-

- PCB TYPE

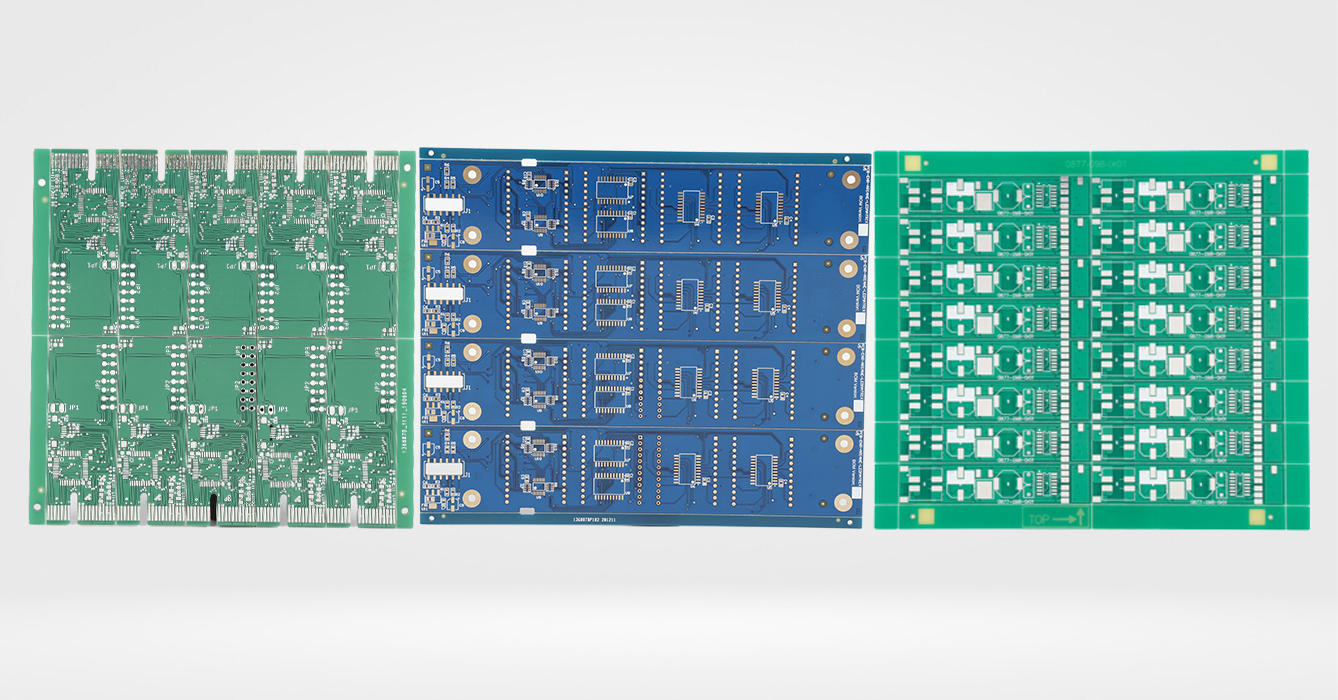

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 14. 2025, 16:30:51

In the landscape of printed circuit board (PCB) materials, the Composite Epoxy Material-3 CEM3 Specification defines a unique class of substrates engineered to bridge the gap between cost-sensitive and high-performance applications. CEM3 belongs to the family of composite epoxy materials (CEM), which blend epoxy resins with reinforcing materials to deliver tailored mechanical, electrical, and thermal properties. Unlike FR4—its more ubiquitous counterpart—CEM3 is designed for applications where a balance of processability, flame resistance, and affordability takes precedence over extreme performance. This article explores the CEM3 specification, its material composition, key characteristics, manufacturing considerations, and ideal applications, highlighting how it serves as a versatile alternative in the PCB ecosystem.

The Composite Epoxy Material-3 CEM3 Specification is governed by industry standards (such as IPC-4101) that outline its core attributes: a composite substrate composed of epoxy resin, glass fiber reinforcement, and a flame-retardant system. The "CEM3" designation distinguishes it from other CEM variants (e.g., CEM1, CEM2) through its specific reinforcement and resin formulation, which prioritize ease of manufacturing and consistent performance in moderate operating conditions.

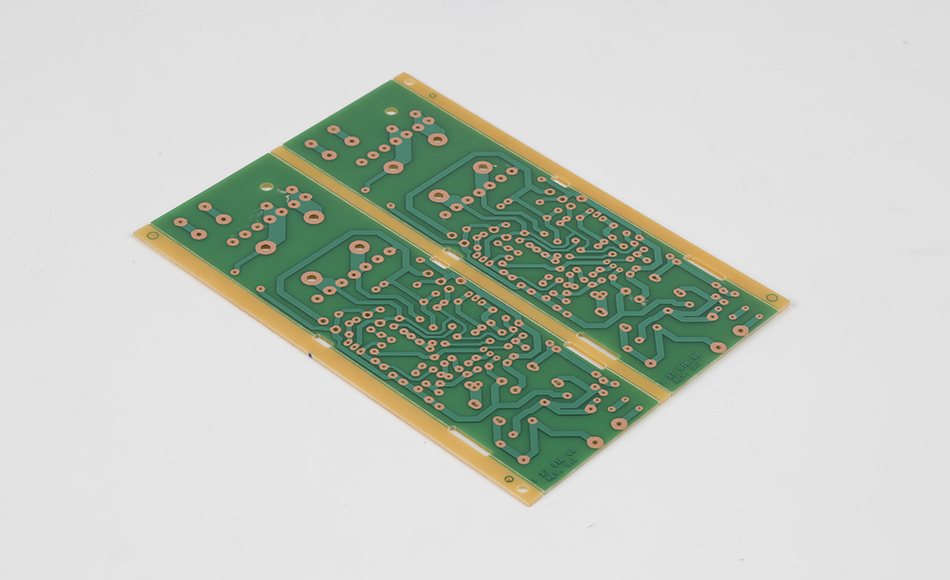

CEM3 is defined by its structure: a central core of non-woven glass fiber mat impregnated with epoxy resin, layered with woven glass fabric on both sides. This configuration enhances mechanical stability while maintaining flexibility in processing—key traits that set it apart from FR4 (which uses woven glass throughout) and CEM1 (which uses paper reinforcement, limiting thermal resistance). The specification mandates flame retardancy (typically meeting UL94 V-0) and electrical insulation properties suitable for general-purpose electronics, ensuring it meets safety and functional benchmarks across industries.

The CEM3 specification hinges on a deliberate blend of materials, each contributing to its balanced performance:

Epoxy Resin Matrix: The binding agent in CEM3 is a thermosetting epoxy resin, chosen for its strong adhesion, chemical resistance, and ability to cure into a rigid, insulating structure. Unlike the high-performance epoxy formulations used in FR4, CEM3’s resin is optimized for cost-effectiveness and flow during manufacturing, ensuring uniform impregnation of reinforcing materials.

Reinforcement Layers: CEM3’s reinforcement is a hybrid of non-woven glass mat (core) and woven glass fabric (outer layers). The non-woven mat—composed of randomly oriented glass fibers—enhances resin retention and reduces manufacturing complexity, while the woven fabric adds mechanical strength and dimensional stability. This combination strikes a balance between rigidity (critical for component mounting) and processability (simplifying cutting and drilling).

Flame Retardants: To meet the CEM3 specification’s flame resistance requirements, additives (such as brominated compounds or phosphorus-based alternatives) are integrated into the epoxy resin. These additives suppress combustion by forming a protective char layer when exposed to heat, ensuring compliance with global safety standards for electronics.

Copper Cladding: Thin copper foils are bonded to one or both sides of the CEM3 substrate to form conductive traces. The specification dictates minimum adhesion strength between copper and the epoxy matrix to ensure reliability during thermal cycling and assembly.

This composite structure enables CEM3 to deliver consistent performance without the higher costs associated with fully woven glass substrates like FR4.

The Composite Epoxy Material-3 CEM3 Specification emphasizes traits that make it suitable for general-purpose applications, avoiding over-engineering for niche demands:

Mechanical Stability: CEM3 offers sufficient rigidity to support component mounting and resist warping during manufacturing, though it is slightly more flexible than FR4. This flexibility simplifies forming and cutting, making it ideal for low-volume or custom PCB designs.

Electrical Insulation: The epoxy matrix provides reliable insulation between copper traces, preventing signal leakage in low-to-moderate frequency circuits (up to several hundred megahertz). While not optimized for high-speed signals (unlike low-dielectric materials), it meets the needs of most consumer and industrial electronics.

Flame Resistance: A cornerstone of the specification, CEM3’s flame-retardant formulation ensures it self-extinguishes quickly when exposed to fire, reducing risks in enclosed environments like homes, offices, or vehicles.

Thermal Performance: CEM3 handles moderate temperatures effectively, making it suitable for applications where operating conditions remain below extreme thresholds (e.g., consumer devices, office equipment). It resists softening or delamination under sustained heat, though it is outperformed by high-temperature FR4 in industrial ovens or engine bays.

Cost-Effectiveness: By using non-woven glass in its core, CEM3 reduces raw material costs compared to fully woven substrates. Its simplified manufacturing process further lowers production expenses, making it a budget-friendly alternative for cost-sensitive projects.

The CEM3 specification is designed to align with standard PCB manufacturing processes, with subtle adjustments to account for its unique composition:

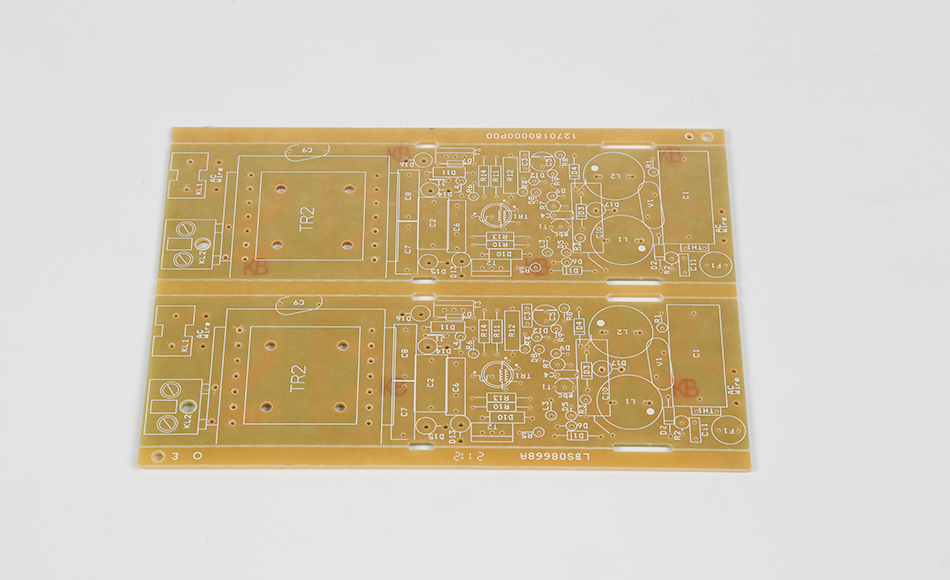

Prepreg Production: CEM3 prepreg (partially cured resin-impregnated reinforcement) is manufactured by saturating non-woven glass mat and woven glass fabric with epoxy resin. The non-woven core absorbs resin more readily than woven fabric, reducing processing time and ensuring uniform impregnation.

Lamination: Layers of prepreg and copper foil are stacked and pressed under heat to cure the epoxy, forming a solid laminate. CEM3 requires lower lamination pressure than FR4 due to its non-woven core, reducing energy consumption and equipment wear.

Drilling and Routing: The hybrid reinforcement (non-woven core + woven outer layers) allows for clean drilling with standard carbide tools, minimizing burring or fiber pull-out. This simplifies post-processing and reduces the risk of electrical shorts from debris.

Etching and Finishing: CEM3’s copper cladding adheres reliably to the epoxy matrix, enabling consistent etching of circuit traces. It works with standard solder masks and surface finishes (e.g., HASL, OSP), ensuring compatibility with existing assembly lines.

These manufacturing advantages make CEM3 accessible to PCB producers of all scales, from small workshops to large factories, without requiring specialized equipment.

CEM3’s balanced properties, as defined by its specification, make it ideal for applications where extreme performance is unnecessary:

Consumer Electronics: Devices like televisions, audio systems, and small appliances use CEM3 for their control boards. These applications demand reliability in moderate temperatures and low-frequency signals—areas where CEM3 excels without the cost of FR4.

Office Equipment: Printers, scanners, and fax machines rely on CEM3 for their internal circuitry. Its flame resistance and mechanical stability ensure safe, long-term operation in office environments.

Low-Power Industrial Controls: Simple industrial sensors, relay modules, and basic automation controllers use CEM3 to balance cost and durability. It withstands dust and minor vibrations without compromising performance.

Automotive Interior Electronics: Cabin systems (e.g., infotainment displays, climate controls) use CEM3 for its flame resistance and compatibility with standard manufacturing. It performs reliably in the moderate temperatures of vehicle interiors, though underhood components require more heat-resistant materials.

Educational and Prototyping: CEM3 is a popular choice for student projects and low-volume prototypes, where its affordability and ease of processing enable experimentation without excessive cost.

In each case, CEM3 meets the application’s requirements without the unnecessary complexity of higher-performance materials.

The CEM3 specification positions it uniquely relative to other common substrates:

vs. FR4: FR4 uses woven glass throughout, offering higher mechanical strength and thermal resistance, making it suitable for high-power or high-frequency applications. CEM3, with its non-woven core, is more cost-effective and easier to process but less robust in extreme conditions.

vs. CEM1: CEM1 uses paper reinforcement, which limits its thermal and moisture resistance. CEM3’s glass reinforcement makes it more durable, extending its use to slightly harsher environments (e.g., humid industrial settings).

vs. Metal-Core PCBs: Metal-core substrates excel at heat dissipation but are more expensive and conductive (requiring additional insulation). CEM3 is preferable for low-heat applications where cost and electrical insulation are prioritized.

This positioning makes CEM3 a "middle ground" material, filling gaps where FR4 is overkill and CEM1 is insufficient.

The Composite Epoxy Material-3 CEM3 Specification adheres to global standards to ensure consistency and safety:

IPC-4101: This key standard classifies CEM3 under the "composite epoxy materials" category, defining requirements for resin content, reinforcement type, and performance benchmarks (e.g., dielectric strength, flexural strength).

UL94 Flame Rating: CEM3 must meet UL94 V-0, confirming its self-extinguishing properties and limiting flame spread—a critical requirement for consumer and industrial safety.

RoHS and REACH: Modern CEM3 formulations comply with these regulations, restricting hazardous substances (e.g., lead, certain halogens) to meet environmental and health standards in global markets.

Automotive Standards: For automotive applications, CEM3 may comply with IATF 16949, ensuring quality and reliability in vehicle electronics.

These standards provide confidence to manufacturers and designers, ensuring CEM3 performs consistently across suppliers and applications.

Challenges and Limitations of CEM3

While versatile, CEM3 has limitations outlined in its specification that guide its appropriate use:

High-Temperature Constraints: CEM3 is not designed for sustained exposure to extreme heat, making it unsuitable for industrial ovens, power amplifiers, or underhood automotive components.

High-Frequency Limitations: Its dielectric properties degrade at very high frequencies (above 1 GHz), limiting use in 5G infrastructure, radar, or high-speed data links.

Mechanical Strength: While sufficient for most applications, CEM3’s non-woven core reduces its rigidity compared to FR4, making it less ideal for heavy component mounting or high-vibration environments.

Understanding these limitations ensures CEM3 is used where it adds the most value—avoiding over-application in scenarios requiring specialized materials.

The CEM3 specification continues to evolve to meet modern demands:

Sustainable Formulations: Manufacturers are developing CEM3 with bio-based epoxy resins and recycled glass fibers, reducing environmental impact while maintaining performance.

Halogen-Free Options: To align with stricter environmental regulations, halogen-free flame retardants (e.g., phosphorus-based) are replacing traditional brominated additives, expanding CEM3’s use in eco-conscious markets.

Enhanced Thermal Resistance: Modified epoxy formulations are extending CEM3’s temperature range, allowing it to serve in slightly harsher environments (e.g., outdoor sensors) without sacrificing cost advantages.

These advancements ensure CEM3 remains relevant in a market increasingly focused on sustainability and versatility.

The Composite Epoxy Material-3 CEM3 Specification defines a substrate that excels in balancing performance, cost, and processability—traits that make it a valuable asset in the PCB ecosystem. By leveraging a hybrid reinforcement structure and optimized epoxy formulation, CEM3 meets the needs of consumer electronics, office equipment, and low-power industrial systems, where extreme performance is unnecessary. Its compliance with global standards ensures reliability and safety, while its manufacturing efficiency makes it accessible to producers of all scales. As sustainability and cost pressures drive innovation, CEM3 continues to adapt, solidifying its role as a practical, versatile alternative to more specialized PCB materials. For designers and manufacturers seeking a middle ground between affordability and functionality, CEM3 remains an indispensable choice.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB