-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 11. 2025, 09:10:15

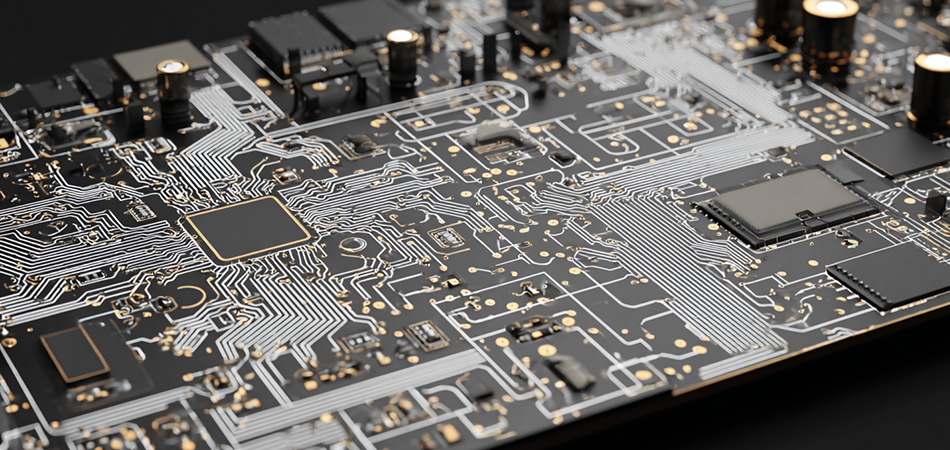

In the rapidly evolving realm of electronics, printed circuit boards (PCBs) serve as the silent architects that underpin the functionality of countless devices. Among the diverse array of PCB technologies, aluminum base PCBs have emerged as a transformative force, offering a unique synergy of thermal management, mechanical resilience, and electrical reliability. This article delves deep into the intricacies of aluminum base PCBs, exploring their fundamental principles, design methodologies, manufacturing processes, real - world applications, and emerging trends, highlighting their pivotal role in shaping the future of electronic engineering.

The Foundation of Aluminum Base PCBs: Material Science

Aluminum Substrate: A Multifaceted Core

The aluminum substrate lies at the heart of aluminum base PCBs, endowing them with distinct advantages that set them apart from traditional PCBs. Its high thermal conductivity is a game - changer, providing an efficient pathway for dissipating the heat generated by power - hungry electronic components. In electronic devices, overheating can lead to performance degradation, component failure, and reduced lifespan. The aluminum substrate acts as a heat sink, rapidly transferring heat away from critical components, ensuring they operate within their optimal temperature range.

Beyond thermal management, aluminum's favorable strength - to - weight ratio offers mechanical stability. It can withstand mechanical stresses such as vibrations, shocks, and impacts, making it suitable for applications in harsh environments, from automotive electronics jostling on the road to aerospace systems enduring extreme conditions during flight. Additionally, aluminum's malleability allows for the creation of complex shapes and thin profiles, enabling designers to meet the diverse form factor requirements of modern electronic devices.

Dielectric Layers: Balancing Insulation and Heat Transfer

Sandwiched between the aluminum substrate and the copper conductive layers, the dielectric layers in aluminum base PCBs play a crucial dual role. As insulators, they prevent electrical short circuits between the aluminum core and the copper traces, ensuring the integrity of the electrical signals and power delivery within the circuit. This is essential for the proper functioning of the electronic components mounted on the PCB.

Simultaneously, these dielectric layers are engineered to have good thermal conductivity. They act as a thermal bridge, facilitating the transfer of heat from the components to the aluminum substrate. The choice of dielectric material is critical, as it directly impacts the thermal resistance of the PCB. High - quality dielectric materials, such as ceramic - filled epoxies or polyimides, are carefully selected to strike the right balance between electrical insulation and thermal transfer, optimizing the overall performance of the PCB.

Copper Layers: Conductive Pathways for Electronic Signals and Power

Copper, renowned for its excellent electrical conductivity, forms the conductive layers of aluminum base PCBs. These copper layers are patterned to create traces that serve as the pathways for both electrical signals and power transmission. For signal traces, precise routing is essential to ensure the integrity of data transmission, especially in high - frequency applications where signal interference can lead to errors.

Power traces, on the other hand, are designed to handle the currents required by the electronic components. They are engineered to have low resistance, minimizing power losses as heat during the transmission of electrical energy. The thickness and width of the copper traces are carefully optimized based on the power requirements of the components, ensuring a stable and efficient power supply.

Design Principles for Optimal Performance

Thermal Management Design

Effective thermal management is the cornerstone of successful aluminum base PCB design. Component placement is a key factor in this regard. Heat - generating components, such as integrated circuits, power transistors, and LEDs, should be positioned in areas that maximize heat transfer to the aluminum substrate. This direct contact reduces thermal resistance, allowing heat to flow more efficiently away from the components.

Thermal vias, small holes filled with a conductive material, are often incorporated into the design. These vias connect the upper copper layers to the aluminum base, creating additional pathways for heat to flow from the components to the heat - dissipating substrate. In some cases, the aluminum base itself may be designed with fins or other heat - dissipating features to enhance its cooling capabilities further. For high - power applications, external heat sinks or cooling fans may be integrated with the PCB to ensure that the components do not overheat.

Electrical Design

The electrical design of aluminum base PCBs focuses on ensuring reliable power delivery and signal integrity. Power distribution networks are carefully designed to provide a stable voltage and current to the components. This involves creating power planes, which are large areas of copper that distribute power evenly across the PCB, reducing voltage drops and ensuring that all components receive the necessary power.

For signal transmission, especially in high - speed digital circuits, impedance control is crucial. The traces are designed to have a specific impedance to match the requirements of the components, minimizing signal reflections and ensuring that the signals are transmitted accurately. Grounding strategies are also an important aspect of electrical design. A proper grounding scheme helps to reduce electromagnetic interference (EMI) and noise, improving the overall performance of the circuit.

Mechanical Design

Mechanical design considerations for aluminum base PCBs include the form factor, mounting options, and structural integrity. The PCB should be designed to fit seamlessly into the enclosure of the electronic device, with appropriate mounting holes and features. The thickness of the PCB, as well as the strength of the aluminum substrate, needs to be considered to ensure that it can withstand the mechanical stresses of handling, installation, and operation.

In addition, the mechanical design should take into account the need for component protection. This may involve adding mechanical supports or enclosures to protect sensitive components from damage. The design should also facilitate the assembly process, making it easy to mount components onto the PCB and connect it to other parts of the electronic device.

Manufacturing Processes for Precision and Quality

Substrate Preparation

The manufacturing process of aluminum base PCBs begins with substrate preparation. The aluminum substrate is first cut to the desired size and shape using precision cutting techniques, such as CNC machining or laser cutting. After cutting, the surface of the aluminum substrate undergoes a series of treatments, including cleaning, degreasing, and surface roughening. These surface treatments are essential for improving the adhesion of the dielectric layers, ensuring a strong and reliable bond between the layers.

Dielectric Layer Lamination

Once the substrate is prepared, the dielectric layers are laminated onto the aluminum surface. High - pressure lamination processes are used to bond the dielectric materials firmly to the aluminum substrate. The lamination process requires precise control of temperature, pressure, and time to achieve a uniform and defect - free bond. The quality of the lamination directly impacts the thermal and electrical performance of the PCB, as well as its mechanical strength.

Copper Layer Fabrication

The fabrication of the copper layers involves several steps. First, a copper foil is laminated onto the dielectric - coated aluminum substrate. Photolithography or laser direct imaging (LDI) techniques are then used to transfer the circuit pattern onto the copper foil. Chemical etching follows, selectively removing the unwanted copper to create the desired conductive traces and pads. The copper layer fabrication process requires high precision to ensure accurate trace widths and spacing, especially for fine - pitch designs.

Surface Finishing and Assembly

To protect the copper traces and improve solderability, surface finishing processes are applied. Common surface finishes for aluminum base PCBs include electroless nickel immersion gold (ENIG), organic solderability preservative (OSP), and hot air solder leveling (HASL). Each surface finish has its own advantages and is selected based on the specific requirements of the application.

Once the surface finishing is complete, the components are assembled onto the PCB using automated pick - and - place machines. Reflow soldering or wave soldering processes are then used to attach the components securely to the board. The assembly process requires careful control to ensure proper alignment and soldering of the components, as any defects in the assembly can lead to functional failures of the electronic device.

Diverse Applications of Aluminum Base PCBs

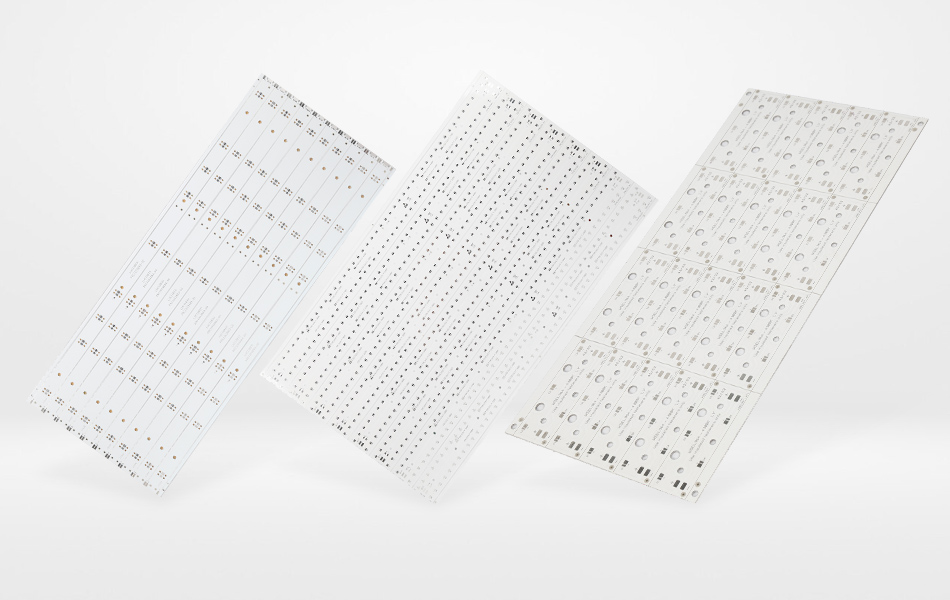

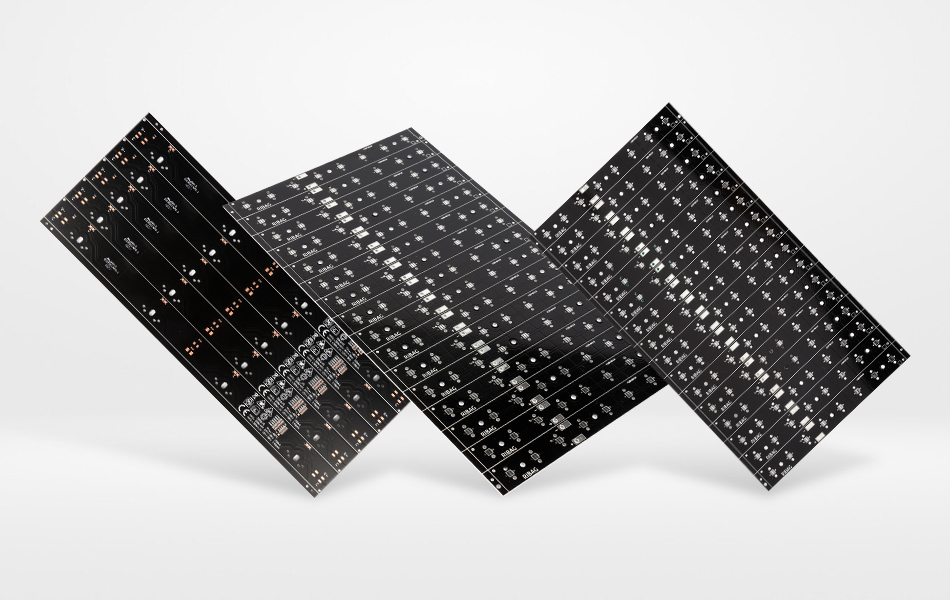

Lighting Systems

In the LED lighting industry, aluminum base PCBs have become the go - to choice. LEDs generate a significant amount of heat during operation, and effective thermal management is crucial for their performance and lifespan. The high thermal conductivity of the aluminum substrate in these PCBs ensures that the heat generated by the LEDs is quickly dissipated, preventing overheating and maintaining consistent light output.

Aluminum base PCBs also enable the creation of compact and lightweight LED lighting fixtures. Their mechanical strength allows them to withstand the rigors of installation and operation in various environments, from indoor residential and commercial lighting to outdoor streetlights and landscape lighting. Additionally, the design flexibility of these PCBs allows for the integration of advanced features such as dimming control and color - changing capabilities.

Power Electronics

Power electronics, including power supplies, inverters, and motor controllers, often deal with high - power components that generate a large amount of heat. Aluminum base PCBs are well - suited for these applications due to their excellent thermal management capabilities. They can handle the high currents and heat loads associated with power - semiconductor devices, such as IGBTs and MOSFETs, ensuring stable operation and preventing thermal runaway.

The mechanical strength of aluminum base PCBs also makes them suitable for use in industrial environments, where they may be exposed to vibrations, shocks, and temperature fluctuations. Their ability to support high - density component integration allows for the creation of compact and efficient power electronic systems, reducing the overall size and weight of the equipment.

Automotive Electronics

The automotive industry has strict requirements for the reliability and performance of electronic components. Aluminum base PCBs meet these requirements with their combination of thermal management, mechanical strength, and electrical reliability. They are used in various automotive applications, such as engine control units (ECUs), advanced driver - assistance systems (ADAS), and automotive lighting.

In ECUs, aluminum base PCBs help to manage the heat generated by the microprocessors and other components, ensuring stable operation even in the harsh under - hood environment. In ADAS systems, which rely on high - performance sensors and processors, these PCBs provide the necessary thermal and electrical support for reliable operation. In automotive lighting, they enable the integration of high - power LEDs in a compact and reliable manner.

Aerospace and Defense

In aerospace and defense applications, where weight, reliability, and performance are of utmost importance, aluminum base PCBs have found widespread use. Their lightweight nature helps to reduce the overall weight of aircraft and spacecraft, improving fuel efficiency and performance. At the same time, their high thermal conductivity and mechanical strength ensure reliable operation in extreme environments, including high altitudes, high temperatures, and high levels of radiation.

Aluminum base PCBs are used in avionics systems, communication equipment, and military electronics. They can withstand the vibrations and shocks experienced during flight and operation, providing a stable platform for the electronic components. Their ability to support high - density integration also allows for the miniaturization of electronic systems, which is essential in aerospace and defense applications where space is at a premium.

Consumer Electronics

Consumer electronics, such as laptops, tablets, smartphones, and gaming consoles, are constantly evolving to become smaller, more powerful, and more energy - efficient. Aluminum base PCBs play a crucial role in this evolution by providing efficient thermal management and supporting high - density component integration.

In laptops and tablets, these PCBs help to manage the heat generated by the processors and other components, ensuring stable performance and preventing overheating. In smartphones and gaming consoles, their ability to support compact designs and high - speed signal transmission is essential. The mechanical strength of aluminum base PCBs also provides protection for the components, making the devices more durable.

Emerging Trends and Future Outlook

Integration with Smart Technologies

As the Internet of Things (IoT) and smart technologies continue to gain momentum, aluminum base PCBs are expected to play an even more important role. They will be integrated with sensors, microcontrollers, and wireless communication modules to create smart and connected electronic devices. These devices will be able to collect and transmit data, enabling remote monitoring and control.

In smart homes, for example, aluminum base PCBs could be used in smart lighting systems, smart thermostats, and security systems. In industrial applications, they will be used in smart factories to enable real - time monitoring and control of production processes. The integration of these technologies with aluminum base PCBs will require new design and manufacturing techniques to ensure reliable operation and efficient performance.

Miniaturization and High - Density Integration

The trend towards miniaturization in electronics is driving the development of smaller and more densely populated PCBs. Aluminum base PCBs are no exception. Advanced manufacturing techniques, such as micro - via technology and fine - pitch trace routing, are being used to create PCBs with higher component densities while maintaining optimal performance.

This miniaturization trend is particularly evident in wearable electronics, medical implants, and other portable devices. Aluminum base PCBs with high - density integration capabilities will enable the creation of smaller, more powerful, and more energy - efficient devices. However, this also poses challenges in terms of thermal management and signal integrity, which will require innovative design solutions.

Sustainable Manufacturing Practices

With growing environmental concerns, the electronics industry is increasingly focusing on sustainable manufacturing practices. Aluminum base PCB manufacturers are exploring ways to use recycled materials, reduce energy consumption during production, and minimize waste generation.

Recycled aluminum can be used to produce the aluminum substrate, reducing the demand for virgin materials. Energy - efficient manufacturing processes, such as using renewable energy sources and optimizing production equipment, can help to reduce the carbon footprint of PCB manufacturing. Additionally, efforts are being made to develop more recyclable PCB materials and processes, making the entire lifecycle of aluminum base PCBs more environmentally friendly.

Advanced Thermal Management Solutions

As electronic components become more powerful and generate more heat, there is a growing need for advanced thermal management solutions in aluminum base PCBs. New materials and technologies, such as phase - change materials, heat pipes, and liquid cooling systems, are being integrated with aluminum base PCBs to handle higher heat loads.

Phase - change materials can absorb and store heat, providing passive thermal management. Heat pipes and liquid cooling systems can transfer heat more efficiently away from the components, enabling higher power densities and better performance. These advanced thermal management solutions will be essential for the development of future - generation electronic devices, such as high - performance computing systems and next - generation data centers.

Conclusion

Aluminum base PCBs have emerged as a revolutionary technology in the field of electronics, offering a unique combination of thermal management, mechanical strength, and electrical reliability. Their applications span a wide range of industries, from LED lighting and power electronics to automotive, aerospace, and consumer electronics. As technology continues to evolve, these PCBs will play an even more crucial role in the development of future - proof electronic devices.

By staying at the forefront of material science, design innovation, and manufacturing excellence, the industry can fully leverage the potential of aluminum base PCBs to create innovative, reliable, and high - performance electronic solutions that meet the ever - growing demands of the modern world. The future of aluminum base PCBs looks bright, with continued advancements expected to drive further innovation and growth in the electronics industry.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB