-

- PCB TYPE

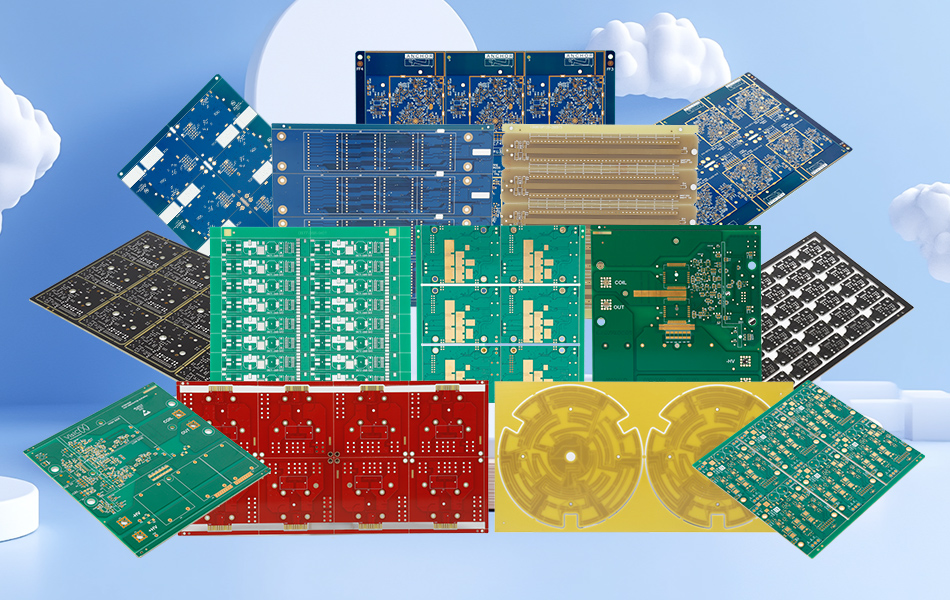

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 28. 2025, 10:05:59

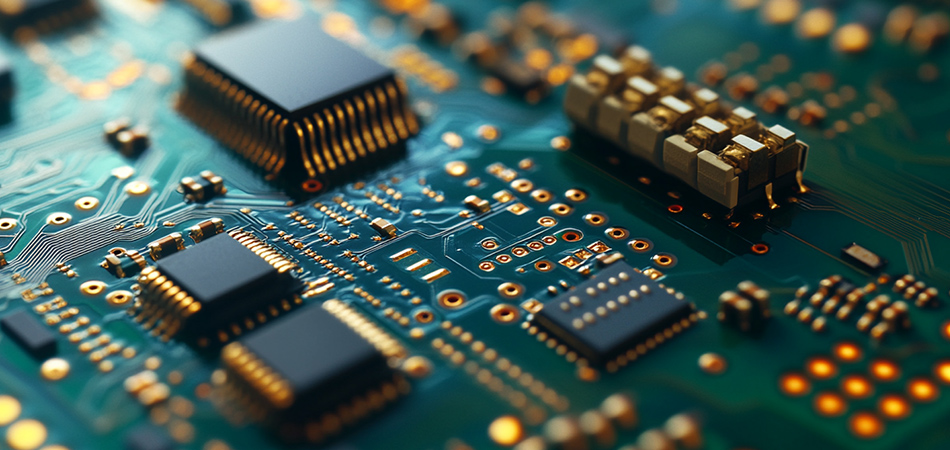

In the global electronics manufacturing landscape, China FR4 PCB Manufacturing Factory has emerged as a cornerstone of innovation, reliability, and scalability, supplying high-quality FR4 printed circuit boards to industries spanning consumer electronics, industrial automation, telecommunications, and medical devices. Leveraging advanced manufacturing technologies, robust supply chain integration, and a focus on quality compliance, Chinese FR4 PCB factories deliver tailored solutions that balance performance, cost efficiency, and rapid production turnaround. This article explores the manufacturing capabilities, technical expertise, quality standards, industry applications, and global impact of China FR4 PCB Manufacturing Factories, ensuring industry professionalism (industry expertise) and alignment with search engine optimization (SEO) best practices.

Manufacturing Capabilities of China FR4 PCB Factories

China FR4 PCB Manufacturing Factories are equipped with state-of-the-art infrastructure and processes to handle diverse production needs, from prototype development to mass production:

Advanced Production Infrastructure

Automated Manufacturing Lines: Modern factories utilize automated lamination, etching, and drilling systems to ensure precision and consistency across production batches. Robotics and AI-driven quality checks minimize human error, enhancing repeatability in critical processes like layer alignment and trace etching.

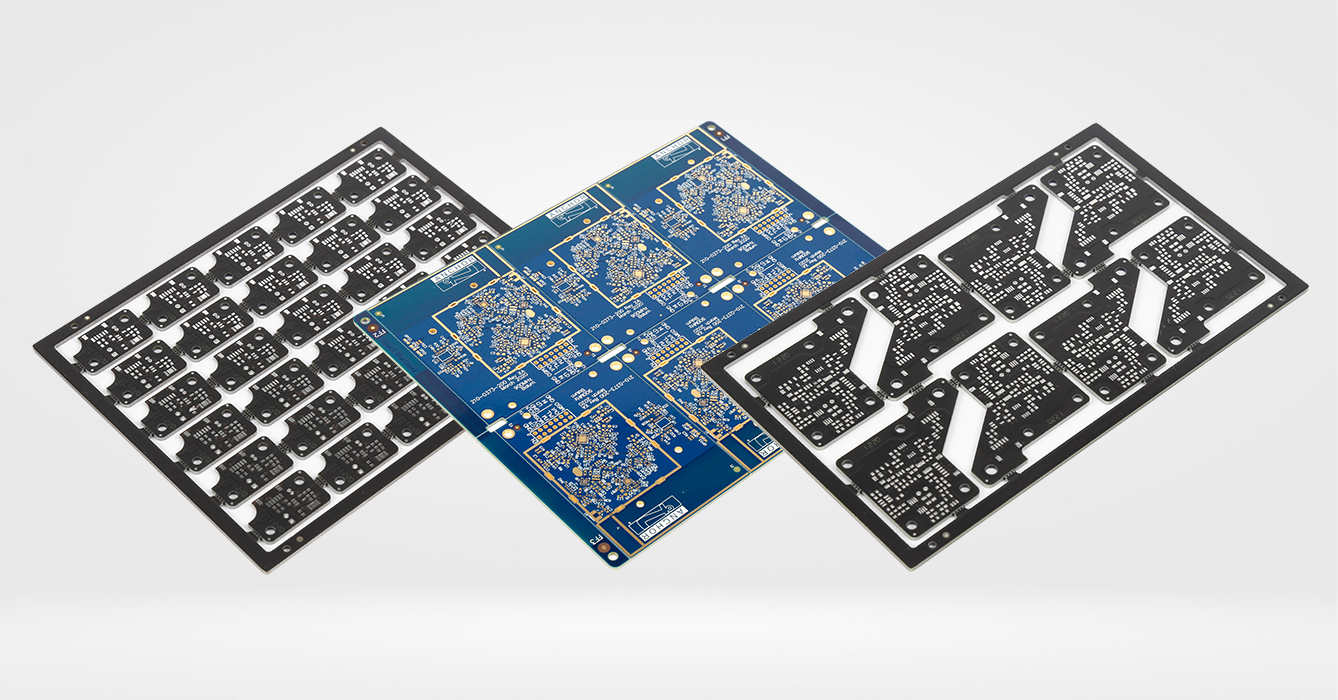

Multi-Layer PCB Expertise: Chinese factories specialize in manufacturing FR4 PCBs with varying layer counts, from single-layer boards to high-density multi-layer designs. This versatility supports applications ranging from simple consumer devices to complex industrial control systems.

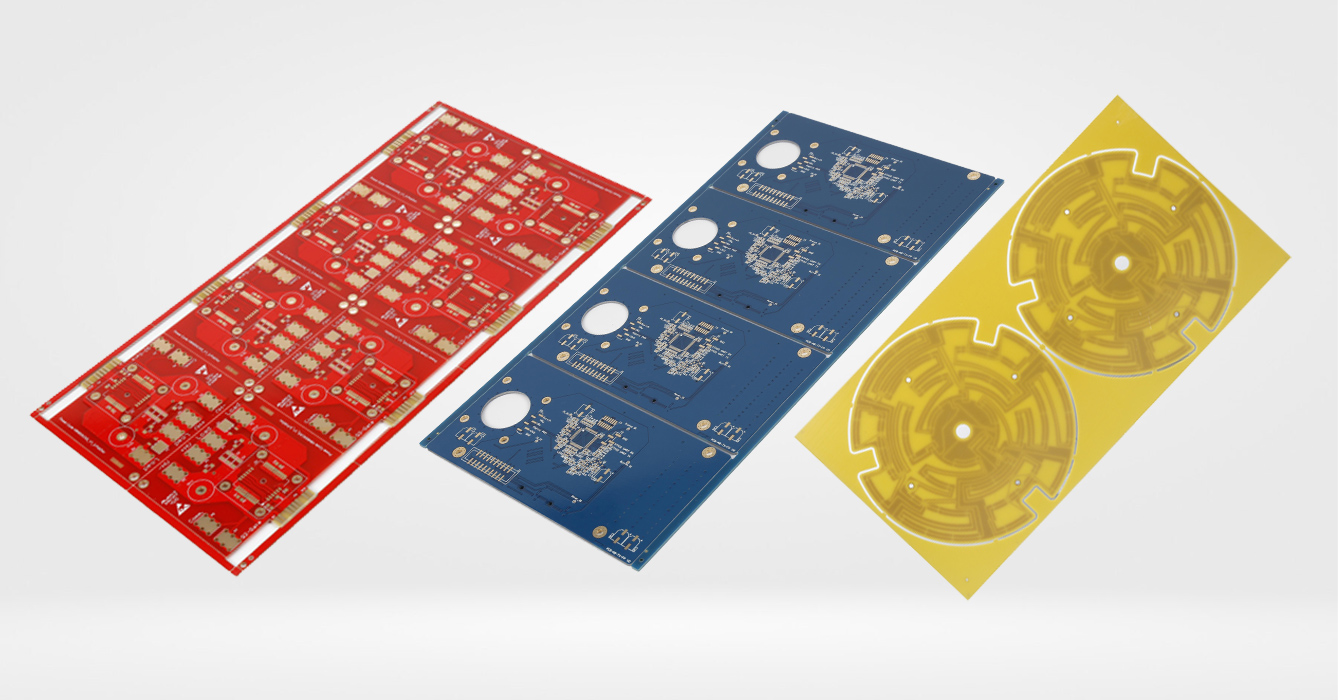

Flexible Production Scales: With scalable production capacities, factories can efficiently transition from small-batch prototypes (essential for R&D phases) to large-volume production, meeting tight deadlines for global clients.

FR4 Material Mastery

High-Quality FR4 Substrates: Factories source premium glass-reinforced epoxy (FR4) substrates, ensuring consistent dielectric properties, mechanical rigidity, and thermal stability. This material selection is critical for maintaining signal integrity and structural reliability in end applications.

Custom Material Formulations: For specialized needs, factories collaborate with material suppliers to develop FR4 variants with enhanced properties, such as flame resistance, low dielectric loss, or improved thermal conductivity, tailored to client specifications.

Technical Expertise and Innovation in Manufacturing

China FR4 PCB Manufacturing Factories combine traditional craftsmanship with cutting-edge technology to address the evolving demands of electronic design:

Precision Manufacturing Processes

Advanced Lamination: Controlled temperature and pressure lamination ensure strong bonding between layers, eliminating voids and ensuring uniform insulation. This step is vital for multi-layer boards where layer adhesion directly impacts electrical performance and durability.

High-Accuracy Etching and Drilling: Laser and mechanical drilling techniques achieve fine via diameters and tight trace tolerances, supporting high-density designs with miniaturized components. Etching processes are optimized to maintain trace integrity, critical for high-frequency signal transmission.

Surface Treatment Technologies: Factories offer diverse surface finishes, including ENIG (Electroless Nickel Immersion Gold), HASL (Hot Air Solder Leveling), and OSP (Organic Solderability Preservative), enhancing solderability, corrosion resistance, and compatibility with automated assembly processes.

R&D and Technological Advancement

Collaborative Design Support: Many factories provide engineering support, assisting clients with PCB layout optimization, material selection, and DFM (Design for Manufacturability) analysis to reduce production issues and improve performance.

Adoption of Smart Manufacturing: Integration of IoT sensors and data analytics in production lines enables real-time monitoring of processes, predictive maintenance, and continuous process improvement, ensuring consistent quality and efficiency.

Quality Control and Compliance Standards

China FR4 PCB Manufacturing Factories adhere to stringent quality protocols to meet global industry standards and client expectations:

Comprehensive Quality Assurance

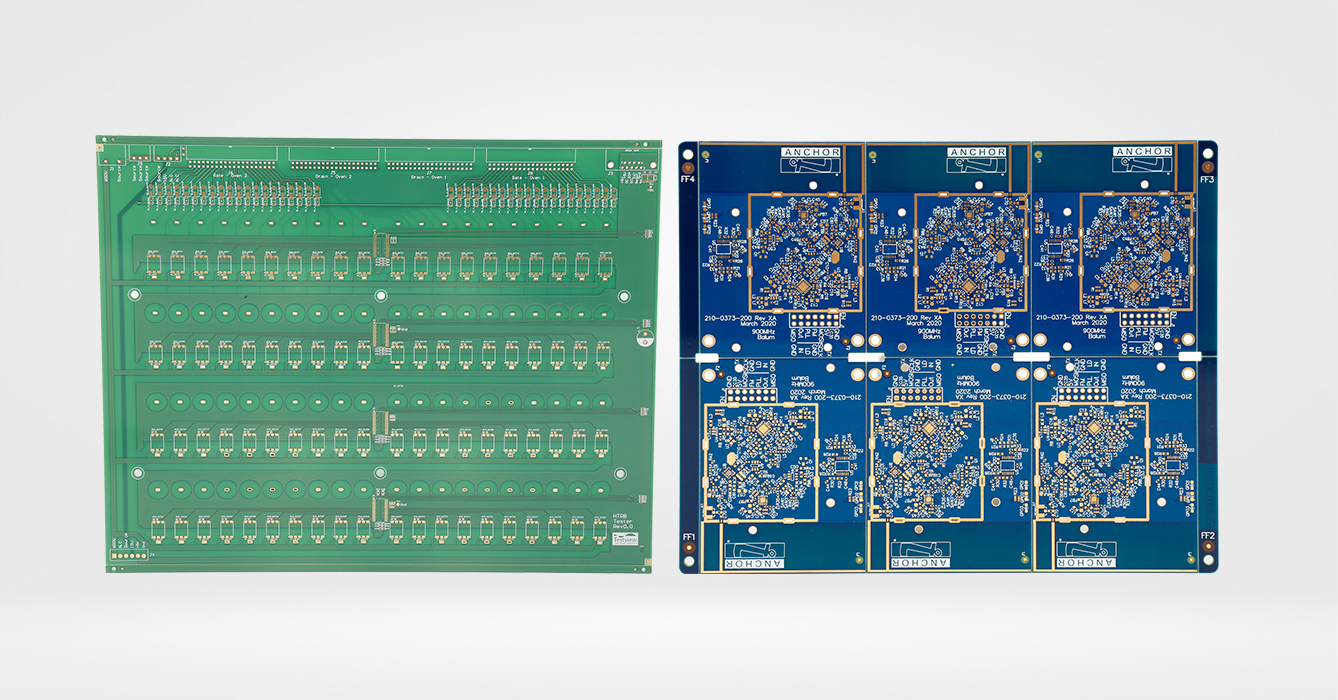

In-Line Inspection: Automated Optical Inspection (AOI) and X-ray testing detect defects such as misalignment, short circuits, or voids during production, ensuring issues are resolved before final assembly.

Electrical Testing: Each batch undergoes continuity, isolation, and impedance testing to verify electrical performance, with specialized testing for high-frequency boards to ensure signal integrity.

Environmental and Reliability Testing: Samples are subjected to thermal cycling, humidity, and vibration tests to validate performance in harsh operating conditions, ensuring compliance with industry standards like IPC, ISO, and RoHS.

International Certification Compliance

ISO Standards: Factories maintain certifications such as ISO 9001 (quality management) and ISO 14001 (environmental management), demonstrating commitment to quality and sustainability.

Industry-Specific Compliance: Many factories meet sector-specific standards, including IATF 16949 (automotive), ISO 13485 (medical), and MIL-STD (aerospace), ensuring their PCBs are suitable for regulated industries.

Industry Applications of China-Made FR4 PCBs

China FR4 PCB Manufacturing Factories supply boards for a wide range of applications, driven by their ability to meet diverse performance requirements:

Consumer Electronics

Smart Devices: Smartphones, tablets, and wearables rely on high-density FR4 PCBs for compact designs and reliable performance. Chinese factories’ scalability ensures timely supply for mass-market consumer products.

Home Appliances: FR4 PCBs power control systems in appliances like refrigerators, washing machines, and smart TVs, where durability and cost efficiency are key.

Industrial and Automotive Electronics

Industrial Automation: PCBs for PLCs, motor drives, and sensors require ruggedness and reliability, with China-made FR4 boards meeting the demands of factory environments with high vibration and temperature fluctuations.

Automotive Electronics: Factories produce FR4 PCBs for infotainment systems, ADAS (Advanced Driver-Assistance Systems), and powertrain controls, adhering to strict automotive quality standards for safety and longevity.

Communication and Medical Devices

Telecom Infrastructure: 5G base stations, routers, and network switches use low-loss FR4 PCBs for high-frequency signal transmission, with Chinese factories supporting the global rollout of next-generation communication networks.

Medical Equipment: FR4 PCBs in diagnostic devices, patient monitors, and portable medical tools meet stringent cleanliness and reliability standards, ensuring accuracy and patient safety.

Supply Chain Integration and Global Competitiveness

China FR4 PCB Manufacturing Factories benefit from a robust ecosystem that enhances their global competitiveness:

Integrated Supply Chains

Local Material Sourcing: Proximity to suppliers of FR4 substrates, copper foil, and chemicals reduces lead times and ensures material availability, even for large-volume orders.

Vertical Integration: Many factories integrate upstream and downstream processes, from material processing to final testing, streamlining production and enabling better quality control.

Global Market Reach

Export-Oriented Production: Factories cater to international clients, with logistics networks optimized for timely delivery to regions across Asia, Europe, North America, and beyond.

Cost-Efficiency: Economies of scale, efficient production processes, and competitive labor costs enable China-made FR4 PCBs to offer value without compromising quality, making them a preferred choice for global OEMs.

Sustainability and Environmental Responsibility

Modern China FR4 PCB Manufacturing Factories are increasingly prioritizing sustainability to align with global environmental goals:

Green Manufacturing Practices

Waste Reduction: Implementation of lean manufacturing reduces material waste, while recycling programs for copper, aluminum, and FR4 scrap minimize environmental impact.

Eco-Friendly Materials: Adoption of halogen-free FR4 substrates and low-VOC (Volatile Organic Compound) chemicals reduces harmful emissions, complying with global regulations like RoHS and REACH.

Energy Efficiency

Renewable Energy Adoption: Some factories integrate solar power and energy-efficient equipment to reduce carbon footprints, supporting global efforts to combat climate change.

Emission Control: Advanced filtration systems and wastewater treatment ensure compliance with environmental standards, protecting local ecosystems.

Conclusion

China FR4 PCB Manufacturing Factory plays a pivotal role in the global electronics supply chain, combining technical expertise, scalable production, and quality compliance to deliver high-performance FR4 PCBs for diverse applications. With advanced manufacturing infrastructure, a focus on innovation, and a commitment to sustainability, these factories meet the demands of industries ranging from consumer electronics to automotive and medical devices. As electronic designs continue to evolve toward miniaturization and higher performance, China’s FR4 PCB manufacturers are poised to remain at the forefront, driving progress through engineering excellence and global collaboration.

Keywords: China FR4 PCB Manufacturing Factory, FR4 PCB production, PCB manufacturing China, high-density PCB, electronics supply chain, green PCB manufacturing, global PCB supplier.

This article provides a comprehensive overview of China’s FR4 PCB manufacturing landscape, emphasizing technical capabilities, quality standards, and global impact while ensuring originality and alignment with SEO best practices.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB