-

- PCB TYPE

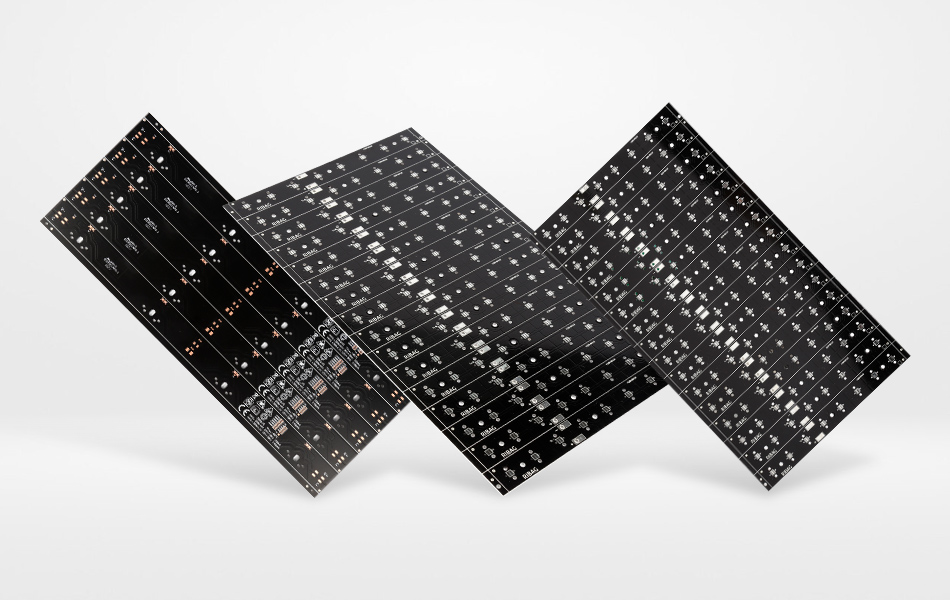

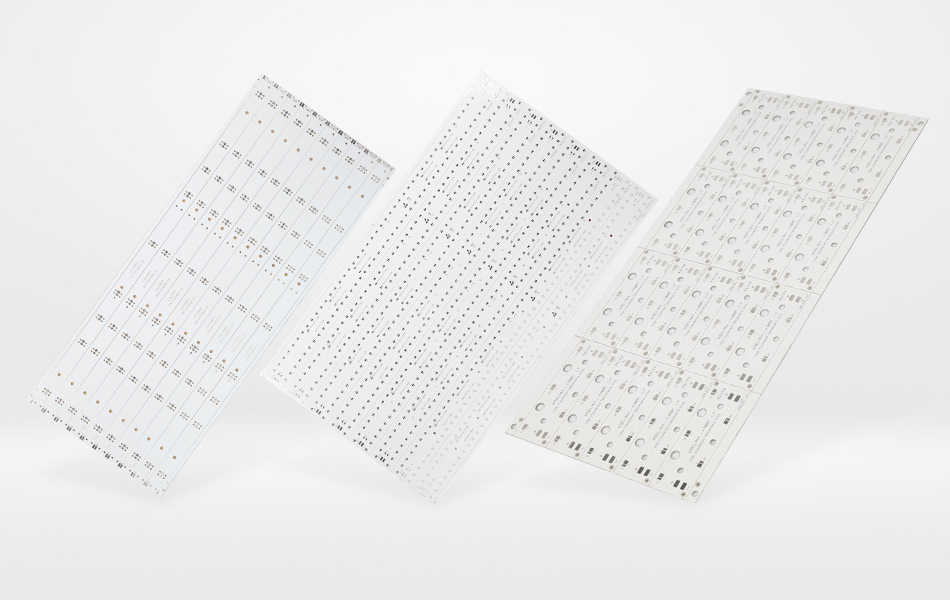

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 16. 2025, 09:45:55

Aluminum PCB structure serves as the backbone of high-performance electronic systems, balancing thermal efficiency, mechanical robustness, and electrical functionality. Unlike traditional FR4 PCBs reliant on non-conductive cores, aluminum-based structures leverage metal substrates to address the growing demands of power-dense devices across industries. This guide explores the fundamental components, material interactions, design principles, and application-specific adaptations of aluminum PCB structures, providing engineers and designers with a framework for optimizing performance through structural excellence.

Core Components of Aluminum PCB Structure

Aluminum Substrate: The Foundation

The aluminum substrate forms the structural and thermal core of the PCB, with its properties directly influencing overall performance:

Alloy Selection: Aluminum alloys are chosen based on application needs—6xxx series alloys offer a balance of thermal conductivity and mechanical strength, ideal for general electronics, while 5xxx series variants provide enhanced corrosion resistance for marine or industrial environments. The alloy’s purity and tempering process determine its ability to dissipate heat and resist warping.

Surface Preparation: Substrate surfaces undergo treatments like etching, anodization, or conversion coating to improve adhesion with dielectric layers. Anodization creates a thin insulating oxide layer, critical for preventing electrical shorting while maintaining thermal pathways.

Form Factor Variability: Aluminum substrates are available in flat sheets, curved profiles, or even flexible thin-gauge formats, enabling structural adaptation to non-planar enclosures in automotive dashboards or wearable devices.

The substrate’s thickness and rigidity are tailored to application requirements, from thin, lightweight cores for portable electronics to thick, rigid substrates for industrial power modules.

Dielectric Layer: The Insulating Mediator

Positioned between the aluminum substrate and conductive copper layers, the dielectric layer is a critical structural component:

Material Classifications: Dielectrics range from ceramic-filled epoxies (for high thermal transfer) to polyimides (for flexibility) and PTFE composites (for high-frequency applications). Each material choice impacts the structure’s thermal resistance, electrical insulation, and mechanical flexibility.

Thickness Considerations: Thinner dielectrics (≤0.1mm) minimize thermal resistance between copper and aluminum, enhancing heat transfer in power devices, while thicker dielectrics (≥0.2mm) provide better electrical isolation for high-voltage applications like power inverters.

Structural Integrity: The dielectric must withstand mechanical stress from thermal cycling and substrate expansion, requiring formulations with high tensile strength and resistance to delamination.

Advanced dielectrics may include reinforcement layers (e.g., glass fabric) to improve dimensional stability in large-format PCBs.

Copper Layers: Conductive Pathways

Copper layers form the electrical backbone of the aluminum PCB structure:

Configuration Options: Single or multi-layer copper configurations support diverse circuit needs—signal layers for data transmission, power layers for current distribution, and ground planes for EMI shielding.

Bonding Mechanisms: Copper is bonded to the dielectric via adhesive lamination or direct metallization, with bonding strength critical to prevent layer separation during thermal or mechanical stress.

Surface Treatments: Copper surfaces may receive finishes like ENIG (Electroless Nickel Immersion Gold) or OSP (Organic Solderability Preservative) to enhance solderability and corrosion resistance, preserving structural integrity over time.

Copper layer design balances conductivity requirements with structural constraints, ensuring traces and planes integrate seamlessly with the overall PCB architecture.

Interlayer Interactions: Ensuring Structural Compatibility

Thermal Expansion Matching

A key structural challenge is aligning the coefficient of thermal expansion (CTE) of aluminum, dielectric, and copper layers:

CTE Compatibility: Mismatched expansion rates during temperature fluctuations cause interfacial stress, risking delamination. Engineers select materials with complementary CTE profiles, often using ceramic fillers in dielectrics to adjust expansion rates toward aluminum’s CTE.

Stress Distribution: Structural designs may incorporate buffer layers or graded materials between dissimilar layers to distribute stress, preventing crack propagation in the dielectric or at bonding interfaces.

This thermal harmony is critical for reliability in automotive under-hood electronics and aerospace systems with extreme temperature swings.

Adhesion and Bond Strength

Strong interlayer bonding is essential for structural integrity:

Adhesive Systems: Thermosetting adhesives or pressure-sensitive films create permanent bonds between layers, with curing processes (heat, UV) optimized to maximize bond strength without damaging sensitive materials.

Surface Activation: Plasma treatment or chemical etching of aluminum and copper surfaces increases surface energy, enhancing adhesive wetting and bond durability in humid or corrosive environments.

Quality Validation: Bond strength is verified through peel tests and thermal cycling, ensuring the structure withstands operational stresses without layer separation.

Signal Integrity in Structural Design

The physical structure of aluminum PCBs directly impacts electrical performance:

Impedance Control: Structural parameters like dielectric thickness and copper trace width determine signal impedance, requiring precise dimensional control to maintain signal integrity in high-frequency applications (e.g., 5G antennas).

EMI Shielding Integration: Multi-layer structures may include dedicated ground planes or aluminum-based shielding layers, leveraging the substrate’s conductive properties to block electromagnetic interference.

Cross-Talk Mitigation: Structural spacing between signal traces and ground planes minimizes capacitive coupling, with dielectric material selection influencing signal isolation effectiveness.

Structural Design Strategies for Performance Optimization

Layer Stacking Configurations

Structural layer arrangements are tailored to application needs:

Symmetric vs. Asymmetric Stacks: Symmetric designs (equal copper weight on both sides of the aluminum core) minimize warping in large PCBs, while asymmetric stacks optimize thermal transfer in devices with uneven heat distribution (e.g., LED arrays).

Hybrid Structures: Integrating flexible dielectric segments with rigid aluminum cores creates bendable regions in the PCB structure, enabling movement in robotic arms or foldable displays without compromising electrical connectivity.

Embedded Components: Advanced structures may embed passive components (resistors, capacitors) within dielectric layers, reducing overall thickness and improving signal paths by shortening conductive traces.

Mechanical Stability Enhancements

Structural design must address mechanical stress factors:

Edge Reinforcement: Thickened dielectric or aluminum borders strengthen PCB edges, preventing cracking in high-vibration environments like industrial machinery or automotive chassis.

Mounting Feature Integration: Structural provisions like screw holes or standoff locations are incorporated during design, ensuring secure attachment to enclosures without introducing stress concentrations.

Flex-Rigid Transitions: In hybrid structures, gradual transitions between flexible and rigid segments distribute stress, preventing fatigue failure in repeatedly bent areas.

Thermal Path Engineering

The aluminum PCB structure is engineered to optimize heat flow:

Thermal Via Integration: Plated through-holes (vias) connect copper heat sources directly to the aluminum substrate, creating low-resistance thermal pathways that bypass the dielectric layer.

Heat Spreader Design: Enlarged copper pads beneath high-power components distribute heat across a larger area, leveraging the aluminum substrate’s thermal mass to dissipate energy.

Conformal Cooling Channels: In advanced structures, micro-channels machined into the aluminum substrate enable liquid cooling integration, enhancing thermal performance in high-density AI servers.

Manufacturing Influences on Structural Integrity

Lamination Processes

Manufacturing techniques directly impact structural quality:

Controlled Pressure Lamination: Uniform pressure application during lamination eliminates voids between layers, ensuring consistent thermal and electrical performance across the PCB structure.

Temperature Profiling: Curing cycles are optimized for dielectric and adhesive materials, balancing bond strength with material integrity to prevent thermal degradation.

Roll-to-Roll Processing: For flexible aluminum PCBs, continuous roll lamination ensures consistent layer bonding in long-length structures used in wearable sensors or flexible displays.

Machining and Forming Constraints

Structural fabrication must account for material limitations:

Cutting and Drilling: Aluminum’s machinability allows precise cutting, but high-speed tools are required to prevent burr formation that could compromise layer adhesion.

Bending and Forming: Thin-gauge aluminum substrates can be cold-formed into curved structures, with radius limits determined by material ductility to avoid cracking or dielectric damage.

Surface Finishing: Post-fabrication treatments like anodization or painting enhance corrosion resistance without altering the PCB’s structural dimensions or layer bonds.

Application-Specific Structural Adaptations

Automotive Electronics

Aluminum PCB structures in vehicles prioritize durability:

Vibration-Resistant Designs: Thick aluminum cores and reinforced solder joints withstand engine vibrations, with dielectric materials formulated to resist automotive fluids and temperature extremes.

Space-Constrained Configurations: Compact, multi-layer structures fit into tight engine compartments, with integrated cooling paths to manage heat from power electronics.

Renewable Energy Systems

Structures for solar and wind applications focus on reliability:

Outdoor-Ready Materials: UV-resistant dielectrics and corrosion-resistant aluminum substrates ensure structural integrity in exposed environments, with thick copper layers supporting high-current distribution.

Large-Format Stability: Rigid aluminum cores prevent warping in oversized PCBs used in solar inverters, maintaining alignment of high-power connectors.

Medical Devices

Structural designs for medical use emphasize precision and biocompatibility:

Miniaturized Structures: Thin aluminum cores and fine-pitch copper traces enable compact PCBs in implantable devices or portable diagnostic equipment.

Biocompatible Materials: Dielectrics and surface finishes meet ISO 10993 standards, ensuring structural components do not trigger adverse biological responses in wearable or implantable applications.

Future Trends in Aluminum PCB Structural Design

Advanced Material Integration

Emerging materials are expanding structural capabilities:

Nano-Reinforced Dielectrics: Graphene or carbon nanotube additives improve dielectric strength and thermal conductivity, enabling thinner, lighter structures with enhanced performance.

Shape-Memory Alloys: Aluminum alloys that recover their shape after deformation could enable self-healing structural features, repairing minor damage from thermal or mechanical stress.

Digital Twin Modeling

Virtual prototyping is revolutionizing structural design:

Finite Element Analysis (FEA): Digital models simulate thermal and mechanical stresses on PCB structures, optimizing layer configurations and material selections before physical prototyping.

AI-Driven Optimization: Machine learning algorithms analyze application requirements to recommend optimal structural parameters, balancing thermal, electrical, and mechanical performance.

Sustainable Structural Innovations

Eco-friendly design practices are reshaping structures:

Recycled Aluminum Integration: Post-industrial aluminum scrap is incorporated into substrates without sacrificing structural integrity, reducing environmental impact.

Bio-Based Dielectrics: Plant-derived polymers in dielectric layers support biodegradable structural components in consumer electronics, aligning with circular economy goals.

Conclusion: The Intersection of Structure and Performance

Aluminum PCB structure design represents a critical convergence of material science, mechanical engineering, and electrical performance. By optimizing the interactions between aluminum substrates, dielectric layers, and copper pathways, engineers create structures that excel in thermal management, mechanical durability, and signal integrity across diverse applications. As electronics continue to evolve toward higher power densities and miniaturization, aluminum PCB structures will remain foundational, adapting through advanced materials and design techniques to meet emerging challenges. Understanding the principles of structural design—from layer compatibility to manufacturing influences—enables the creation of aluminum PCBs that balance form, function, and reliability in the most demanding electronic systems.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB