) and crosstalk—common challenges in high-density circuits. This optimization ensures that the 4-layer HDI FPC maintains stable performance even in high-speed data transmission scenarios, such as 5G-enabled devices or high-resolution display modules.

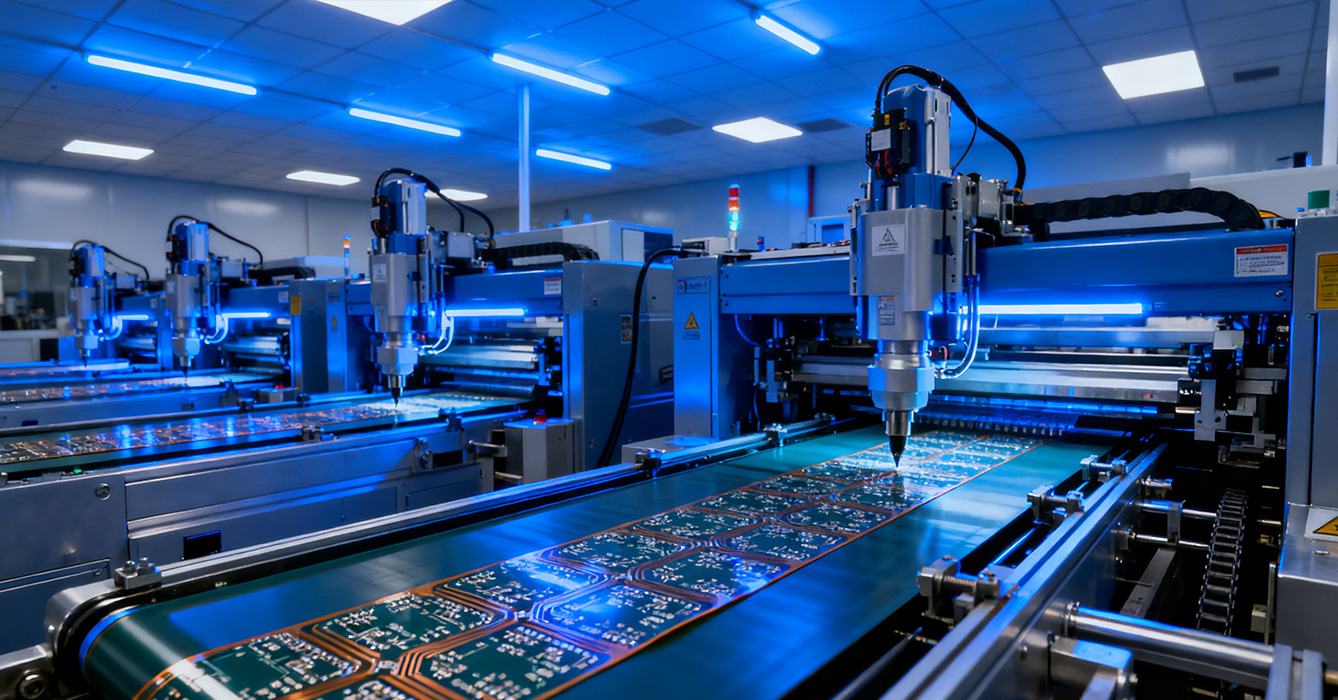

- Rigorous Quality Control for HDI Specifics: HDI FPCs demand stricter quality standards due to their complex structures. Leading manufacturers implement specialized quality control measures, including X-ray inspection for micro via integrity, automated optical inspection (AOI) for fine-pitch trace defects, and thermal cycling tests to validate layer adhesion. They also comply with international HDI standards such as IPC-6012/2221, ensuring consistent quality across production batches.

- Material Expertise for High-Density Applications: Selecting the right materials is crucial for 4-layer HDI FPC performance. Manufacturers leverage deep material knowledge to choose high-performance substrates (e.g., high-Tg polyimides) and conductive materials that offer excellent signal transmission, thermal resistance, and flexibility. For application-specific needs, they also integrate specialized materials such as low-loss dielectrics for high-frequency applications or biocompatible substrates for medical devices.

The unique combination of 4-layer structure and HDI technology addresses critical pain points in modern electronic design, making specialized manufacturers irreplaceable:

1. Enabling Ultra-Miniaturization: As devices become smaller (e.g., wearables, miniaturized medical sensors), standard FPCs struggle to accommodate the growing number of components and interconnections. 4-layer HDI FPCs, with their high-density routing and compact 4-layer stackup, allow more functions to be integrated into a smaller footprint—supporting the trend toward slim, lightweight electronic products.

2. Ensuring High-Frequency Signal Integrity: Next-generation devices (e.g., 5G smartphones, ADAS radar modules) rely on high-speed data transmission. The optimized 4-layer stackup and HDI processes used by specialized manufacturers minimize signal loss and EMI, ensuring that signals are transmitted accurately and reliably even at high frequencies. This is a capability that standard FPC manufacturers often cannot match.

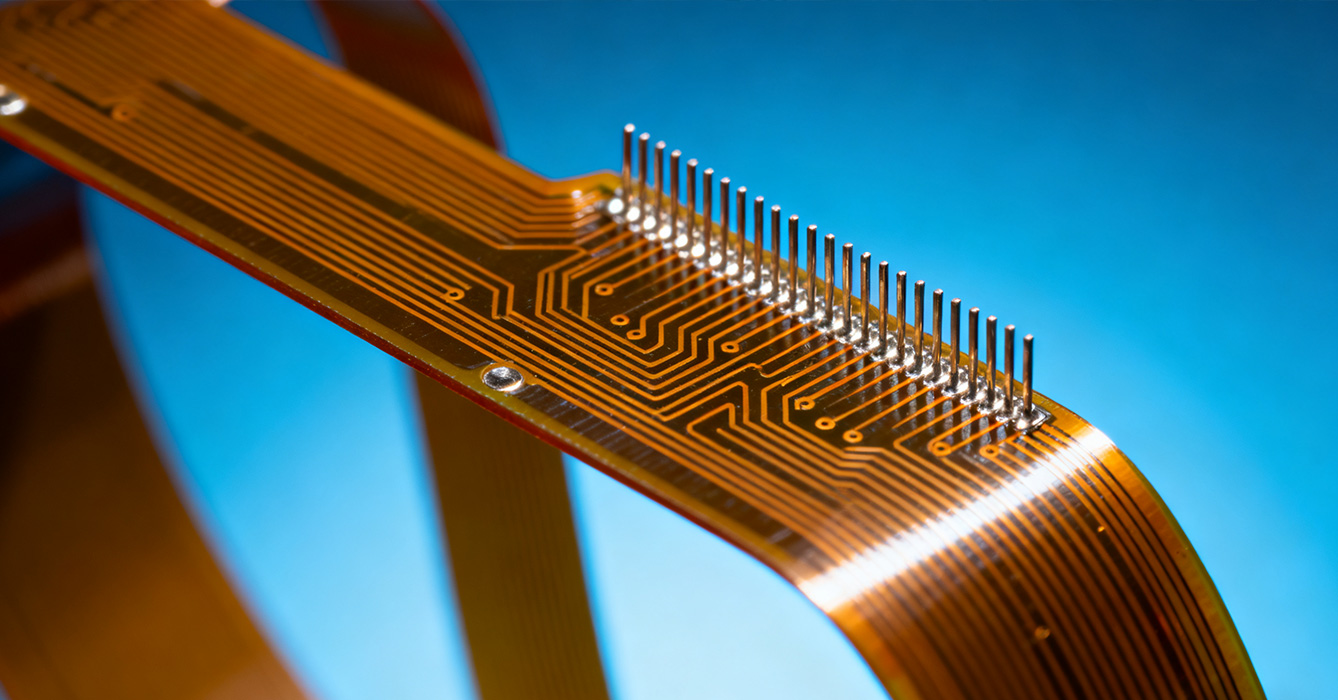

3. Balancing Flexibility and Structural Stability: Unlike rigid HDI PCBs, 4-layer HDI FPCs maintain the flexibility required for curved or dynamic applications (e.g., foldable device hinges, robotic arms). Manufacturers achieve this balance by optimizing material selection and layer thickness, ensuring that the 4-layer structure does not compromise the FPC’s ability to bend and twist without structural damage.

4. Supporting Complex Function Integration: Modern electronic products often combine multiple functions (e.g., sensing, display, wireless communication) in a single device. 4-layer HDI FPCs provide the necessary interconnection density to integrate these functions seamlessly, reducing the number of components and assembly steps. This simplifies manufacturing, lowers costs, and improves product reliability.

4 Layer HDI FPC Manufacturers cater to high-end electronic sectors where density, performance, and flexibility are non-negotiable:

- High-End Consumer Electronics: Powers foldable smartphones, premium smartwatches, and high-resolution VR/AR devices. 4-layer HDI FPCs enable the integration of multiple sensors, display drivers, and wireless modules in tight spaces, supporting advanced features such as foldable screens and 5G connectivity.

- Automotive ADAS & EV Systems: Supplies 4-layer HDI FPCs for ADAS cameras, radar/lidar modules, and EV powertrain controls. These FPCs withstand extreme temperatures and vibration while ensuring high-speed signal transmission between critical components, enhancing driving safety and EV performance.

- Medical Devices: Delivers miniaturized 4-layer HDI FPCs for implantable sensors, minimally invasive surgical tools, and portable diagnostic equipment. The high-density design supports precise sensor integration and data transmission, while biocompatible materials ensure patient safety.

- Aerospace & Industrial IoT: Provides high-reliability 4-layer HDI FPCs for aerospace avionics and industrial IoT sensors. These FPCs offer weight reduction, high signal integrity, and resistance to harsh environments (radiation, extreme temperatures), meeting the strict requirements of these sectors.

In conclusion, a 4 Layer HDI FPC Manufacturer is a specialized partner that empowers the development of next-generation high-performance electronic products. By mastering HDI processes, optimizing 4-layer stackups, and ensuring rigorous quality control, these manufacturers deliver FPCs that balance density, flexibility, and signal performance. As the electronics industry continues to push the boundaries of miniaturization and high-frequency operation, the role of 4 Layer HDI FPC Manufacturers will become increasingly critical. For brands seeking to innovate in high-end sectors, partnering with a reputable 4 Layer HDI FPC Manufacturer is a strategic investment in product performance, reliability, and market competitiveness.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB