-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 13. 2025, 13:05:52

In the dynamic landscape of modern electronics, the relentless pursuit of enhanced performance, miniaturization, and reliability has led to significant advancements in printed circuit board (PCB) technology. Metal - Core PCBs (MCPCBs) and blind and buried vias have emerged as key elements in this evolution, enabling the creation of more efficient and compact electronic systems. MCPCBs, with their unique structure, offer superior thermal management capabilities, while blind and buried vias play a crucial role in optimizing electrical connectivity and space utilization within PCBs. This article explores the integration of blind and buried vias in metal - core PCBs, delving into their significance, design considerations, manufacturing processes, quality control, applications, challenges, and future trends.

Basics of Metal - Core PCBs and Blind/Buried Vias

Metal - Core PCBs

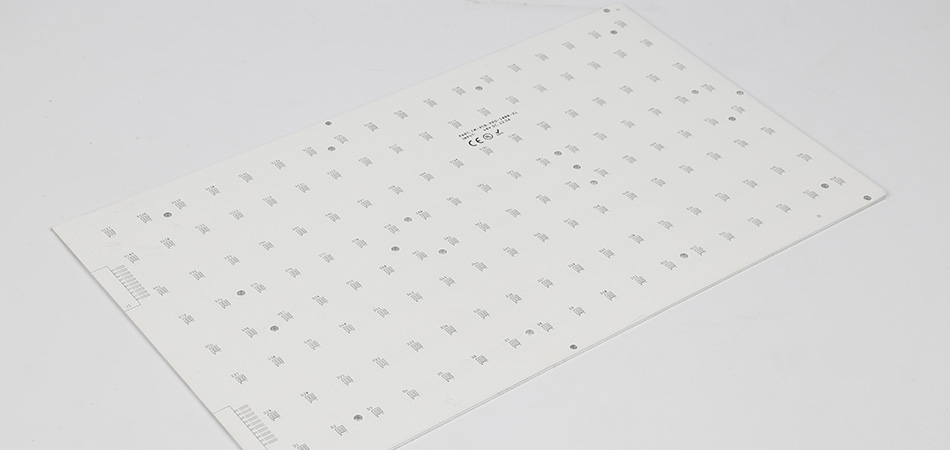

Metal - Core PCBs feature a three - layer construction. The metal core, typically made of aluminum or copper, serves as an efficient heat sink, facilitating the dissipation of heat generated by high - power components. Aluminum is often favored for its balance of thermal conductivity, mechanical strength, and cost - effectiveness, making it a popular choice for applications like LED lighting and consumer electronics. Copper, on the other hand, boasts even higher thermal conductivity, making it ideal for high - performance scenarios such as power electronics in electric vehicles or high - end computing systems.

The insulating dielectric layer, positioned between the metal core and the top conductive layer, provides electrical isolation while allowing for the transfer of thermal energy. Composed of materials like thermally conductive epoxy resins, its properties are carefully engineered to strike the right balance between preventing electrical short - circuits and enabling efficient heat transfer. The top layer, usually composed of copper, contains the etched electrical traces that form the circuit pathways. This structure endows MCPCBs with excellent thermal conductivity and mechanical strength, making them ideal for applications where heat management and ruggedness are critical, such as in LED lighting, automotive electronics, and power supplies.

Blind and Buried Vias

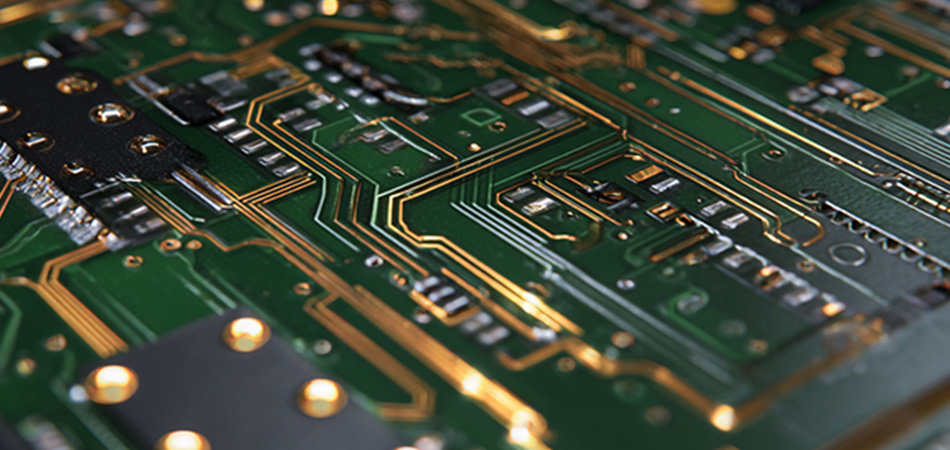

Vias are essential components in PCBs, acting as electrical connections between different layers. Blind vias connect an outer layer to one or more inner layers without extending through the entire board, while buried vias connect two or more inner layers without reaching the surface. Unlike through - hole vias that penetrate the entire PCB, blind and buried vias save valuable space on the PCB surface, enabling higher component density and more complex circuit routing.

The ability to route signals within the internal layers of the PCB using blind and buried vias reduces the need for surface - level connections that can take up space and potentially interfere with other components. This makes them particularly suitable for high - density interconnect (HDI) designs, where space optimization and signal integrity are of utmost importance. For instance, in a multi - layer PCB with a complex network of components, blind vias can connect surface - mounted components to internal circuitry, while buried vias can establish connections between different internal layers, creating a more streamlined and efficient circuit layout.

Significance of Blind and Buried Vias in Metal - Core PCBs

Space Optimization

In metal - core PCBs, blind and buried vias significantly contribute to space savings. By eliminating the need for through - hole vias that span the entire board, they free up surface area on both the top and bottom layers. This extra space can be utilized for additional component placement or more intricate routing, allowing for a denser component layout.

In compact electronic devices, such as smartphones and wearables, where every millimeter of space is precious, the use of blind and buried vias enables the integration of more features within a limited form factor. For example, in a smartwatch, the reduced footprint of blind and buried vias allows for the inclusion of additional sensors, a more powerful battery, or a smaller and more ergonomic design. In high - density server boards, these vias enable the packing of more components onto a single PCB, increasing computational power while keeping the overall size of the server manageable.

Electrical Performance Enhancement

Blind and buried vias play a vital role in improving the electrical performance of metal - core PCBs. They reduce the length of electrical connections compared to through - hole vias, minimizing signal propagation delays, crosstalk, and electromagnetic interference (EMI). In high - frequency applications, such as 5G communication modules and high - speed data processing systems, these vias ensure accurate and reliable signal transmission, maintaining the integrity of the electronic circuit.

The shorter signal paths also contribute to lower signal attenuation, enhancing the overall performance of the PCB. For example, in a 5G base station's radio frequency (RF) circuit, blind and buried vias help in maintaining the quality of high - frequency signals, ensuring seamless communication between the base station and mobile devices. In high - speed data transfer interfaces like USB 4.0 or Thunderbolt, these vias enable faster and more stable data transmission by reducing signal losses and interference.

Thermal Management Synergy

When integrated into metal - core PCBs, blind and buried vias can work in tandem with the metal core to enhance thermal management. They can be strategically placed to create thermal pathways, facilitating the transfer of heat from components to the metal core. This synergy ensures efficient heat dissipation, preventing hotspots and maintaining optimal operating temperatures, even in high - power applications.

For example, in power - intensive LED lighting fixtures, the combination of a metal - core PCB and properly placed blind and buried vias helps to keep the LEDs cool, extending their lifespan and ensuring consistent performance. The vias act as conduits, allowing heat generated by the LEDs to quickly reach the metal core, which then dissipates the heat into the surrounding environment. In automotive engine control units (ECUs), where components operate in a high - temperature environment, blind and buried vias assist in effectively managing heat, ensuring the reliable operation of the ECU and the overall vehicle systems.

Design Considerations for Blind and Buried Vias in Metal - Core PCBs

Via Placement

The placement of blind and buried vias in metal - core PCBs requires careful planning. Vias should be positioned away from sensitive components, such as antennas, oscillators, and high - speed signal traces, to avoid interference. Antennas, for instance, can be highly sensitive to the electromagnetic fields generated by nearby vias, which could distort their radiation patterns and reduce communication range.

They should also be located to optimize electrical routing, ensuring short and direct signal paths. Designers often use electromagnetic field simulation tools to analyze the behavior of signals around vias and make informed placement decisions. Additionally, vias should be placed in a way that does not compromise the mechanical integrity of the PCB, especially in areas subject to mechanical stress or vibration. For example, in automotive or aerospace applications, where the PCB may experience significant vibrations, vias should be placed in areas that can withstand these forces without cracking or causing damage to the surrounding circuitry.

Via Size and Aspect Ratio

The size of blind and buried vias, including their diameter and depth, affects both the electrical and mechanical performance of the PCB. Smaller vias allow for higher circuit density but may increase manufacturing complexity. The aspect ratio, which is the ratio of via depth to diameter, also needs to be carefully considered. A high aspect ratio can pose challenges in drilling and plating, potentially affecting via reliability.

During drilling, a high aspect ratio may cause the drill bit to deflect or break, leading to inconsistent hole quality. In plating, it can be difficult to achieve uniform copper deposition, resulting in voids or thin spots that can compromise the electrical conductivity of the via. Designers must balance the need for high circuit density with the manufacturability of the vias, taking into account the specific requirements of the application, such as the operating frequency, power levels, and signal integrity requirements. For high - frequency applications, smaller vias with carefully controlled aspect ratios are often preferred to minimize parasitic effects and maintain signal integrity.

Interaction with PCB Layers

Blind and buried vias interact with the different layers of the metal - core PCB in various ways. When connecting to the metal core for thermal purposes, proper insulation must be maintained to prevent electrical short - circuits. The insulating dielectric layer around the vias should have sufficient thickness and dielectric strength. Any compromise in the insulation can lead to electrical leakage, which can cause malfunctions or even damage to the components on the PCB.

Additionally, the copper layers need to be designed to accommodate the vias without compromising the integrity of the electrical traces. The width of the traces near the vias may need to be adjusted to account for the current - carrying capacity requirements. The lamination process, which bonds the different layers of the PCB together, must be carefully controlled to ensure that the vias are properly aligned and connected between the layers, avoiding misalignment that could lead to electrical failures. Special attention must be paid to the compatibility of materials used in different layers to prevent issues such as delamination or warping over time.

Manufacturing Processes for Blind and Buried Vias in Metal - Core PCBs

Drilling

Precision drilling is the first step in creating blind and buried vias in metal - core PCBs. Two common drilling techniques are laser drilling and mechanical drilling. Laser drilling offers high precision and the ability to create small - diameter vias, making it suitable for high - density applications. It uses a focused laser beam to ablate the PCB material, creating holes with tight tolerances. The laser can be precisely controlled to drill holes of specific diameters and depths, allowing for the creation of micro - vias that are essential in HDI designs.

Mechanical drilling, on the other hand, is more cost - effective for larger production volumes and can handle a wider range of via sizes. In mechanical drilling, a rotating drill bit made of carbide or diamond - coated materials is used to physically cut through the PCB layers. Advanced computer - numerical - control (CNC) machines are employed to ensure accurate hole placement and depth control. However, mechanical drilling may be more prone to issues such as burr formation and drill bit wear, which need to be carefully managed to maintain hole quality.

Plating

After drilling, the vias need to be plated to create electrical connections. The plating process typically starts with electroless copper plating. This method deposits a thin, uniform layer of copper on the non - conductive surfaces of the drilled vias without the need for an external electrical current. The electroless copper layer serves as a seed layer for the subsequent electroplating process, providing a conductive surface for the deposition of additional copper.

Electroplating follows, where an electric current is passed through a copper - containing solution, causing copper ions to deposit onto the vias. Precise control of plating parameters, such as the composition of the plating solution, temperature, and the applied electric current, is crucial to ensure consistent plating quality. The thickness of the copper plating must be carefully controlled to meet the electrical requirements of the circuit, while also ensuring good adhesion to the via walls to prevent issues like delamination or poor conductivity over time.

Lamination and Bonding

For buried vias, additional lamination and bonding processes are required. Multiple PCB layers, each with pre - drilled vias, are carefully stacked in the correct order. Alignment pins or optical alignment systems are used to ensure precise alignment of the vias between layers. The stacked layers are then bonded together under high pressure and temperature. Specialized adhesives with excellent thermal and electrical properties are used in the lamination process to create a strong and reliable bond between the layers.

The lamination process must be carefully monitored to ensure that there are no voids, delaminations, or misalignments in the final PCB. Any imperfections in the lamination can lead to electrical failures or mechanical weaknesses in the PCB, compromising its performance and reliability. After lamination, the PCB may undergo additional processes such as surface finishing and component assembly to complete the manufacturing process.

Quality Control and Inspection

Dimension Inspection

Precision measuring tools are employed to conduct dimension inspection of blind and buried vias. Optical microscopes are commonly used to visually inspect the diameter and position of the vias. They provide a detailed view of the via structure, allowing inspectors to detect any deviations from the design specifications. Scanning electron microscopes (SEM) offer even higher magnification and resolution, enabling the examination of the via walls at a microscopic level to check for any irregularities or defects.

3D coordinate measuring machines (CMMs) are used to accurately measure the depth and position of the vias in three - dimensional space. These tools can provide precise measurements of the via dimensions, ensuring that they meet the tight tolerances required for metal - core PCBs. Any deviation in the via dimensions can affect the electrical and mechanical performance of the PCB, so strict dimension inspection is essential to maintain quality.

Electrical Testing

Electrical tests are performed to verify the functionality of blind and buried vias. Continuity testing is carried out to check for open circuits in the vias. A small electrical current is applied through the via, and the resulting voltage is measured. If the voltage drop is within an acceptable range, it indicates a continuous electrical path. Insulation resistance testing is conducted to ensure that there is no electrical leakage between the vias and other PCB layers or components. High - resistance values are expected, indicating good insulation.

Impedance testing is particularly important for high - frequency applications. Specialized impedance - measuring instruments are used to measure the impedance of the vias. The measured impedance should match the design requirements to ensure signal integrity. Any significant deviation from the desired impedance can cause signal reflections, leading to reduced signal quality and potential circuit malfunctions.

Microsection Analysis

Microsection analysis involves cutting a cross - section of the PCB through the vias and examining it under a microscope. This method provides a detailed view of the via structure, including the quality of the copper plating, the integrity of the insulating layer around the via, and the bonding between layers. Microsection analysis can reveal defects such as cracks in the copper plating, delamination of the insulating layer, or improper filling of the via with the plating material.

In metal - core PCBs, where the performance of the vias is critical, microsection analysis is an effective way to detect hidden defects that may not be visible through other inspection methods. It allows for a comprehensive evaluation of the via quality and helps to ensure the reliability of the PCB. Regular microsection analysis during the manufacturing process can help identify and address any issues early, preventing costly rework or product failures.

Applications of Blind and Buried Vias in Metal - Core PCBs

Consumer Electronics

In the consumer electronics sector, blind and buried vias in metal - core PCBs are widely used. Smartphones, for example, rely on these advanced via technologies to integrate multiple components, such as high - resolution cameras, powerful processors, and 5G communication modules, into a compact form factor. The space - saving and electrical performance - enhancing features of blind and buried vias enable the creation of slimmer, more powerful smartphones with longer battery life and better connectivity.

Tablets and laptops also benefit from the use of metal - core PCBs with blind and buried vias. These vias allow for the efficient routing of signals between components, reducing electromagnetic interference and improving the overall performance of the devices. In addition, the enhanced thermal management capabilities of metal - core PCBs help to keep the components cool during intense usage, preventing performance throttling and extending the lifespan of the devices.

Automotive Electronics

Automotive electronics is another key application area for blind and buried vias in metal - core PCBs. In modern vehicles, there is a growing demand for advanced electronic systems, such as engine control units (ECUs), advanced driver - assistance systems (ADAS), and in - vehicle infotainment systems. These systems require PCBs that can withstand harsh environmental conditions, including high temperatures, vibrations, and electrical noise.

Metal - core PCBs with blind and buried vias offer the necessary thermal management, mechanical strength, and electrical performance to meet these requirements. The vias enable the compact integration of multiple components, reducing the size and weight of the PCBs, which is crucial for automotive applications where space is limited. The enhanced electrical performance also ensures the reliable operation of critical systems, improving vehicle safety and performance.

Industrial Electronics

In industrial electronics, metal - core PCBs with blind and buried vias are used in a variety of applications, including power electronics modules, industrial control panels, and robotic systems. Power electronics modules, which are used to convert and control electrical power, often generate a significant amount of heat. The combination of a metal - core PCB and blind and buried vias allows for efficient heat dissipation, ensuring the reliable operation of the power - handling components.

In industrial control panels, where precise and reliable electrical connections are essential, blind and buried vias enable the creation of complex circuit layouts in a compact space. They help to reduce electromagnetic interference, ensuring the accurate operation of the control systems. In robotic systems, the use of these advanced vias in metal - core PCBs allows for the integration of multiple sensors, actuators, and control units, enabling precise and reliable robotic movements.

Aerospace and Defense

The aerospace and defense industries have stringent requirements for the reliability and performance of electronic components. Metal - core PCBs with blind and buried vias are used in avionics systems, radar equipment, missile guidance systems, and satellite electronics. These vias enable the creation of compact, high - density PCBs that can withstand the extreme conditions encountered in aerospace and defense applications, such as high - altitude pressures, rapid temperature changes, and intense vibrations.

The enhanced electrical performance of blind and buried vias ensures the accurate transmission of critical signals in avionics and radar systems, while the efficient thermal management provided by the metal - core PCB helps to maintain the optimal operating temperature of the components. In missile guidance systems and satellite electronics, the reliability and compactness of these PCBs are crucial for the success of missions and the safety of personnel.

Current Challenges

The manufacturing of blind and buried vias in metal - core PCBs faces several challenges. The miniaturization of vias, which is necessary to achieve higher circuit densities, requires extremely high precision in drilling and plating processes. As the diameter of vias decreases, it becomes more difficult to drill straight holes and achieve uniform copper deposition. This increases the complexity and cost of production, as more advanced manufacturing equipment and techniques are required.

Ensuring consistent quality across a large production volume is also a significant challenge. Even small variations in the manufacturing process, such as differences in drilling speed, plating solution composition, or lamination pressure and temperature, can lead to defective vias.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB