-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 19. 2025, 08:45:04

In today's rapidly advancing technological landscape, choosing the right Printed Circuit Board (PCB) manufacturer can significantly impact the success of your electronic product. PCBs are the backbone of modern electronic devices, and selecting a reliable manufacturer is crucial for ensuring quality, reliability, and performance. This guide aims to help you understand the essential factors in choosing the right PCB manufacturer for your needs.

A Printed Circuit Board (PCB) mechanically supports and electrically connects electronic components using conductive tracks, pads, and other features etched from copper sheets laminated onto a non-conductive substrate. PCBs are found in almost every electronic device, from simple gadgets to complex machinery.

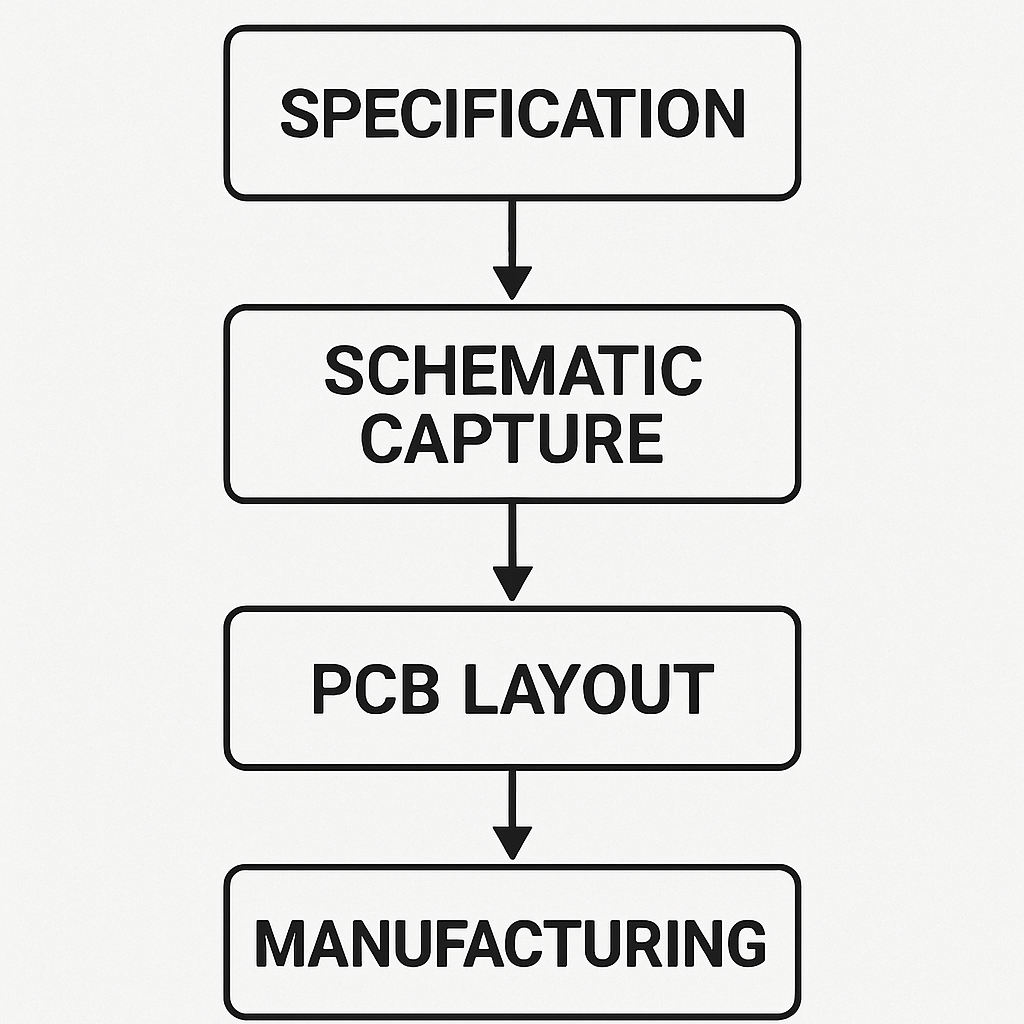

The design of a PCB is crucial because it affects the performance, cost, and reliability of the final product. A well-designed PCB ensures that the electronic components are properly connected and function as intended. It also minimizes the risk of errors and reduces manufacturing costs.

One of the first things to consider when choosing a PCB manufacturer is the quality standards they adhere to. Look for manufacturers that are certified with industry standards such as ISO 9001, IPC-A-610, and RoHS compliance. These certifications ensure that the manufacturer follows strict quality control processes, resulting in high-quality PCBs.

Experience matters in the PCB industry. Manufacturers with a long history in the field are more likely to have the expertise to handle complex designs and troubleshoot potential issues. Check the manufacturer's track record and client testimonials to gauge their experience and reliability.

Your project might have unique requirements that demand customization. A good PCB manufacturer should offer flexible solutions tailored to your specific needs. Whether it's a particular material, size, or design complexity, the manufacturer should be able to accommodate your requirements.

Time is often a critical factor in electronics manufacturing. Ensure the PCB manufacturer can meet your deadlines without compromising quality. Ask about their production lead times and if they offer expedited services for urgent projects.

Some PCB manufacturers offer design and prototyping services, allowing you to test your PCB design before full-scale production. This can save you time and money by identifying and correcting design flaws early in the process.

If you need PCB assembly services, check if the manufacturer offers in-house assembly. This can streamline the production process and reduce the risk of errors. Ask about their assembly capabilities, including surface mount technology (SMT) and through-hole technology.

A reliable PCB manufacturer should have robust testing and quality assurance processes in place. This includes in-circuit testing, functional testing, and inspection to ensure each PCB meets your specifications and performs reliably.

While cost is an important factor, it should not be the sole determinant when choosing a PCB manufacturer. Cheaper options might compromise on quality, leading to potential failures and increased costs in the long run. Aim to find a balance between cost and quality to ensure the best value for your investment.

Be aware of hidden costs that might not be immediately apparent. These can include setup fees, tooling costs, and additional charges for expedited services. Request a detailed quote from the manufacturer, including all potential costs, to avoid surprises.

Effective communication with your PCB manufacturer is essential for a smooth production process. Evaluate their customer service and support systems to ensure they are responsive and can address your concerns promptly.

Technical support is crucial, especially if you encounter design or manufacturing challenges. Choose a manufacturer that offers comprehensive technical support and is willing to work with you to resolve issues quickly.

Choosing the right PCB manufacturer is a critical decision that can affect the success of your electronic product. By considering factors such as quality standards, experience, customization options, and cost, you can make an informed choice that aligns with your project's needs. Remember that investing in a reliable manufacturer can save you time, money, and headaches in the long run. With the right partner, you can bring your electronic innovations to life with confidence.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB