-

- PCB TYPE

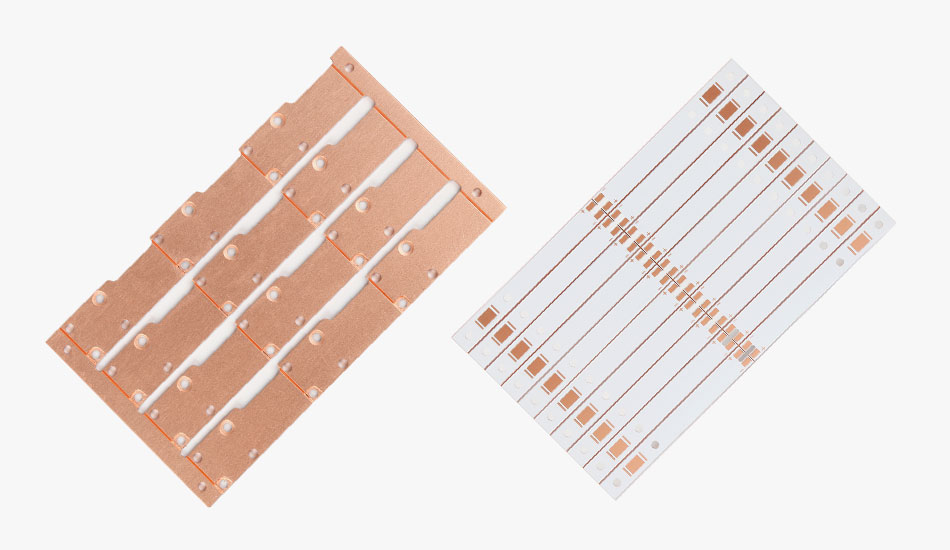

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 06. 2025, 10:32:29

In the dynamic realm of electronics, the relentless pursuit of higher performance, miniaturization, and energy efficiency has led to a burgeoning demand for advanced Printed Circuit Board (PCB) solutions. Among these, Aluminum Core PCBs have emerged as a game - changing technology, offering a unique blend of thermal, mechanical, and electrical properties tailored to the stringent requirements of modern electronic applications.

As electronics continue to permeate every aspect of our lives, from consumer devices to industrial machinery and automotive systems, the need for efficient heat dissipation has become more critical than ever. Traditional PCB materials, such as fiberglass - reinforced epoxy (FR - 4), often struggle to cope with the increasing power densities generated by today's high - performance components. Aluminum Core PCBs, on the other hand, leverage the remarkable thermal conductivity of aluminum to provide an effective solution to this long - standing challenge.

This article delves into the world of Aluminum Core PCBs, exploring their structure, material composition, manufacturing process, applications, design considerations, and advantages over traditional PCBs. By understanding the intricacies of this innovative technology, engineers, designers, and electronics enthusiasts can unlock its full potential and drive the next wave of advancements in the electronics industry.

Structure and Material Composition

Aluminum Core Layer

The defining feature of an Aluminum Core PCB is its aluminum base layer, which serves as the cornerstone of its thermal management capabilities. Aluminum is chosen for its exceptional thermal conductivity, which allows it to rapidly absorb and distribute heat generated by components mounted on the PCB. This is particularly crucial in applications where high - power components, such as power transistors, LEDs, and microprocessors, generate substantial amounts of heat that, if not properly managed, can lead to performance degradation, reduced lifespan, and even system failures.

In addition to its thermal prowess, aluminum also offers excellent mechanical properties. It provides a rigid and stable foundation for the PCB, protecting the delicate circuit traces and components from mechanical stress, vibrations, and shocks. This is especially important in automotive, aerospace, and industrial applications, where PCBs are often subjected to harsh operating conditions.

Furthermore, aluminum is a lightweight material, making it an ideal choice for applications where weight reduction is a priority, such as in portable electronics and electric vehicles. By reducing the weight of the PCB, designers can contribute to overall system weight savings, which in turn can improve energy efficiency and performance.

Dielectric Layer

Sandwiched between the aluminum core and the copper circuit layer, the dielectric layer plays a pivotal role in the functionality of an Aluminum Core PCB. Its primary function is to provide electrical insulation between the conductive aluminum core and the copper traces, preventing short - circuits and ensuring the integrity of the electrical signals.

However, the dielectric layer in an Aluminum Core PCB is not just an insulator; it also serves as a thermal conductor. Specialized dielectric materials, such as ceramic - filled epoxies or polyimide composites, are used to balance the requirements of electrical insulation and thermal conductivity. These materials are carefully engineered to have a high thermal conductivity, allowing heat to flow efficiently from the copper circuit layer to the aluminum core.

The thickness and composition of the dielectric layer are critical design parameters that significantly impact the thermal and electrical performance of the PCB. A thinner dielectric layer generally offers better thermal conductivity but may compromise electrical insulation, while a thicker layer provides enhanced electrical protection at the expense of thermal performance. Designers must carefully optimize these parameters to meet the specific requirements of each application.

Copper Circuit Layer

The copper circuit layer is where the electrical pathways are etched onto the PCB. Copper is widely used in PCBs due to its excellent electrical conductivity, which minimizes signal loss and power dissipation. In an Aluminum Core PCB, high - purity copper is typically employed to ensure optimal electrical performance.

The copper traces are designed to carry electrical current to and from the various components mounted on the PCB, enabling the flow of power and signals. The width and thickness of the copper traces are carefully determined based on the current - carrying requirements of the components, as well as considerations for signal integrity and electromagnetic interference (EMI) reduction.

To enhance the reliability and durability of the copper circuit layer, surface finishing processes are often applied. Common surface finishes include electroless nickel immersion gold (ENIG), immersion tin, and organic solderability preservative (OSP). These finishes protect the copper from oxidation and corrosion, improve solderability, and provide a smooth and reliable surface for component mounting.

Manufacturing Process

Material Preparation

The manufacturing process of an Aluminum Core PCB begins with the careful selection and preparation of high - quality materials. The aluminum core is sourced from reputable suppliers and undergoes thorough inspection to ensure its purity, flatness, and freedom from defects. It is then cleaned and treated to remove any contaminants or oxides from its surface, preparing it for the subsequent lamination process.

The dielectric material, typically in the form of a pre - impregnated film or a liquid resin, is also carefully selected based on its thermal and electrical properties. It is cut to the appropriate size and shape to match the dimensions of the aluminum core.

The copper foil, which will form the circuit layer, is inspected for thickness uniformity and freedom from scratches or other defects. It is then prepared for lamination by applying a thin layer of adhesive to one side.

Lamination

The lamination process is a critical step in the manufacturing of an Aluminum Core PCB, as it determines the integrity and performance of the final product. During lamination, the dielectric layer is placed between the aluminum core and the copper foil, and the three layers are pressed together under high pressure and temperature.

The pressure and temperature conditions are carefully controlled to ensure a uniform and void - free bond between the layers. This is essential for maintaining good thermal and electrical conductivity, as well as mechanical strength. The lamination process may be carried out using a variety of techniques, such as hot - press lamination, vacuum lamination, or a combination of both.

Circuit Pattern Formation

Once the lamination process is complete, the next step is to create the circuit pattern on the copper layer. This is typically done using a photolithography process, which involves applying a photosensitive resist material to the surface of the copper foil.

The resist is then exposed to ultraviolet (UV) light through a mask that contains the desired circuit pattern. The UV light causes a chemical reaction in the resist, making it soluble in a developer solution. The unexposed areas of the resist are then removed by immersion in the developer, leaving behind the circuit pattern.

The exposed copper areas are then etched away using a chemical etchant, leaving behind the copper traces that form the electrical pathways of the PCB. The etching process is carefully controlled to ensure accurate trace widths and spacing, as well as clean and sharp edges.

Drilling and Plating

After the circuit pattern has been formed, holes are drilled through the PCB for component mounting, vias, and electrical connections. The drilling process is typically carried out using a high - speed drill press with specialized drill bits designed for use with PCB materials.

Once the holes have been drilled, they are plated with copper to create conductive pathways between the different layers of the PCB. The plating process may involve electroless copper plating, followed by electroplating to increase the thickness of the copper layer. The plating process is carefully controlled to ensure uniform and reliable electrical connections.

Surface Finishing

The final step in the manufacturing process of an Aluminum Core PCB is surface finishing. As mentioned earlier, surface finishing processes are applied to the copper circuit layer to protect it from oxidation and corrosion, improve solderability, and provide a smooth and reliable surface for component mounting.

Common surface finishing options include ENIG, immersion tin, OSP, and hot - air solder leveling (HASL). Each surface finish has its own advantages and disadvantages, and the choice of finish depends on the specific requirements of the application, such as cost, reliability, and environmental considerations.

Quality Control

Throughout the manufacturing process, strict quality control measures are implemented to ensure that the Aluminum Core PCBs meet the highest standards of quality and performance. This includes visual inspection, electrical testing, thermal testing, and mechanical testing.

Visual inspection is used to check for any visible defects, such as scratches, voids, or misaligned layers. Electrical testing is performed to verify the integrity of the electrical connections, including continuity, insulation resistance, and impedance. Thermal testing is carried out to ensure that the PCB can effectively dissipate heat and maintain safe operating temperatures. Mechanical testing is used to evaluate the mechanical strength and durability of the PCB, including its resistance to bending, vibration, and shock.

Any PCBs that do not meet the quality standards are rejected, and the manufacturing process is adjusted to correct the issues. This rigorous quality control process helps to ensure that only high - quality Aluminum Core PCBs are delivered to customers.

Applications in Diverse Industries

LED Lighting

One of the most widespread applications of Aluminum Core PCBs is in the field of LED lighting. LEDs are highly efficient light sources, but they generate a significant amount of heat during operation. If this heat is not effectively dissipated, it can lead to a decrease in the luminous efficiency, color shift, and reduced lifespan of the LEDs.

Aluminum Core PCBs provide an ideal solution for LED lighting applications, as their high thermal conductivity allows for efficient heat dissipation from the LEDs. This helps to maintain the operating temperature of the LEDs within an optimal range, ensuring consistent and reliable performance. Additionally, the lightweight and compact nature of Aluminum Core PCBs make them well - suited for use in a variety of LED lighting fixtures, from small household bulbs to large - scale commercial and industrial lighting systems.

Power Electronics

In power electronics applications, such as power supplies, inverters, and motor control units, Aluminum Core PCBs play a crucial role in managing the high power densities and heat generation associated with these systems. Power semiconductor devices, such as MOSFETs, IGBTs, and diodes, generate substantial heat during operation, and effective thermal management is essential to prevent thermal runaway and ensure reliable operation.

Aluminum Core PCBs offer excellent thermal conductivity, allowing for efficient heat transfer from the power components to the aluminum core, which can then dissipate the heat into the surrounding environment. This helps to reduce the operating temperature of the power components, improve their efficiency, and extend their lifespan. Furthermore, the mechanical strength and stability of Aluminum Core PCBs make them suitable for use in applications where the PCB may be subjected to vibrations, shocks, and other mechanical stresses.

Automotive Electronics

The automotive industry is another major consumer of Aluminum Core PCBs, as they are used in a wide range of automotive electronics applications. From engine control units (ECUs) and advanced driver - assistance systems (ADAS) to lighting and infotainment systems, Aluminum Core PCBs provide the necessary thermal management, electrical reliability, and mechanical durability required in automotive environments.

In automotive applications, PCBs are often exposed to harsh conditions, including high temperatures, vibrations, and electromagnetic interference. Aluminum Core PCBs are well - equipped to handle these challenges, thanks to their high thermal conductivity, which helps to dissipate heat generated by components in the engine compartment and other high - temperature areas. The mechanical strength of the aluminum core also provides resistance to vibrations and shocks, ensuring the long - term reliability of the PCB. Additionally, the aluminum core can act as a shield against electromagnetic interference, helping to protect sensitive electronic components from external electrical noise.

Consumer Electronics

In the world of consumer electronics, where sleek designs, high performance, and long battery life are highly valued, Aluminum Core PCBs are increasingly being used to meet the demands of modern devices. In smartphones, tablets, laptops, and gaming consoles, for example, Aluminum Core PCBs help to manage the heat generated by high - performance processors, graphics cards, and other components.

By efficiently dissipating heat, Aluminum Core PCBs enable these devices to operate at higher clock speeds and with greater stability, resulting in improved performance. Moreover, the lightweight and compact nature of Aluminum Core PCBs allows for more space - efficient designs, contributing to the overall sleekness and portability of consumer electronics. Additionally, the improved thermal management provided by Aluminum Core PCBs can help to extend the battery life of these devices, as components operating at lower temperatures consume less power.

Aerospace and Defense

The aerospace and defense industries have some of the most demanding requirements for electronic components, including high reliability, resistance to extreme environmental conditions, and lightweight designs. Aluminum Core PCBs are well - suited to meet these requirements, making them a popular choice in a variety of aerospace and defense applications.

In avionics systems, such as flight control computers, navigation systems, and communication equipment, Aluminum Core PCBs provide the necessary thermal management and mechanical stability to ensure reliable operation in the harsh environment of an aircraft. The high thermal conductivity of the aluminum core helps to dissipate heat generated by components, preventing overheating and ensuring optimal performance. The mechanical strength of the aluminum core also provides resistance to vibrations, shocks, and other mechanical stresses experienced during flight.

In defense applications, such as military vehicles, radar systems, and missile guidance systems, Aluminum Core PCBs are used to provide reliable and durable electronic solutions. The ability of Aluminum Core PCBs to withstand extreme temperatures, humidity, and electromagnetic interference makes them ideal for use in these demanding environments. Additionally, the lightweight nature of Aluminum Core PCBs helps to reduce the overall weight of military equipment, which can be crucial for mobility and fuel efficiency.

Design Considerations

Thermal Design

Thermal design is of utmost importance when designing an Aluminum Core PCB, as its primary function is to manage heat. Designers must carefully consider the placement of heat - generating components on the PCB to ensure that they are in close proximity to the aluminum core for efficient heat transfer. Thermal vias, which are small holes filled with a thermally conductive material, can be used to enhance heat flow from the copper circuit layer to the aluminum core.

The layout of the PCB should also be optimized to allow for proper airflow around the components, as natural or forced convection can further aid in heat dissipation. Additionally, designers may need to consider the use of additional cooling mechanisms, such as heat sinks or fans, in applications where the heat load is particularly high.

Mechanical Design

Mechanical design considerations are also crucial when working with Aluminum Core PCBs, especially in applications where the PCB may be subjected to mechanical stress, vibrations, or shocks. The aluminum core provides a rigid and stable base for the PCB, but additional measures may be needed to ensure its long - term mechanical integrity.

This may include using appropriate mounting techniques, such as through - hole mounting or surface - mount technology, to securely attach the PCB to the enclosure or other components. Reinforced mounting holes or standoffs can be used to distribute mechanical stress evenly and prevent damage to the PCB. Additionally, designers may need to consider the effects of thermal expansion and contraction on the PCB, as different materials in the PCB stack - up may have different coefficients of thermal expansion.

Electrical Design

In addition to thermal and mechanical design, electrical design considerations are also important when designing an Aluminum Core PCB. The copper circuit layer must be designed to carry the required electrical current while minimizing signal loss and electromagnetic interference. This may involve using appropriate trace widths and spacing, as well as implementing proper grounding and shielding techniques.

The dielectric layer between the aluminum core and the copper circuit layer must also be carefully selected to ensure proper electrical insulation. The dielectric constant and dissipation factor of the dielectric material can affect the electrical performance of the PCB, especially in high - frequency applications. Designers may need to perform simulations and measurements to optimize the electrical performance of the PCB and ensure that it meets the requirements of the application.

Compatibility with Components

When designing an Aluminum Core PCB, it is important to ensure compatibility with the components that will be mounted on the board. This includes considering the mechanical dimensions, electrical characteristics, and thermal requirements of the components. For example, some components may require a specific footprint or mounting pattern on the PCB, while others may have specific voltage or current requirements.

It is also important to consider the thermal interface between the components and the PCB. Some components may require the use of thermal pads or adhesives to ensure efficient heat transfer to the aluminum core. Additionally, designers may need to consider the compatibility of the components with the surface finish of the PCB, as some surface finishes may affect the solderability or corrosion resistance of the components.

Advantages Over Traditional PCBs

Superior Thermal Performance

One of the most significant advantages of Aluminum Core PCBs over traditional PCBs, such as those made from FR - 4 material, is their superior thermal performance. The high thermal conductivity of the aluminum core allows for much more efficient heat dissipation, which can significantly reduce the operating temperature of components mounted on the PCB.

This is particularly important in applications where high - power components generate a large amount of heat, as excessive heat can lead to performance degradation, reduced lifespan, and even component failure. By effectively managing heat, Aluminum Core PCBs can improve the reliability and performance of electronic systems, and may even eliminate the need for additional cooling mechanisms in some cases.

Improved Mechanical Strength

Aluminum Core PCBs also offer improved mechanical strength compared to traditional PCBs. The aluminum core provides a rigid and stable base for the PCB, which can help to protect the delicate circuit traces and components from mechanical stress, vibrations, and shocks.

This is especially important in applications where the PCB may be subjected to harsh operating conditions, such as in automotive, aerospace, and industrial environments. The improved mechanical strength of Aluminum Core PCBs can help to ensure the long - term reliability of the PCB and the electronic system as a whole.

Lightweight Design

Another advantage of Aluminum Core PCBs is their lightweight design. Aluminum is a relatively lightweight material compared to other metals, such as copper or steel, which are sometimes used in PCBs. This can be particularly beneficial in applications where weight reduction is a priority, such as in portable electronics, electric vehicles, and aerospace applications.

By reducing the weight of the PCB, designers can contribute to overall system weight savings, which in turn can improve energy efficiency, performance, and range. Additionally, the lightweight nature of Aluminum Core PCBs can make them easier to handle and install, reducing the complexity and cost of the manufacturing and assembly process.

Cost - Effectiveness

While Aluminum Core PCBs may have a higher upfront cost compared to some traditional PCBs, they can offer significant cost - effectiveness in the long run. Their superior thermal performance can help to reduce the need for additional cooling mechanisms, such as heat sinks or fans, which can add to the cost and complexity of the electronic system.

Furthermore, the improved reliability and lifespan of components mounted on Aluminum Core PCBs can result in fewer component failures and replacements, reducing maintenance costs over time. Additionally, the lightweight design of Aluminum Core PCBs can contribute to overall system cost savings by reducing the weight of other components, such as enclosures and mounting hardware.

Future Trends and Innovations

Advanced Materials and Manufacturing Techniques

As the demand for even more efficient and high - performance Aluminum Core PCBs continues to grow, researchers and manufacturers are exploring the use of advanced materials and manufacturing techniques. This includes the development of new dielectric materials with even higher thermal conductivity, such as graphene - enhanced composites or diamond - filled epoxies, which could further reduce thermal resistance and improve heat dissipation.

In manufacturing, additive manufacturing (3D printing) is being tested to create complex internal structures, such as embedded heat pipes or micro - channels within the aluminum core, to enhance heat flow in three dimensions. These innovations could enable more compact and efficient thermal management solutions for next - generation electronics.

Integration with Emerging Technologies

Aluminum Core PCBs are poised to play a key role in emerging technologies such as autonomous vehicles, 5G infrastructure, and high - performance computing. In autonomous vehicles, where multiple high - power sensors and processors must operate reliably in tight spaces, Aluminum Core PCBs will be essential for managing heat in LiDAR systems, advanced ECUs, and battery management units.

In 5G base stations, the high - frequency components and power amplifiers require PCBs with excellent thermal and electrical properties. Aluminum Core PCBs can support the miniaturization of these systems while ensuring reliable heat dissipation, which is critical for maintaining signal integrity and reducing downtime.

Sustainable and Eco - Friendly Solutions

With increasing environmental awareness, the industry is moving toward more sustainable practices. Aluminum, a highly recyclable material, already offers an eco - friendly advantage over non - metal cores. Future developments will focus on using recycled aluminum for cores and bio - based dielectric materials, as well as implementing lead - free and low - VOC (volatile organic compound) manufacturing processes. These initiatives align with global sustainability goals and will make Aluminum Core PCBs even more attractive for environmentally conscious industries.

Miniaturization and Multilayer Designs

As electronics continue to shrink, Aluminum Core PCBs are evolving to support multilayer configurations and finer trace geometries. Multilayer Aluminum Core PCBs will allow for more complex circuit routing while maintaining thermal efficiency, making them suitable for high - density applications such as medical devices and aerospace avionics. Advanced lamination techniques and thinner dielectric layers will enable these compact designs without compromising on thermal or mechanical performance.

Conclusion

Aluminum Core PCBs have emerged as a transformative technology in the electronics industry, addressing the critical challenge of thermal management while offering mechanical robustness and electrical reliability. Their unique combination of aluminum's thermal conductivity, lightweight design, and advanced material science has made them indispensable in applications ranging from LED lighting and automotive electronics to aerospace and industrial systems.

As technology continues to advance, Aluminum Core PCBs will only become more integral to the development of high - performance, energy - efficient devices. With ongoing innovations in materials, manufacturing, and sustainability, these PCBs are set to drive the next generation of electronics, enabling smaller, smarter, and more reliable systems across all sectors. For engineers and designers, embracing Aluminum Core PCB technology is not just a choice—it's a necessity for staying ahead in a rapidly evolving industry.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB