-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 03. 2025, 10:21:36

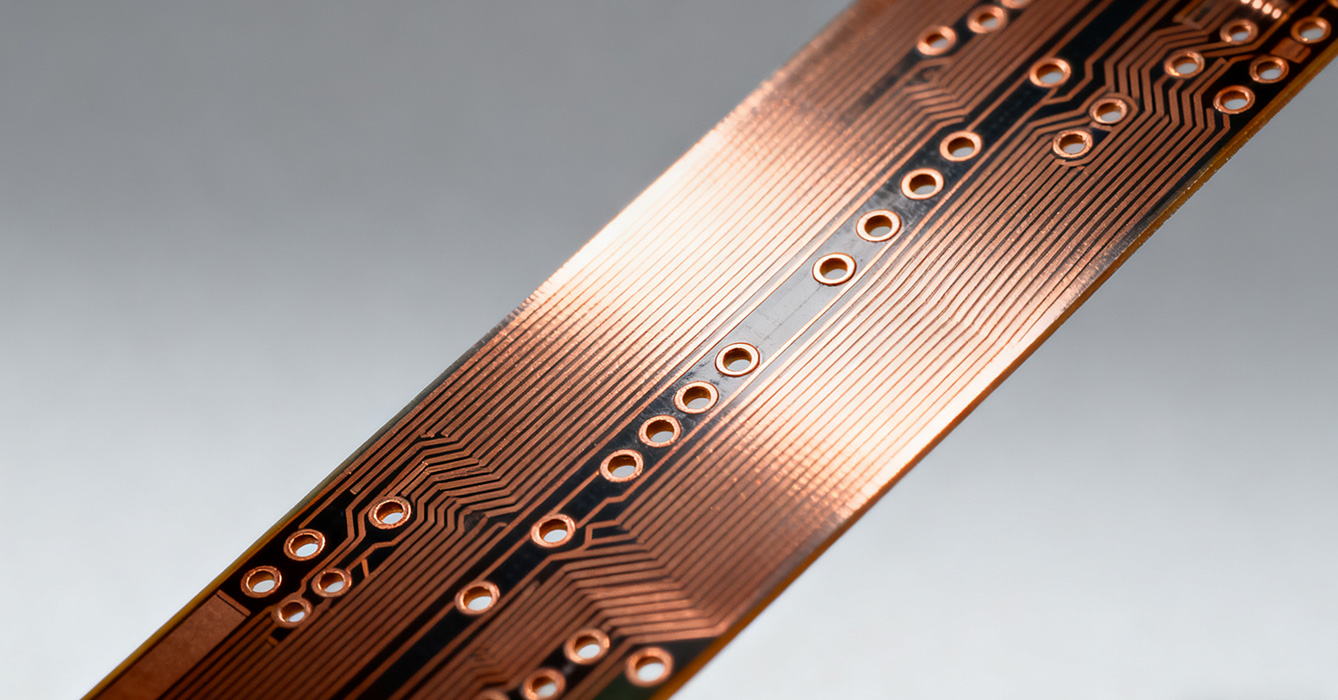

The rapid advancement of radio frequency (RF) technologies—from 5G/6G communications to automotive radar and industrial IoT—has placed unprecedented demands on flexible printed circuits (FPCs). Blind Buried Vias FPC for RF emerges as a specialized solution tailored to the unique requirements of RF applications, where signal integrity, electromagnetic compatibility (EMC), and space efficiency are critical. Unlike standard FPCs with through-hole vias, this advanced FPC integrates blind vias (connecting surface layers to inner layers) and buried vias (connecting only inner layers) to optimize RF signal paths, minimize signal loss, and reduce electromagnetic interference (EMI). For manufacturers of RF devices, partnering with providers of high-quality Blind Buried Vias FPC for RF is essential to unlocking the full potential of next-generation high-frequency electronic systems.

Blind Buried Vias FPC for RF delivers distinct technical benefits that address the core challenges of RF signal transmission and device miniaturization:

- Optimized RF Signal Integrity: RF signals are highly susceptible to loss and distortion, especially at high frequencies (e.g., 5G millimeter-wave bands). Blind and buried vias eliminate the need for through-holes that pierce all layers, shortening signal paths and reducing parasitic capacitance and inductance. This optimization ensures minimal signal attenuation, stable impedance matching, and reliable high-frequency data transmission—critical for RF devices such as 5G base station components, satellite communication modules, and automotive radar systems.

- Reduced Electromagnetic Interference (EMI): EMI is a major concern in RF applications, as it can disrupt signal transmission and affect adjacent electronic components. By confining interlayer connections to inner layers (via buried vias) or surface-to-inner layers (via blind vias), Blind Buried Vias FPC for RF minimizes the exposure of signal paths to the external environment. Additionally, the compact via design allows for tighter grounding and shielding layouts, further suppressing EMI and improving EMC performance.

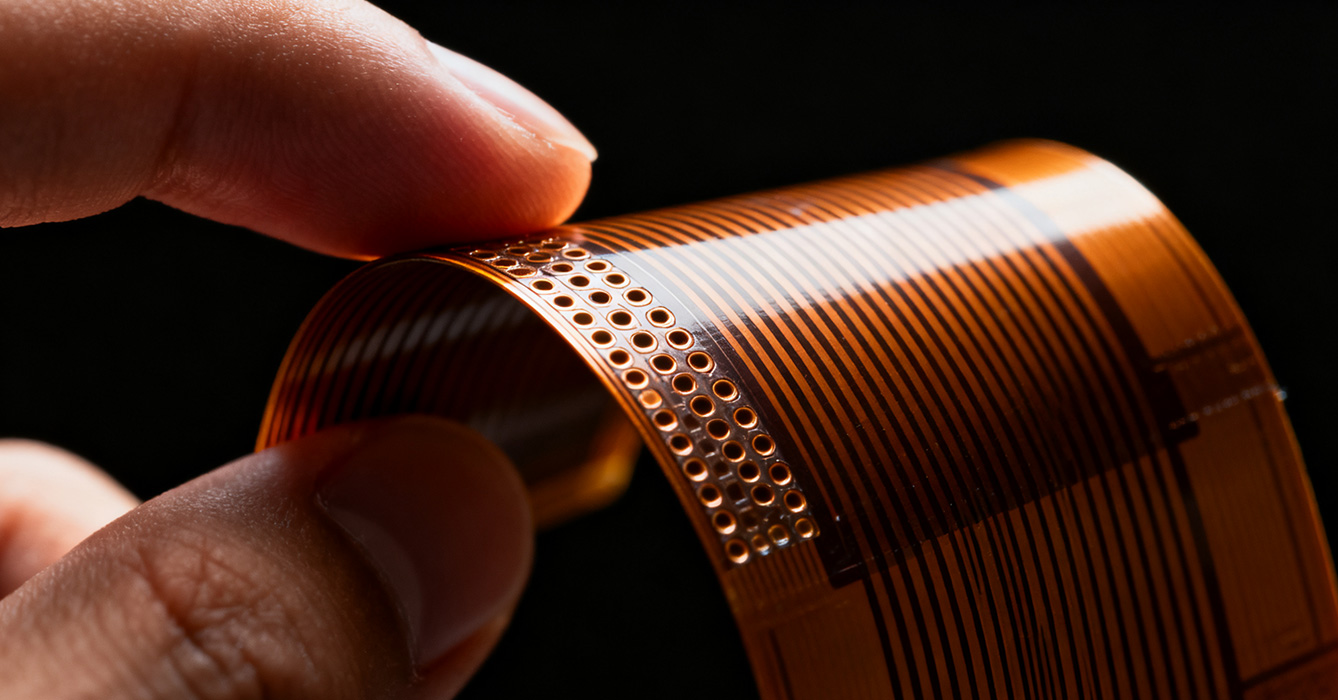

- Enhanced Space Utilization & Miniaturization: RF devices—such as wearable RF sensors, compact IoT modules, and automotive ADAS radar units—demand ultra-miniaturized form factors. Blind and buried vias enable dense interlayer routing without occupying surface space, allowing more RF components (e.g., antennas, filters, amplifiers) to be integrated onto a single FPC. This high-density integration reduces the overall size and weight of RF devices, supporting their deployment in space-constrained applications.

- Improved Mechanical Flexibility & Durability: Unlike rigid PCBs, Blind Buried Vias FPC for RF retains the inherent flexibility of FPCs, enabling it to conform to curved or irregular surfaces in RF devices (e.g., curved automotive radar enclosures, wearable RF gadgets). The absence of through-holes also reduces stress concentration points in the FPC, enhancing its resistance to repeated bending and mechanical fatigue. This durability ensures reliable performance of RF devices in dynamic operating environments.

Designing and manufacturing Blind Buried Vias FPC for RF requires specialized expertise to address the unique challenges of high-frequency applications:

- Precision Via Fabrication: Blind and buried vias for RF applications demand ultra-high manufacturing precision to ensure consistent impedance and signal transmission. Advanced processes such as laser drilling (for micro vias) and plasma desmearing are used to create vias with tight diameter tolerances and clean inner walls. Strict quality control measures—including X-ray inspection—verify via integrity to prevent signal leakage or short circuits.

- High-Frequency Material Selection: The substrate and conductive materials of Blind Buried Vias FPC for RF must be optimized for high-frequency performance. Low-loss dielectric substrates (e.g., high-Tg polyimides with low dielectric constant (Dk) and dissipation factor (Df)) are preferred to minimize signal loss. High-conductivity copper foils (e.g., rolled copper) are used to reduce resistance and improve current-carrying capacity for RF signals.

- Impedance Control: Accurate impedance control is critical for RF signal transmission, as impedance mismatches can cause significant signal reflection and loss. Manufacturers of Blind Buried Vias FPC for RF use advanced design tools to simulate and optimize the layout of vias, traces, and grounding layers. They also implement strict process control during fabrication to ensure that the actual impedance of the FPC matches the designed value.

- Thermal Management for High-Power RF Applications: High-power RF components (e.g., RF amplifiers) generate significant heat, which can degrade FPC performance and component reliability. Blind Buried Vias FPC for RF can integrate thermal vias (a type of blind/buried via) to enhance heat dissipation from high-power components to grounding layers. This targeted thermal management ensures stable operation of RF devices under high-power conditions.

Blind Buried Vias FPC for RF is indispensable in a range of high-frequency RF applications, enabling innovation and performance enhancement:

- 5G/6G Communications: Powers 5G/6G base station components, user equipment (e.g., 5G smartphones, portable 5G hotspots), and millimeter-wave modules. The optimized signal integrity and compact design of Blind Buried Vias FPC support high-speed, low-latency RF signal transmission, a core requirement for 5G/6G technologies.

- Automotive RF Systems: Enables automotive radar (e.g., lidar, ultrasonic radar), in-vehicle infotainment systems, and V2X (Vehicle-to-Everything) communication modules. The EMI suppression and mechanical flexibility of this FPC ensure reliable performance in the harsh automotive environment (extreme temperatures, vibration, electromagnetic noise).

- Industrial IoT & Wireless Sensing: Supports industrial RF sensors, wireless communication modules, and edge computing devices for IoT applications. The miniaturized design and low signal loss of Blind Buried Vias FPC enable the deployment of compact, high-performance RF devices in industrial settings, facilitating smart manufacturing and industrial automation.

- Aerospace & Satellite Communications: Provides high-reliability RF FPCs for aerospace avionics, satellite communication systems, and space exploration equipment. The high signal integrity, EMI resistance, and lightweight design of Blind Buried Vias FPC meet the stringent requirements of aerospace RF applications, where performance and reliability are critical.

In conclusion, Blind Buried Vias FPC for RF is a specialized and critical component for high-performance RF electronic systems. By optimizing signal integrity, reducing EMI, enhancing space utilization, and ensuring mechanical flexibility, it addresses the core challenges of modern RF applications. As RF technologies continue to advance toward higher frequencies and miniaturization, the demand for high-quality Blind Buried Vias FPC for RF will only grow. For manufacturers seeking to develop competitive RF devices, partnering with a provider with expertise in designing and manufacturing this specialized FPC is a strategic investment in product performance and market success.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB