-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 14. 2025, 10:42:38

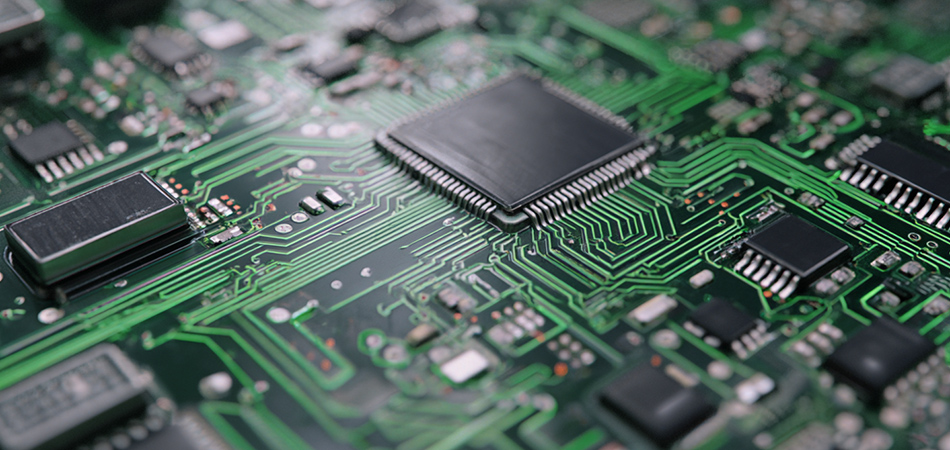

In the intricate ecosystem of modern electronics, the aluminum PCB stackup serves as a critical architectural framework, balancing thermal efficiency, electrical performance, and mechanical stability. Unlike traditional PCB stackups reliant on non-metallic cores, aluminum-based configurations leverage the unique properties of aluminum to address the demands of high-power, high-density devices. This article explores the foundational structure, design principles, material interactions, manufacturing considerations, and diverse applications of aluminum PCB stackups, providing a comprehensive guide to their role in advancing electronic systems.

Defining Aluminum PCB Stackup: Structure and Purpose

Core Architectural Components

An aluminum PCB stackup is a layered composite designed to integrate electrical conduction, thermal management, and mechanical support:

Aluminum Substrate: The foundational layer, typically an alloyed aluminum sheet, providing thermal dissipation and structural rigidity. Its thickness and alloy composition are selected based on thermal load and mechanical requirements.

Dielectric Layer: A thin insulating material bonding the aluminum substrate to conductive copper layers. This layer ensures electrical isolation while facilitating heat transfer from copper traces to the aluminum core.

Copper Conductive Layers: Thin copper foils (single or multiple) patterned into traces for signal transmission and power distribution. These layers may include signal, power, or ground planes, depending on the stackup complexity.

This structure creates a synergistic system where each layer complements the others: the aluminum substrate manages heat, the dielectric maintains insulation, and copper enables electrical functionality.

Key Functions in Electronic Systems

Thermal Pathway Creation: The stackup’s layered design establishes low-resistance routes for heat to flow from heat-generating components (e.g., power transistors) through copper traces and dielectric layers to the aluminum substrate, where it is dissipated.

Electrical Signal Integrity: Properly configured copper layers and dielectric materials minimize signal loss, crosstalk, and electromagnetic interference (EMI), critical for high-frequency applications like 5G base stations.

Mechanical Stability: The aluminum core resists warping under thermal cycling, ensuring dimensional consistency for solder joints and component alignment—essential in vibration-prone environments such as automotive electronics.

Stackup Configuration: From Simple to Complex

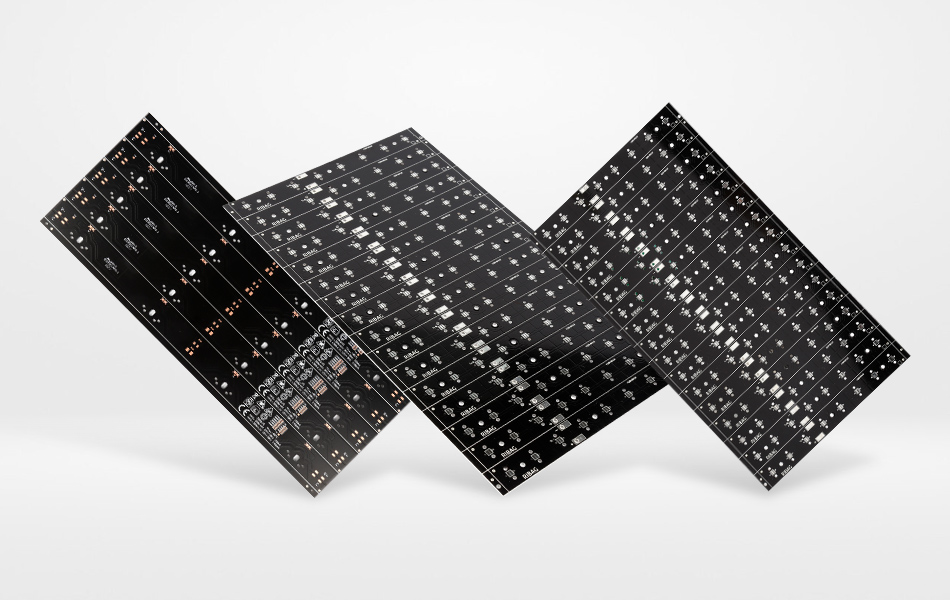

Basic 2-Layer Stackup

The simplest aluminum PCB stackup features two functional layers:

Top Copper Layer: Hosts surface-mount components and signal/power traces, directly bonded to the dielectric layer.

Aluminum Substrate + Dielectric: A single dielectric layer bonds the top copper to the aluminum core, which serves as both heat sink and structural base.

This configuration is common in low-power applications such as LED lighting and small consumer electronics, where thermal demands are moderate and cost efficiency is prioritized. Its simplicity allows for easy manufacturing and rapid prototyping.

Multi-Layer Stackups (4-Layer and Beyond)

For complex systems requiring enhanced functionality, multi-layer stackups incorporate additional layers:

Inner Signal/Power Layers: Added between the top copper and dielectric, enabling separation of analog/digital signals or dedicated power distribution. These layers reduce crosstalk in high-speed circuits (e.g., microprocessors in industrial controllers).

Dual-Sided Copper Layers: Some stackups feature copper on both sides of the aluminum core (with dielectric layers), supporting denser component placement and bidirectional heat dissipation—ideal for power inverters and automotive radar modules.

Multi-layer configurations leverage vertical integration to maximize board real estate, accommodating miniaturization without sacrificing performance.

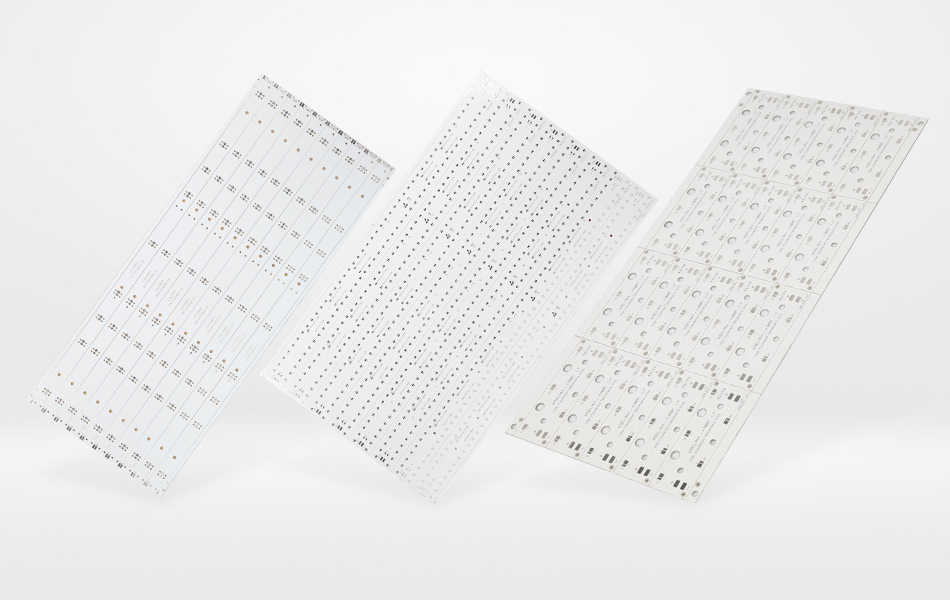

Hybrid Stackup Variations

Innovative designs blend aluminum cores with flexible or specialized layers:

Flex-Rigid Combinations: Integrating flexible dielectric segments (e.g., polyimide) with rigid aluminum sections enables bendable regions, useful in wearable devices or curved automotive displays.

Embedded Heat Spreader Layers: Thin graphite or copper-infiltrated layers within the stackup enhance lateral heat spread, critical for unevenly distributed thermal loads (e.g., LED arrays with varying power densities).

Material Interactions in Aluminum PCB Stackup

Aluminum Substrate: Alloy and Properties

The aluminum substrate’s performance is governed by its material characteristics:

Alloy Selection: 6xxx series alloys (e.g., 6061) balance thermal conductivity and mechanical strength, suitable for general-purpose applications. 5xxx series alloys (e.g., 5052) offer superior corrosion resistance, ideal for marine or humid environments.

Surface Treatment: Chemical etching or anodization enhances adhesion with the dielectric layer, preventing delamination. Anodized surfaces also provide a thin insulating barrier, useful in high-voltage applications.

Thermal Conductivity: The substrate’s ability to transfer heat is a primary selection criterion—higher conductivity alloys (e.g., 1xxx series) are preferred for heat-intensive devices like power amplifiers.

Dielectric Layer: Balancing Insulation and Heat Transfer

Dielectric materials are chosen to optimize two conflicting needs: electrical isolation and thermal conduction:

Ceramic-Filled Epoxies: Cost-effective options with moderate thermal conductivity (~1–3 W/mK), suitable for consumer electronics and LED lighting.

Polyimides: High-temperature resistant (up to 260°C) with low dielectric loss, ideal for aerospace and automotive under-hood electronics.

PTFE Composites: Offer ultra-low dielectric constant (Dk) and loss, enabling high-frequency performance in radar and 5G applications, though with lower thermal conductivity than ceramic-based alternatives.

The dielectric’s thickness directly impacts thermal resistance—thinner layers facilitate better heat transfer but require higher dielectric strength to prevent breakdown.

Copper Layers: Conductivity and Configuration

Copper layers in the stackup are engineered for electrical performance:

Foil Type: Electrolytic copper provides cost-effective conductivity for power layers, while rolled copper, with its smoother surface, minimizes signal loss in high-frequency traces.

Thickness Variation: Thicker copper (e.g., 2–3oz) reduces resistance in power distribution paths, critical for high-current applications like motor drives. Thinner copper (0.5–1oz) enables finer trace pitches in dense digital circuits.

Surface Finishes: ENIG (Electroless Nickel Immersion Gold) enhances solderability and corrosion resistance, while OSP (Organic Solderability Preservative) is preferred for cost-sensitive, low-temperature applications.

Design Principles for Effective Stackup Engineering

Thermal Management in Layer Design

Vertical Heat Path Optimization: Thermal vias—plated holes connecting copper layers to the aluminum substrate—create direct pathways for heat to bypass the dielectric layer. Strategic placement beneath heat sources (e.g., MOSFETs) minimizes thermal resistance.

Layer Symmetry: Balanced copper distribution on both sides of the aluminum core reduces warping during thermal cycling, a critical consideration for large-format PCBs in industrial equipment.

Dielectric-Core Compatibility: Matching the dielectric’s coefficient of thermal expansion (CTE) to the aluminum substrate reduces interfacial stress, preventing delamination in temperature-fluctuating environments.

Electrical Performance Considerations

Impedance Control: Trace width, dielectric thickness, and copper weight are tuned to achieve target impedance (e.g., 50Ω for RF traces), ensuring signal integrity in high-speed systems.

Ground Plane Design: A solid ground plane adjacent to signal layers reduces EMI by providing a low-impedance return path and shielding against external interference. In multi-layer stackups, ground planes are often placed between signal layers to isolate analog and digital domains.

Power Distribution: Dedicated power planes minimize voltage drops across the board, ensuring stable supply to components. These planes are connected to the aluminum substrate via thermal vias to dissipate any residual heat from conduction losses.

Mechanical Design for Durability

Stackup Thickness: Total thickness is optimized to withstand application-specific mechanical stresses—thicker stacks for structural support in industrial machinery, thinner stacks for portable devices.

Edge Reinforcement: Reinforced edges or stiffeners prevent flexing in large stackups, protecting solder joints and via connections in vibration-prone settings (e.g., railway electronics).

Form Factor Adaptation: Curved or contoured stackups, achieved by shaping the aluminum core before lamination, enable integration into non-planar enclosures like automotive dashboards.

Manufacturing Processes for Aluminum PCB Stackup

Layer Preparation and Lamination

Substrate Preparation: Aluminum sheets are cut to size, degreased, and etched to remove oxides, ensuring strong adhesion with the dielectric layer.

Dielectric Application: The dielectric material is applied as a pre-preg sheet or liquid resin, then laminated to the aluminum substrate under controlled heat and pressure (typically 150–200°C and 10–30 MPa) to eliminate air bubbles.

Copper Bonding: Copper foil is laminated to the dielectric layer in a secondary press cycle, with temperature profiles adjusted based on dielectric type (e.g., higher temperatures for polyimides).

Via Formation and Plating

Drilling: Mechanical drilling for through-vias or laser drilling for microvias creates holes connecting layers. Laser drilling is preferred for fine-pitch applications (e.g., 5G modules) due to its precision.

Desmearing and Plating: Via walls are cleaned to remove dielectric residue (desmearing), then plated with copper to establish electrical continuity between layers. Thick plating in power vias enhances current-carrying capacity.

Circuit Patterning and Finishing

Photolithography: Circuit patterns are transferred to copper layers using UV exposure and photoresist development, followed by chemical etching to remove unwanted copper.

Surface Treatment: After etching, copper surfaces are finished with ENIG, OSP, or other coatings to protect against oxidation and ensure solderability.

Testing: Automated optical inspection (AOI) checks for etching defects, while electrical testing verifies continuity and isolation between layers.

Applications Across Industries

Renewable Energy Systems

Solar Inverters: Aluminum stackups with thick copper power layers handle high currents in DC-to-AC conversion, while the aluminum core dissipates heat from IGBTs, ensuring efficiency in outdoor installations.

Wind Turbine Controllers: Multi-layer stackups with embedded ground planes resist EMI from motor noise, maintaining reliable operation in harsh, high-vibration environments.

Communication Infrastructure

5G Base Stations: High-frequency stackups with PTFE dielectrics and thin copper traces minimize signal loss in mmWave transceivers, while aluminum cores manage heat from power amplifiers.

Satellite Communication: Radiation-resistant stackups (using specialized dielectrics) withstand space environments, with aluminum substrates dissipating heat in vacuum conditions.

Industrial Automation

Robotic Control Systems: Hybrid flex-rigid stackups enable motion in robotic arms, with aluminum sections providing thermal management for motor drivers and flexible segments accommodating movement.

Power Distribution Units (PDUs): Thick aluminum cores and high-conductivity dielectrics handle 3-phase power distribution, preventing overheating in factory electrical systems.

Consumer Electronics

Smart Home Devices: Compact 2-layer stackups in smart thermostats balance cost and thermal performance, using aluminum cores to dissipate heat from Wi-Fi modules.

Gaming Hardware: Multi-layer stackups with dedicated power planes for GPUs ensure stable performance, with aluminum substrates managing heat in compact console enclosures.

Emerging Innovations in Aluminum Stackup Technology

Advanced Material Integration

Nano-Composite Dielectrics: Addition of nano-sized ceramic particles (e.g., boron nitride) to epoxy dielectrics boosts thermal conductivity by 50–100% without increasing dielectric loss, enabling thinner stackups in high-power devices.

Graphene-Enhanced Copper: Copper layers infused with graphene exhibit higher conductivity and thermal resilience, useful in high-frequency and high-current applications.

Manufacturing Process Advancements

Laser Direct Structuring (LDS): Enables 3D circuit patterning on curved aluminum substrates, useful for automotive sensors and wearable devices with non-planar form factors.

Automated Lamination Systems: AI-driven pressure and temperature control during lamination ensures uniform dielectric bonding, reducing variability in thermal performance.

Sustainability in Stackup Design

Recycled Aluminum Cores: Use of post-industrial recycled aluminum (with comparable thermal properties to virgin alloys) reduces environmental impact, aligning with automotive and consumer electronics sustainability goals.

Lead-Free Dielectrics: Phthalate-free and halogen-free dielectric materials meet RoHS and REACH standards, improving eco-friendliness without compromising performance.

Conclusion

Aluminum PCB stackup design represents a critical intersection of material science, electrical engineering, and thermal management, enabling the next generation of high-performance electronic devices. By leveraging aluminum’s thermal conductivity, dielectric materials’ insulation properties, and copper’s conduction capabilities, these stackups address the dual challenges of increasing power density and miniaturization. From renewable energy systems to 5G infrastructure, their versatility across industries underscores their importance in modern electronics.

As technology advances, innovations in materials and manufacturing will further enhance stackup performance, enabling even higher frequencies, greater thermal efficiency, and more sustainable designs. For engineers, understanding the fundamentals of aluminum PCB stackup design is essential to unlocking the full potential of electronic systems, ensuring they meet the rigorous demands of today’s and tomorrow’s applications.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB