-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 03. 2025, 11:56:25

BGA (Ball Grid Array) Assembly is a foundational surface-mount technology (SMT) that has revolutionized electronic manufacturing by enabling reliable, high-density interconnects between semiconductors and printed circuit boards (PCBs). Unlike traditional leaded packages, BGA uses an array of solder balls on the bottom of the chip to establish electrical connections, offering superior thermal performance, signal integrity, and space efficiency. From consumer gadgets to industrial machinery, BGA assembly has become a staple in electronics production, adapting to evolving demands for smaller, faster, and more reliable devices. This article explores the core fundamentals of BGA assembly, its diverse industry applications, common challenges, and modern strategies to optimize process efficiency and quality.

BGA assembly involves a sequence of precision-driven steps, each critical to ensuring robust interconnects:

- Solder Paste Printing: A stencil deposits a precise amount of solder paste onto the PCB’s pads, forming the foundation for solder joints. Modern stencil technologies (e.g., laser-cut, electroformed) ensure uniform paste deposition, minimizing defects like insufficient solder or bridging.

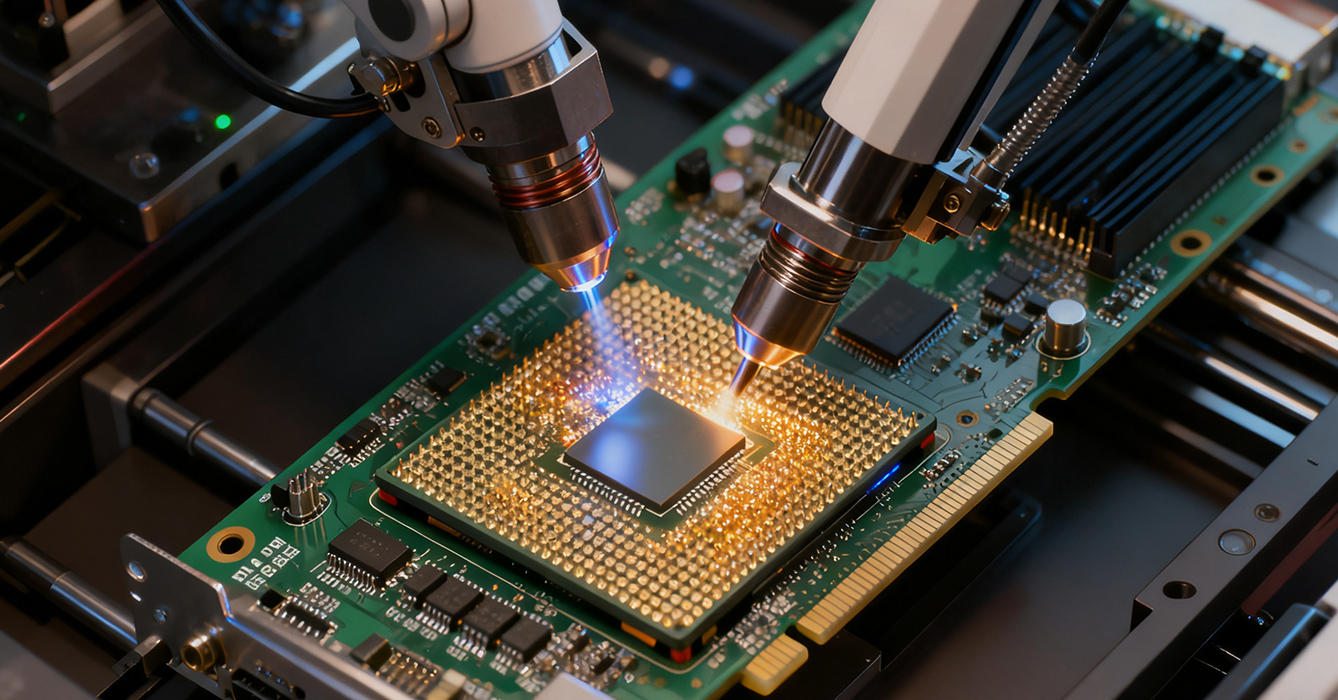

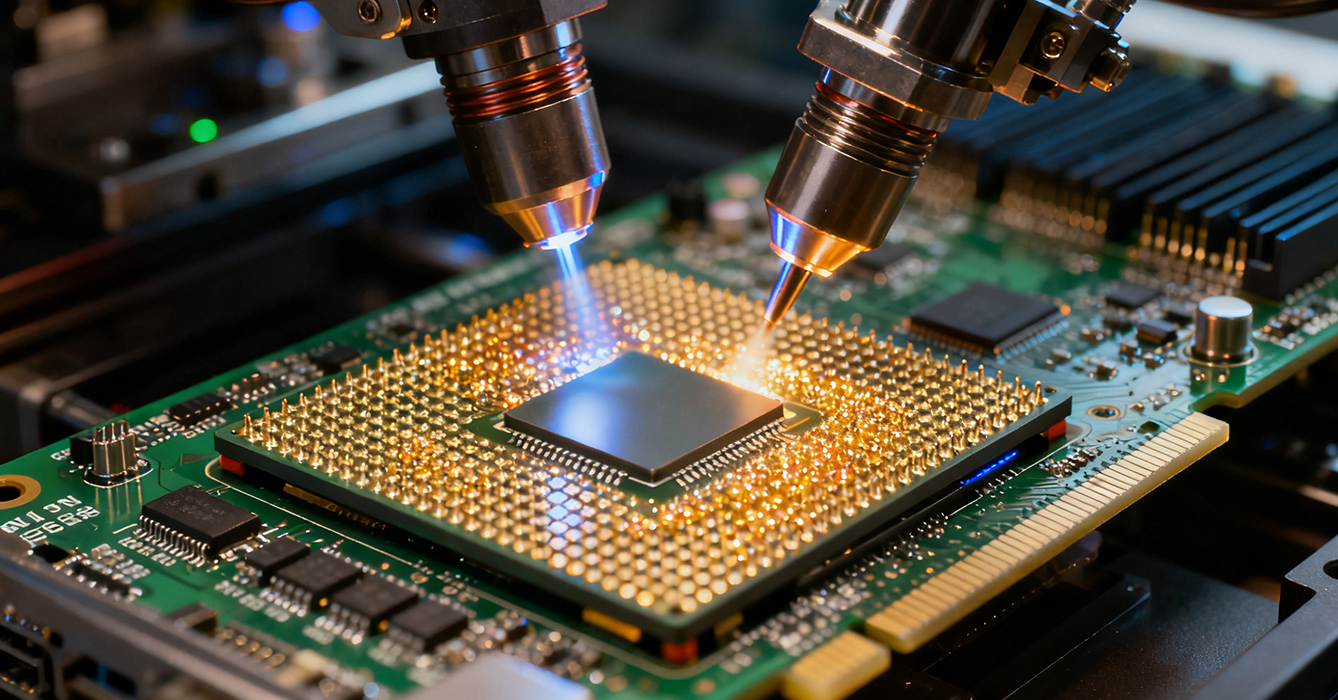

- Chip Placement: Automated pick-and-place machines with high-resolution vision systems align the BGA chip’s solder balls with the PCB’s paste-covered pads. Sub-micron placement accuracy is essential to avoid misalignment, which can cause open circuits or short circuits.

- Reflow Soldering: The PCB moves through a reflow oven, where controlled temperature profiles melt the solder paste. This process forms strong, reliable solder joints as the solder cools and solidifies. Nitrogen-enriched ovens are often used to reduce oxidation and improve solder joint quality.

- Inspection and Testing: Post-assembly inspection uses X-ray systems (to detect hidden solder defects like voids or cold joints) and automated optical inspection (AOI) for surface-level checks. Functional testing ensures the BGA assembly operates as intended under operational conditions.

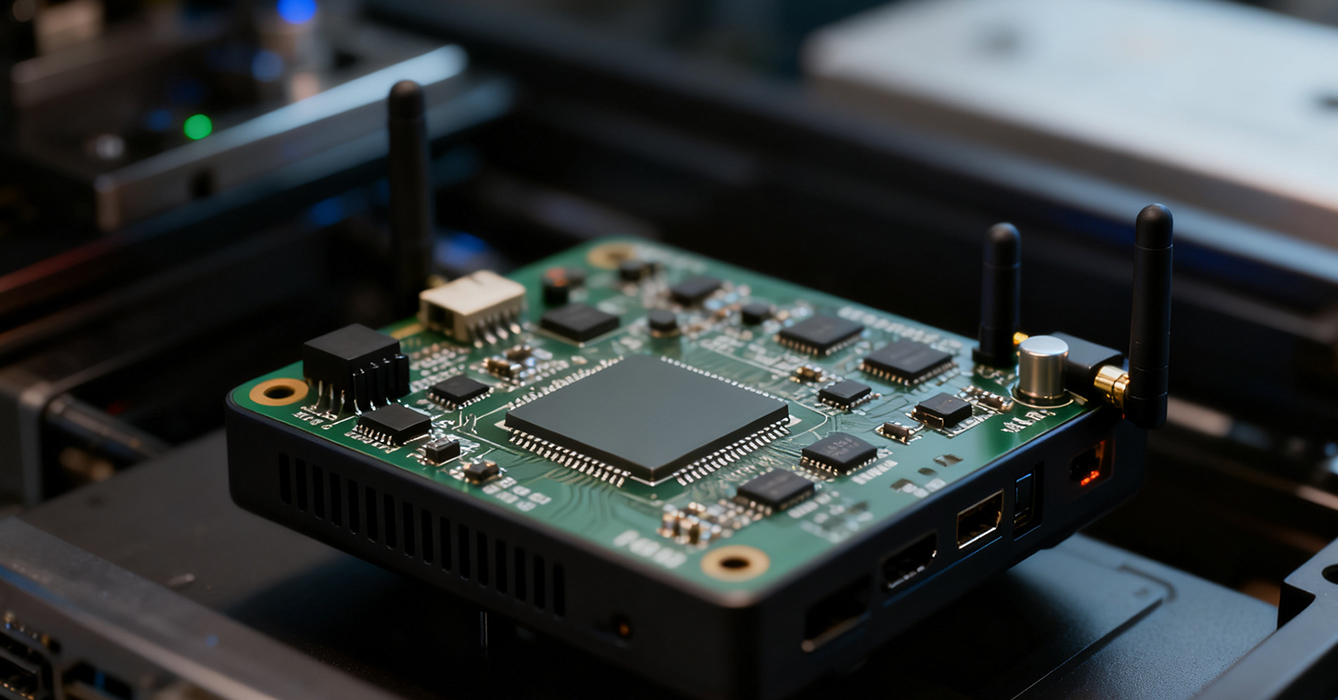

Smartphones, tablets, and laptops rely on BGA assembly for processors, memory chips, and wireless modules. Its high-density design enables thinner, lighter devices without compromising processing power, while improved thermal efficiency extends battery life.

Modern vehicles use BGA assemblies in engine control units (ECUs), infotainment systems, and ADAS (Advanced Driver-Assistance Systems). BGA’s resistance to vibration and temperature fluctuations ensures reliability in harsh automotive environments, from extreme cold to engine bay heat.

Industrial controllers, IoT sensors, and edge computing devices leverage BGA assembly for its durability and signal integrity. In factory automation, BGA-equipped microcontrollers handle real-time data processing, while IoT sensors use compact BGA packages to fit into space-constrained environments.

Voids, cold joints, and bridging are common issues. Solutions include using solder pastes with optimized particle size, implementing closed-loop stencil printing systems, and fine-tuning reflow profiles with AI-driven thermal analysis tools.

High-power chips generate heat that can degrade solder joints. Modern strategies involve integrating thermal vias in PCBs, using thermally conductive underfill materials, and designing heat spreaders that distribute heat away from the BGA assembly.

Balancing precision with high-volume production is a challenge. Manufacturers use modular assembly lines with quick-changeover capabilities and real-time process monitoring (via IoT sensors) to maintain quality while scaling output.

The evolution of BGA assembly is driven by miniaturization and smart manufacturing. Emerging trends include AI-powered process optimization (where machine learning predicts and prevents defects), eco-friendly solder materials (lead-free alloys with lower environmental impact), and integration with advanced packaging (e.g., BGA-on-BGA stacking for even higher density).

BGA Assembly remains a cornerstone of modern electronics manufacturing, offering a balance of density, reliability, and performance across diverse industries. By mastering its core fundamentals, addressing common challenges with innovative strategies, and embracing emerging trends, manufacturers can leverage BGA assembly to meet the demands of next-generation electronic devices. As technology advances, BGA assembly will continue to adapt, solidifying its role as a critical enabler of electronic innovation.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB