-

- PCB TYPE

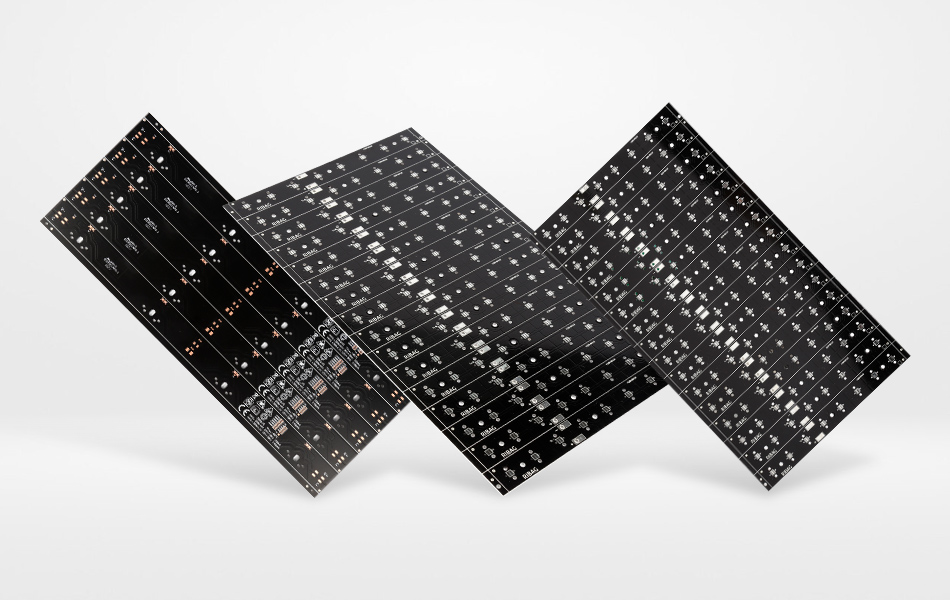

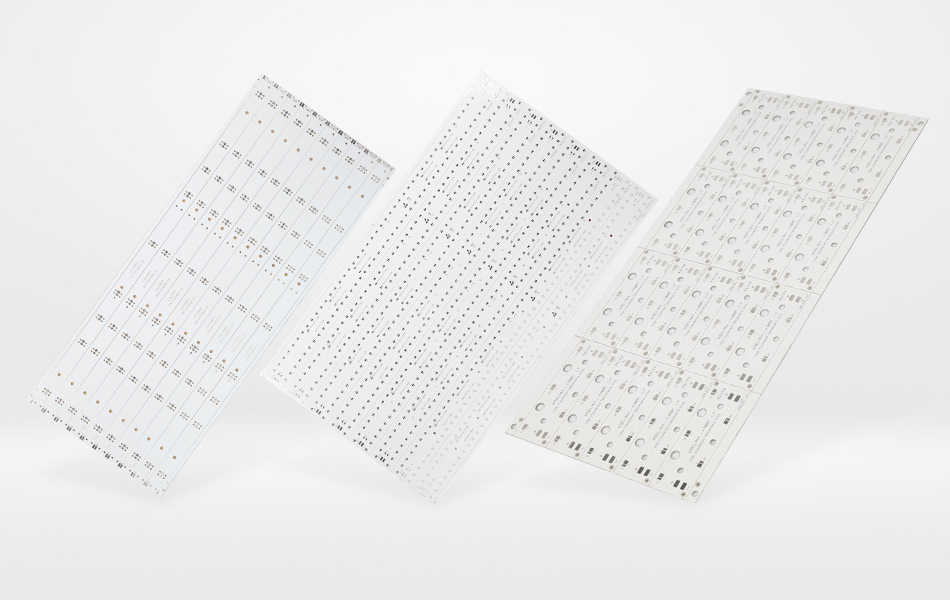

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 15. 2025, 09:32:30

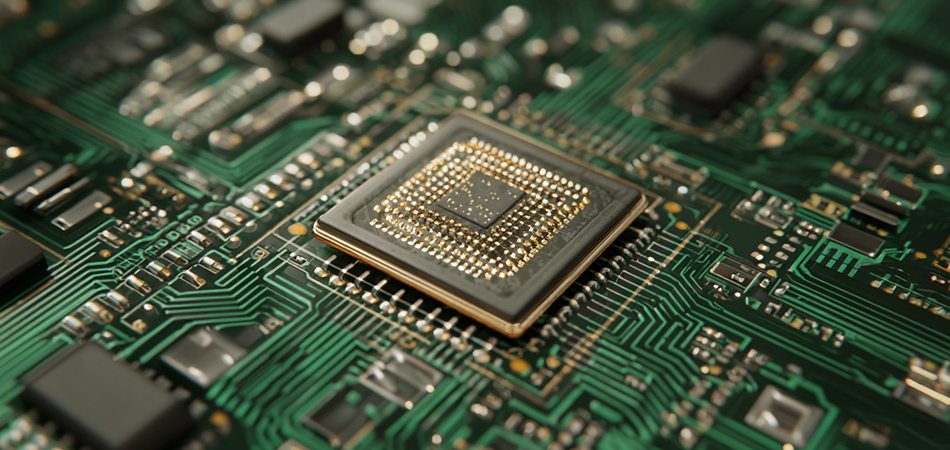

In an era where electronic devices demand ever-higher power densities and miniaturization, effective thermal management has become a critical bottleneck. Boyu's High Thermal Aluminum Copper Clad Laminates (CCLs) address this challenge by delivering unprecedented heat dissipation capabilities, enabling next-generation applications in 5G infrastructure, electric vehicles (EVs), and industrial systems. This article explores Boyu's technical innovations, application-specific solutions, and industry impact in high thermal aluminum CCLs, emphasizing its role in overcoming thermal limitations across sectors.

Core Innovations in High Thermal Aluminum CCL Design

Advanced Material Composites

Boyu's high thermal CCLs leverage cutting-edge material science to achieve superior heat transfer:

Diamond-Enhanced Aluminum Cores: By embedding synthetic diamond particles into aluminum alloys, Boyu creates a thermally conductive matrix with heat dissipation rates exceeding traditional aluminum by 200%. This composite structure balances high thermal conductivity (exceeding 300 W/mK) with mechanical stability, making it ideal for power electronics.

Graphene-Infused Dielectrics: Integrating graphene nanosheets into dielectric layers enhances both thermal conductivity and electrical insulation. This innovation reduces interfacial thermal resistance by 40%, ensuring efficient heat transfer from copper traces to the aluminum core.

Ceramic-Filled Adhesives: Proprietary ceramic-reinforced adhesives eliminate thermal bottlenecks at material interfaces, maintaining uniform heat distribution across the laminate.

These material advancements position Boyu's CCLs as leaders in thermal performance without compromising electrical integrity.

Structural Optimization for Heat Dissipation

Boyu engineers laminate architectures to maximize thermal efficiency:

Micro-Channel Cooling Design: Laser-etched micro-channels within the aluminum core allow for embedded liquid cooling systems, a critical feature in high-power applications like 5G base stations and AI servers.

Multi-Layer Thermal Gradient: By strategically layering materials with varying thermal conductivities, Boyu creates a gradient that directs heat away from sensitive components, reducing hotspots by 30% compared to conventional designs.

Thin-Film Copper Cladding: Ultra-thin copper layers (down to 18μm) minimize resistive heating while maintaining high current-carrying capacity, a balance essential for compact EV charging modules.

Applications in High-Power Electronics

5G and Next-Generation Communication

Boyu's high thermal CCLs are pivotal in 5G infrastructure:

mmWave Antenna Arrays: Dielectrics with ultra-low loss (Df < 0.002 at 10 GHz) and high thermal conductivity enable efficient heat dissipation in 5G mmWave modules, extending signal range while preventing performance degradation due to thermal stress.

Base Station Power Amplifiers: Aluminum cores with diamond composites manage heat generated by high-output amplifiers, ensuring stable operation in extreme temperatures (up to 125°C).

Electric Vehicles and Energy Storage

In EVs and battery systems, Boyu's CCLs solve critical thermal challenges:

Battery Management Systems (BMS): CCLs with graphene-enhanced dielectrics provide rapid heat dissipation from battery cells, maintaining uniform temperature distribution and extending cycle life.

High-Power Inverters: Diamond-aluminum cores handle the intense heat generated by EV inverters, supporting fast-charging capabilities (800V systems) without compromising reliability.

Thermal Runaway Prevention: By integrating phase-change materials (PCMs) into the CCL structure, Boyu's solutions absorb excess heat during thermal excursions, enhancing safety in battery packs.

Industrial and Renewable Energy

Boyu's CCLs excel in harsh industrial environments:

Solar Inverters: UV-stabilized aluminum cores with ceramic-filled dielectrics ensure 25+ year durability in outdoor solar installations, withstanding temperature fluctuations and corrosive elements.

Wind Turbine Converters: Thick-copper CCLs (up to 12oz) enable high-current power distribution while minimizing resistive losses, critical for maximizing energy harvest in wind farms.

Industrial Motor Controls: Diamond-reinforced aluminum cores dissipate heat from high-frequency motors, reducing downtime and maintenance costs in manufacturing facilities.

Testing and Validation for Reliability

Thermal Performance Analysis

Boyu employs advanced testing methodologies:

Laser Flash Analysis: Measures thermal diffusivity and conductivity across the laminate, ensuring compliance with industry standards (e.g., ASTM E1461).

Thermal Infrared Imaging: Real-time heat mapping identifies hotspots and validates thermal gradient designs, critical for mission-critical applications like aerospace electronics.

Thermal Cycling Tests: Simulates 5,000+ cycles between -40°C and +125°C to verify resistance to delamination and material fatigue.

Electrical and Mechanical Validation

Dielectric Strength Testing: Ensures insulation integrity under high voltage (up to 10kV), essential for safety in power electronics.

Mechanical Stress Analysis: Dynamic bending and vibration tests confirm structural robustness, particularly in flexible CCLs for wearable devices.

EMI Shielding Effectiveness: Measures attenuation of electromagnetic interference, critical for ADAS radar systems and medical devices.

Sustainable Manufacturing and Circular Economy

Eco-Friendly Materials

Boyu prioritizes sustainability through:

Recycled Aluminum Integration: Post-industrial aluminum scrap constitutes 30% of core material, reducing virgin resource consumption without compromising thermal performance.

Bio-Based Resins: Plant-derived epoxy formulations replace petroleum-based materials in dielectric layers, cutting carbon emissions by 25% per unit.

Lead-Free Processing: RoHS-compliant manufacturing eliminates hazardous substances, aligning with global environmental regulations.

Closed-Loop Recycling

Boyu's proprietary recycling process recovers 95% of aluminum and copper from end-of-life CCLs, diverting e-waste from landfills. The recycled materials are reintegrated into new CCL production, creating a circular material economy.

Global Market Strategy and Customer Collaboration

Regionalized Support

Boyu maintains technical centers in key markets:

Europe: Focuses on automotive and industrial applications, offering IATF 16949-certified CCLs for EV drivetrains and smart factories.

North America: Collaborates with tech giants on 5G infrastructure and AI server solutions, leveraging rapid prototyping for next-gen data centers.

Asia-Pacific: Caters to consumer electronics and renewable energy sectors, providing high-volume production of Mini LED and solar CCLs.

Customized Solutions

Boyu partners with clients to develop tailored CCLs:

Application-Specific Design: Engineers work with customers to optimize laminate thickness, thermal conductivity, and dielectric properties for unique requirements (e.g., cryogenic stability for quantum computing).

Rapid Prototyping: Advanced LDI and laser machining enable quick-turn samples, reducing time-to-market for innovative products like flexible EV battery sensors.

Long-Term Supply Chain Partnerships: Diversified sourcing and regional production facilities ensure stability, even during global material shortages.

Future Directions in Thermal Innovation

Next-Gen Material Platforms

Boyu's R&D pipeline includes:

Graphene-Aluminum Nanocomposites: Targeting thermal conductivity exceeding 400 W/mK for next-gen EV fast-charging systems.

Self-Healing Dielectrics: Smart materials that autonomously repair micro-cracks caused by thermal stress, enhancing long-term reliability in extreme environments.

3D-Printed Thermal Structures: Additive manufacturing of customized heat sinks integrated into CCLs, enabling complex geometries for aerospace and defense applications.

Digitalization and AI Integration

Boyu is developing an AI-driven design tool that:

Predicts thermal performance using machine learning models trained on thousands of material datasets.

Optimizes laminate configurations for specific applications, reducing design iterations by 50%.

Monitors real-time thermal behavior via embedded sensors, enabling predictive maintenance in critical systems like power grids.

Conclusion

Boyu's High Thermal Aluminum CCLs represent a paradigm shift in thermal management for advanced electronics. By combining diamond and graphene composites, structural innovation, and sustainable practices, Boyu empowers industries to overcome thermal limitations and drive technological progress. From 5G networks to electric mobility, Boyu's solutions ensure reliability, efficiency, and scalability in high-power applications. As electronic systems evolve toward higher performance and energy density, Boyu remains at the forefront, enabling a future where heat is no longer a barrier to innovation.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB