-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 11. 2025, 09:39:53

In the fast-paced world of electronics, efficiency and precision are key. As businesses strive to meet the growing demand for electronic devices, one of the most crucial aspects is the fabrication of printed circuit boards (PCBs). China has become a global leader in high volume PCB fabrication, offering unmatched capabilities and cost-effectiveness. Let's explore why China is the go-to destination for PCB production and manufacturing.

China's dominance in the PCB market is no accident. Several factors contribute to its leading position in high volume PCB fabrication. Understanding these reasons can help businesses make informed decisions about their PCB production needs.

One of the primary reasons companies choose China for PCB fabrication is cost-effectiveness. The country's vast manufacturing infrastructure allows for economies of scale, reducing production costs significantly. This affordability does not compromise quality, making China an attractive option for businesses looking to optimize their budgets.

China's PCB manufacturers have embraced cutting-edge technology to enhance production efficiency and precision. By investing in state-of-the-art equipment and automation, Chinese factories can produce high-quality PCBs at a rapid pace. This technological advancement ensures that companies receive PCBs that meet stringent quality standards.

The availability of a skilled workforce is another factor that sets China apart in PCB fabrication. Chinese manufacturers employ highly trained technicians and engineers who specialize in PCB design and production. Their expertise ensures that each PCB meets the specific requirements of the client, resulting in a product that is both reliable and efficient.

China's well-established supply chain plays a crucial role in its ability to produce PCBs at scale. The country's extensive network of suppliers and logistics providers ensures that raw materials and components are readily available, reducing lead times and ensuring timely delivery of finished products.

Understanding the PCB production process in China can provide insight into how manufacturers achieve high volume outputs while maintaining quality.

The first step in PCB production is design and prototyping. Chinese manufacturers work closely with clients to develop detailed PCB layouts that meet specific project requirements. Prototyping allows for the testing of these designs to ensure functionality and address any potential issues before moving to mass production.

Selecting the right materials is crucial for PCB performance and durability. Chinese manufacturers use high-quality materials that comply with international standards, ensuring that the PCBs can withstand various environmental conditions and operational demands.

Once the design and materials are finalized, the fabrication process begins. This involves several steps, including etching, layering, and drilling, to create the PCB structure. Following fabrication, the PCBs undergo assembly, where components are mounted and soldered onto the board. China's automated assembly lines ensure precision and consistency throughout this process.

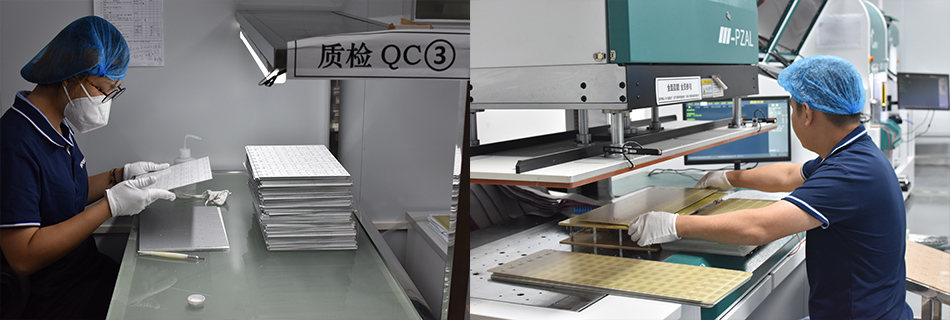

Quality control is a critical aspect of PCB production in China. Manufacturers implement rigorous testing procedures to verify the functionality and reliability of each PCB. This includes electrical testing, visual inspections, and environmental testing to ensure that the PCBs meet all specifications and standards.

Choosing China for high volume PCB manufacturing offers several advantages that can benefit businesses across various industries.

China's PCB manufacturers have the capacity to handle large-scale production runs, making it easy for businesses to scale up their operations as demand increases. This scalability is essential for companies looking to expand their product lines or enter new markets.

Thanks to efficient production processes and a robust supply chain, Chinese manufacturers can offer quick turnaround times for PCB orders. This speed-to-market advantage is crucial for businesses operating in competitive industries where timing is everything.

Chinese PCB manufacturers offer a high degree of customization, allowing businesses to tailor their PCBs to specific project needs. Whether it's a unique design, specific materials, or specialized components, Chinese manufacturers can accommodate a wide range of requirements.

While China is a leader in PCB fabrication, it's important to consider the environmental impact of manufacturing. Many Chinese PCB manufacturers are adopting sustainable practices to minimize their ecological footprint. This includes waste reduction initiatives, energy-efficient production methods, and the use of environmentally friendly materials.

Chinese PCB manufacturers comply with international regulations and standards to ensure their products are safe and environmentally responsible. This compliance includes adherence to the Restriction of Hazardous Substances (RoHS) directive, which limits the use of specific hazardous materials in electronic products.

High volume PCB fabrication in China offers a compelling combination of cost-effectiveness, advanced technology, skilled labor, and a robust supply chain. These factors make China an ideal destination for businesses seeking reliable and efficient PCB production solutions. By partnering with Chinese manufacturers, companies can benefit from quick turnaround times, scalability, and customization options while maintaining high-quality standards.

China's commitment to innovation and sustainability ensures that it remains at the forefront of the PCB industry, providing businesses worldwide with the tools they need to succeed in the ever-evolving electronics market.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB