-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 14. 2025, 15:28:50

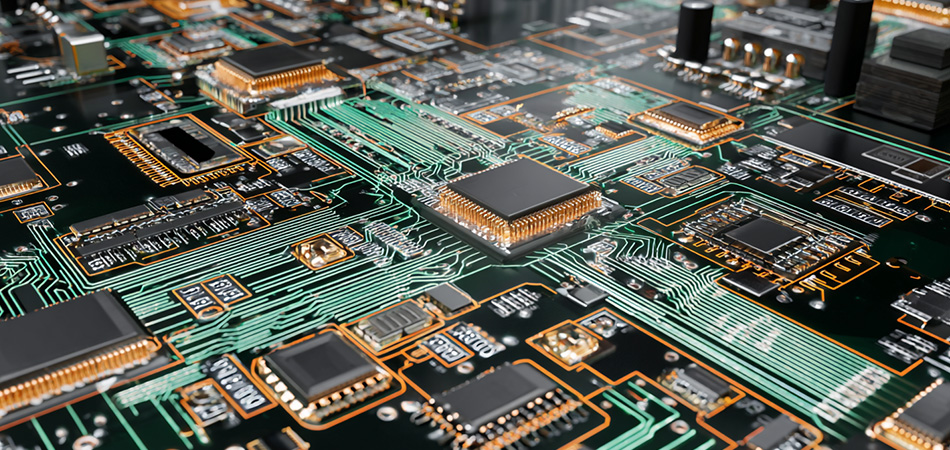

In the automotive industry, where innovation and reliability are paramount, printed circuit boards (PCBs) are crucial for modern vehicle functionality. As automotive systems integrate advanced driver - assistance systems (ADAS), electric powertrains, and in - vehicle infotainment, the demand for PCBs that can withstand harsh conditions has soared. Among them, automotive grade high temp PCBs stand out as vital components, designed to endure extreme temperatures while maintaining peak performance. This article explores their characteristics, design, manufacturing, applications, challenges, and future trends.

Understanding Automotive Grade High Temp PCBs

Definition and Key Characteristics

Automotive grade high temp PCBs are specialized PCBs engineered for reliable operation in high - temperature vehicle environments. Unlike standard PCBs, they resist continuous high - temperature exposure without sacrificing electrical integrity, mechanical stability, or functionality. Their key features include high - temperature resistance, excellent thermal conductivity, and superior mechanical strength. These allow them to function in heat - intense areas like the engine compartment, dissipate heat efficiently, and withstand automotive vibrations and stresses.

Material Selection

Material choice is pivotal for high temp PCBs. Substrate materials like polyphenylene sulfide (PPS), liquid crystal polymer (LCP), and high - temperature FR - 4 variants are commonly used. PPS, with its high melting point and chemical resistance, suits long - term high - temperature applications. LCP offers excellent thermal stability and high - frequency performance, ideal for advanced electronics. High - temperature FR - 4 provides enhanced thermal resistance at a more affordable cost. Specialized copper foils with stable conductivity and adhesion, along with dielectrics maintaining strength and low loss at high temps, are also selected to ensure reliable electrical performance.

Design Considerations for Automotive Grade High Temp PCBs

Thermal Management Design

Thermal management is crucial in high temp PCB design. Strategic use of thermal vias, which transfer heat from components to heat sinks, improves heat transfer. Optimizing component layout by spacing heat - generating parts and promoting air circulation, especially in areas with airflow like the engine compartment, further enhances heat dissipation.

Electrical Design

Electrical design must account for signal integrity, impedance control, and isolation. Selecting materials with stable electrical properties at high temps mitigates signal degradation. Precise trace design, considering width, thickness, spacing, and dielectric properties, controls impedance and ensures reliable signal transmission. Adequate insulation between components and traces, using high - temp insulating materials, prevents short circuits and interference.

Mechanical Design

The mechanical design addresses vehicle - specific harsh conditions. Increasing PCB rigidity with thicker substrates or reinforcements, and using shock - absorbing mounts, helps withstand vibrations. Accounting for material thermal expansion and contraction in component placement prevents mechanical stress and damage to solder joints and the PCB.

Manufacturing Processes for Automotive Grade High Temp PCBs

Lamination

Lamination bonds PCB layers, including substrates, copper foils, and prepregs. High - temperature and pressure techniques are used in high temp PCB manufacturing to create a reliable bond. Precise control is needed to avoid voids, delaminations, and uneven bonding, which can compromise PCB performance in high - temperature environments.

Drilling and Plating

Precision drilling creates holes for vias and component mounting. High - speed machines with advanced controls ensure accurate hole placement. Post - drilling, holes are plated with copper through electroless and electroplating. Special attention is given to ensure good adhesion and integrity of the copper plating at high temperatures.

Circuit Patterning and Etching

Photolithography patterns circuits on copper - clad layers. A photosensitive resist is applied, exposed to UV light through a mask, and developed. Etching then removes unwanted copper. In high temp PCB manufacturing, strict control of the etching process is essential for precise trace widths and clean edges, critical for electrical performance.

Surface Finishing

Surface finishing protects copper surfaces, preventing oxidation and improving solderability. Options like electroless nickel immersion gold (ENIG), organic solderability preservative (OSP), and hot air solder leveling (HASL) are used. ENIG suits high - end applications, OSP is cost - effective, and HASL offers good solderability but has some limitations.

Performance Testing and Quality Control of Automotive Grade High Temp PCBs

Thermal Testing

Thermal tests ensure PCB reliability. High - temperature storage tests expose PCBs to elevated temps for extended periods, checking for physical damage and electrical performance changes. Thermal cycling tests simulate real - world temperature fluctuations, identifying issues related to thermal expansion and contraction.

Electrical Testing

Electrical tests verify PCB functionality. Continuity testing checks for proper connections, insulation resistance testing ensures no electrical leakage, and impedance testing maintains signal integrity, especially for high - frequency applications.

Mechanical Testing

Mechanical tests evaluate PCB strength. Vibration testing simulates vehicle vibrations, shock testing mimics impacts, and bend testing assesses flexibility and strength, ensuring the PCB can withstand installation and operational stresses.

Applications of Automotive Grade High Temp PCBs

Engine Control Units (ECUs)

Located near the engine, ECUs rely on high temp PCBs. These PCBs control engine functions, with their high - temperature resistance and thermal management enabling accurate parameter monitoring and control, even under extreme conditions. They also handle complex sensor data with high - speed signal processing.

Transmission Control Units (TCUs)

TCUs, exposed to high temps and vibrations, use high temp PCBs to control gear shifting and monitor transmission parameters. The reliability of these PCBs is vital for transmission performance, enhancing fuel efficiency and driving comfort.

Advanced Driver - Assistance Systems (ADAS)

ADAS components generate heat, and high temp PCBs connect and control them. With high - temperature resistance and signal integrity, these PCBs ensure reliable data processing, enhancing vehicle safety.

Electric Vehicle (EV) Power Electronics

EV power electronics, such as inverters and battery management systems, produce significant heat. High temp PCBs manage power flow, control battery operations, and ensure drivetrain efficiency. Their thermal conductivity and high - voltage isolation capabilities are crucial for EV safety and reliability.

Challenges and Future Trends of Automotive Grade High Temp PCBs

Challenges

Improving material performance to meet higher temperature and performance demands is a major challenge. Developing new materials with enhanced thermal stability, conductivity, and strength requires ongoing research. Balancing high - performance with cost - effectiveness in manufacturing, despite the use of specialized materials and processes, is also difficult. Ensuring long - term reliability in high - temperature environments, predicting and preventing failures from thermal fatigue and other factors, demands extensive research and testing.

Future Trends

Future high temp PCBs will see increased functionality integration on a single board, driven by the complexity of automotive electronics. This will require advanced technologies like high - density interconnect (HDI) and 3D integration. The use of smart materials and self - monitoring technologies will improve performance and enable proactive maintenance. Additionally, sustainable manufacturing processes, which are energy - efficient and environmentally friendly, will become more prevalent.

Conclusion

Automotive grade high temp PCBs are essential for modern vehicle operation in harsh conditions. Their unique features, careful design, specialized manufacturing, and rigorous testing meet automotive industry demands. Despite challenges, ongoing research promises improvements in materials, processes, and integration. As the automotive industry advances towards sustainability, these PCBs will play a key role in future vehicle electronics.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB