-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 10. 2025, 19:09:36

The development of 5G technology is reshaping the landscape of communication and connectivity. At the heart of this revolution lies the intricate process of 5G antenna PCB manufacturing. This article delves into the nuances of this critical process, exploring the steps involved in manufacturing, the importance of precise PCB fabrication, and the role of PCB assembly services in bringing 5G technology to life.

5G antenna PCB manufacturing refers to the creation of printed circuit boards (PCBs) that are specifically designed to support 5G antenna technology. These PCBs are integral to the functioning of 5G networks, as they facilitate the transmission and reception of high-frequency signals. The design and manufacture of these boards require precision and sophistication to handle the higher frequency and bandwidth demands of 5G technology.

PCB fabrication is a multi-step process that transforms a design into a physical board. Here's a closer look at the key stages:

The initial stage involves designing the PCB layout using specialized software. This design includes the placement of components, signal routing, and power distribution. The layout must be meticulously planned to ensure it meets the specific requirements of 5G antenna technology.

Choosing the right materials is crucial. For 5G antenna PCBs, materials with high-frequency capabilities, such as Rogers or Teflon, are often used. These materials help reduce signal loss and improve performance.

Once the design is finalized, the layering process begins. Multiple layers of copper and other materials are laminated together. The etching process then removes excess copper, leaving behind the desired circuit pattern.

Holes are drilled into the board to accommodate component leads and vias. These holes are then plated with copper to ensure electrical connectivity between layers.

A solder mask is applied to protect the board and prevent solder bridging. The silkscreen layer is added to label components and provide assembly instructions.

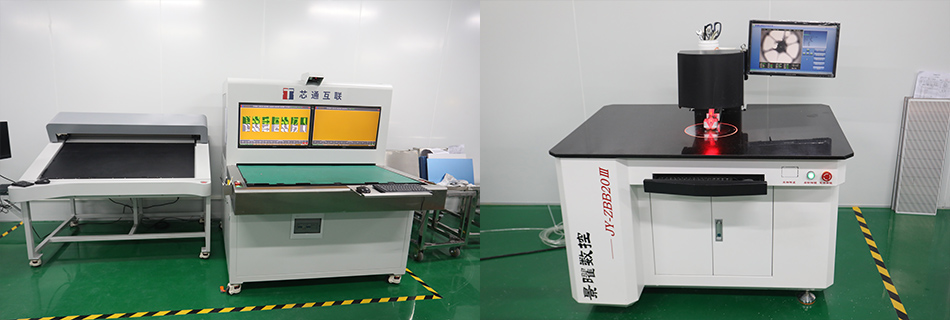

Before the board is finalized, it undergoes rigorous testing to ensure it meets quality standards. This includes electrical testing to check for shorts and opens, as well as visual inspections.

PCB assembly services are critical in the manufacturing process, where components are mounted onto the fabricated board. Here’s how these services contribute to 5G antenna PCB manufacturing:

Automated machines place components onto the board with precision. This step is crucial for the high-frequency performance of 5G antennas, where even minor misalignments can affect signal integrity.

Soldering attaches the components to the board. Techniques like surface mount technology (SMT) and through-hole soldering are used, depending on the component type and board design.

After assembly, the board undergoes inspection and testing to ensure it functions correctly. Advanced testing methods like automated optical inspection (AOI) and X-ray inspection are often employed to verify component placement and solder quality.

Manufacturing PCBs for 5G antennas presents unique challenges:

5G technology operates at higher frequencies, requiring PCBs that can handle these signals without significant loss. This demands precise material selection and design techniques.

As devices become smaller, PCBs must be designed to fit into compact spaces without compromising performance. This calls for innovative design solutions and advanced manufacturing techniques.

5G PCBs generate more heat due to higher power levels. Effective thermal management solutions, such as heatsinks and thermal vias, are essential to prevent overheating and ensure reliable operation.

As 5G technology continues to evolve, so does the field of PCB manufacturing. Here are some trends shaping the future:

Research into new materials that offer better performance and reliability is ongoing. These materials aim to reduce signal loss and improve heat dissipation.

Automation in PCB manufacturing is increasing, with AI playing a role in design optimization and quality control. This enhances efficiency and reduces human error.

The industry is moving towards more sustainable practices, using eco-friendly materials and processes to minimize environmental impact.

5G antenna PCB manufacturing is a complex yet fascinating process that plays a vital role in the development of 5G technology. From meticulous design and material selection to precise assembly and testing, each step is crucial in ensuring the performance and reliability of 5G networks. As technology advances, the PCB manufacturing industry will continue to innovate, driving the future of connectivity.

By understanding these processes and challenges, manufacturers can better equip themselves to meet the demands of the rapidly evolving 5G landscape, ultimately delivering cutting-edge technology to consumers worldwide.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB