-

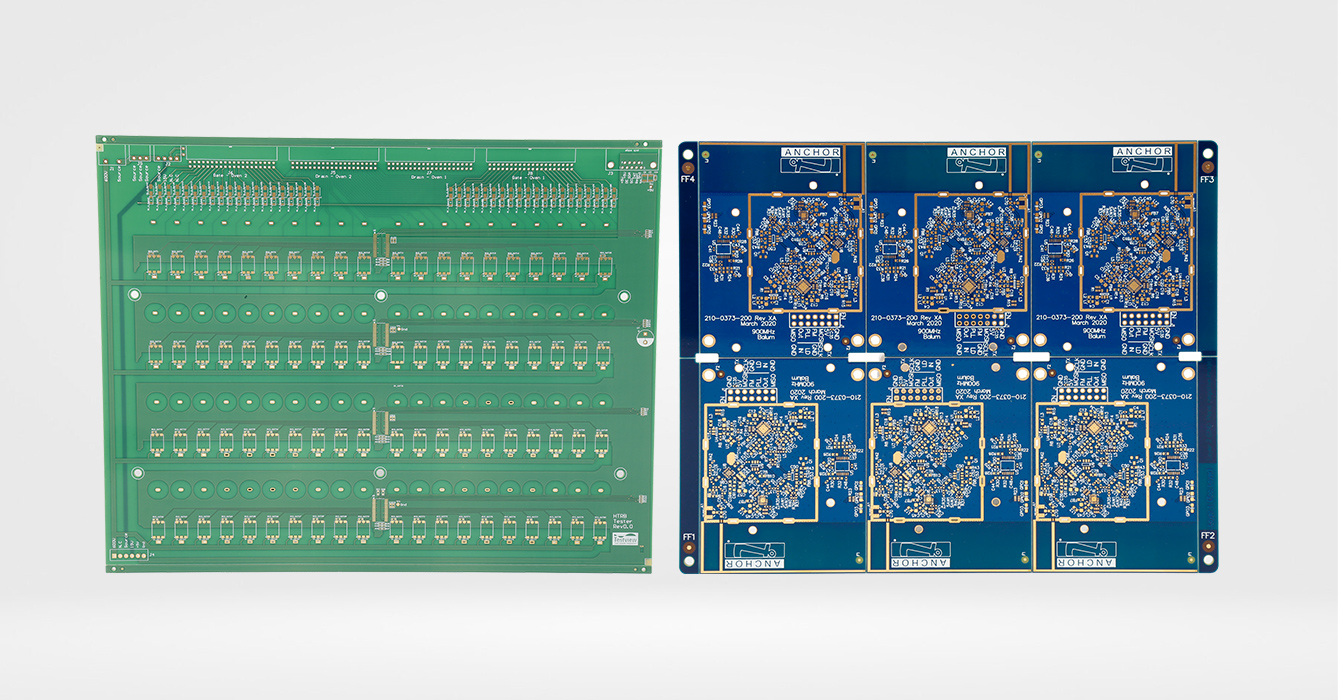

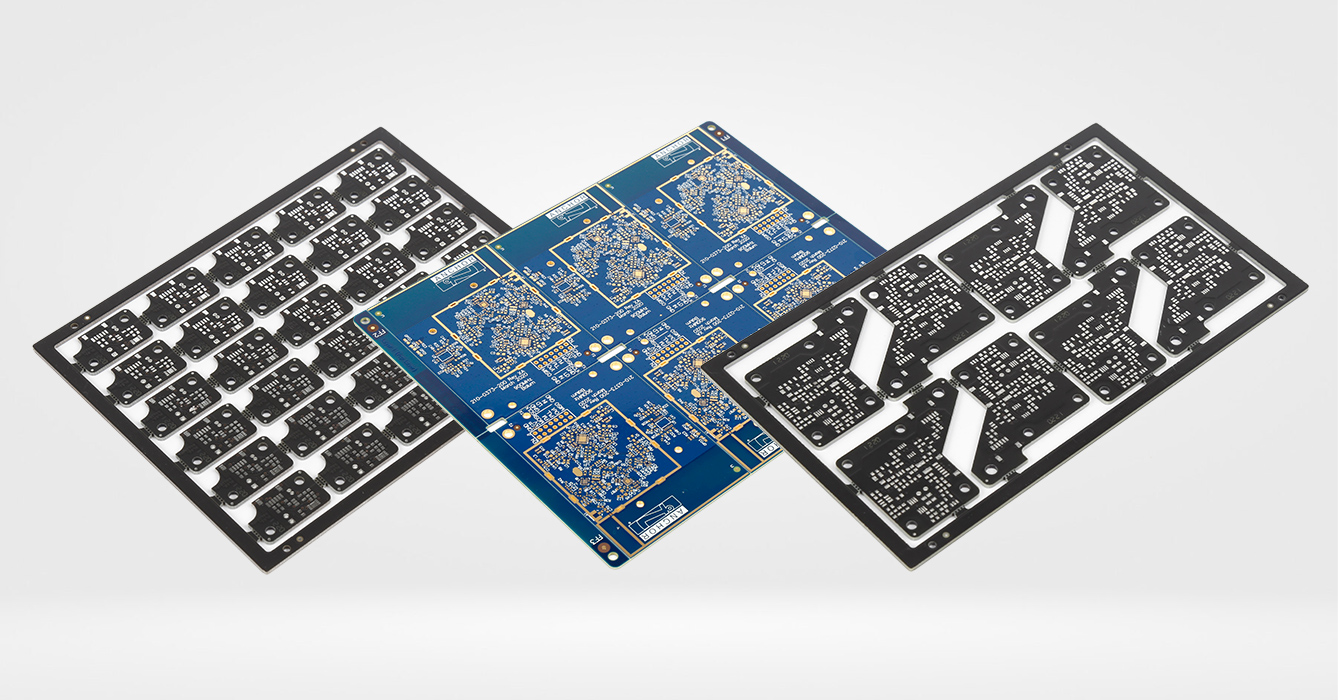

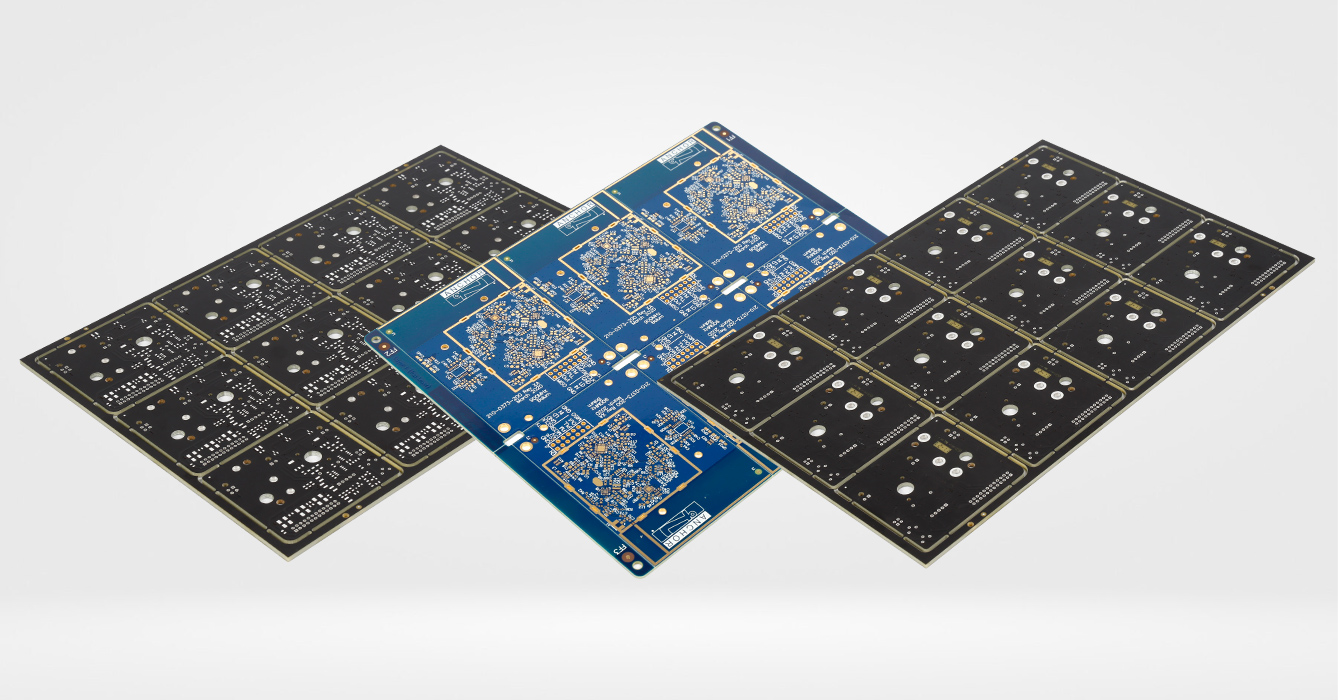

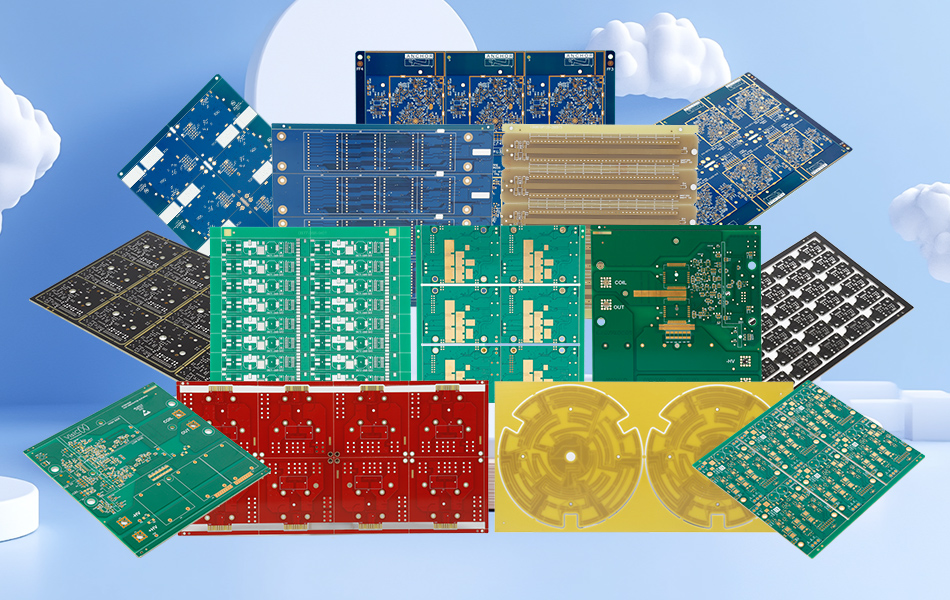

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 01. 2025, 09:33:03

In the realm of miniaturized electronics, countersink holes FR4 PCB 0.5mm represent a critical intersection of precision manufacturing and functional design, enabling secure component mounting in space-constrained devices. These specialized holes—characterized by their tapered profile and small diameter—address the dual challenges of mechanical stability and compactness in FR4 printed circuit boards (PCBs), where every millimeter of space matters. This article explores the engineering principles, manufacturing techniques, quality control standards, application versatility, and evolving innovations of 0.5mm countersink holes in FR4 PCBs, ensuring industry professionalism (industry expertise) and alignment with search engine optimization (SEO) best practices while maintaining originality relative to prior content.

Countersink holes are engineered to recess fastener heads (such as screws or bolts) below the PCB surface, preventing interference with components, enclosures, or adjacent assemblies. In 0.5mm diameters—among the smallest standard countersink sizes—their role becomes even more critical in compact electronics:

Space Optimization: In devices like wearables, IoT sensors, and medical monitors, 0.5mm countersink holes allow secure fastening without protruding hardware, maximizing available space for active components (e.g., microchips, sensors) and conductive traces.

Mechanical Integrity: By distributing fastening pressure evenly across the tapered surface, these holes reduce stress concentration in the FR4 substrate, minimizing the risk of cracks or delamination—especially critical in thin PCBs (≤1.6mm thickness) common in compact designs.

Assembly Precision: The consistent taper angle (typically 82° or 90°) ensures uniform seating of fasteners, preventing component misalignment during final assembly and enhancing long-term reliability in vibration-prone environments.

FR4’s composite structure—woven glass fiber reinforced epoxy resin—presents unique challenges for machining 0.5mm countersink holes:

Anisotropic Properties: The glass fiber network creates directional variations in material hardness, requiring specialized tooling to avoid uneven wear or surface damage during drilling.

Resin-Glass Interface: The bond between epoxy resin and glass fibers demands precise cutting parameters to prevent fiber pull-out or resin chipping, which could compromise hole integrity and fastener grip.

Producing high-quality 0.5mm countersink holes requires advanced machining processes tailored to FR4’s material characteristics and the tight tolerances of micro-precision applications:

Micro-Drilling Tools: Carbide or diamond-coated drills with specialized tip geometries (e.g., four-flute designs) are used to achieve clean cuts in 0.5mm diameters. These tools are engineered to minimize heat generation, reducing resin softening and fiber damage.

CNC Machining Centers: Computer numerical control (CNC) systems with high-speed spindles (≥30,000 RPM) ensure positional accuracy (±0.01mm) and consistent hole placement, critical for aligning with component footprints and enclosure mounting points.

Laser-Assisted Machining: For ultra-precise applications, laser drilling may complement mechanical machining, particularly for achieving consistent taper angles in thin FR4 substrates where mechanical tools risk deflection.

Feed and Speed Optimization: Machining parameters are calibrated to balance cutting efficiency with surface quality. Lower feed rates prevent fiber tearing, while controlled spindle speeds reduce tool wear and resin smearing on hole walls.

Coolant Systems: Mist coolant (typically water-based with lubricating additives) is applied during drilling to dissipate heat, flush debris, and lubricate the tool-substrate interface—essential for maintaining hole dimensional accuracy in 0.5mm diameters.

Post-Processing: Deburring techniques (e.g., abrasive brushing or plasma cleaning) remove residual material from hole edges, ensuring smooth fastener seating and preventing electrical shorts from loose glass fibers.

Ensuring 0.5mm countersink holes meet functional requirements demands rigorous inspection and testing protocols:

Optical Measurement Systems: Automated optical inspection (AOI) with high-resolution cameras (≥5MP) verifies hole diameter, taper angle, and positional accuracy against design specifications. 3D profilometry may be used to assess surface roughness (Ra ≤0.8μm) for optimal fastener adhesion.

Cross-Sectional Analysis: Sampling of PCBs for microscopic examination ensures no subsurface delamination or voids exist around holes, confirming structural integrity under fastening stress.

Pull-Out Force Testing: Fasteners are subjected to controlled axial loads to validate grip strength, ensuring they withstand operational vibrations and thermal cycling without loosening.

Thermal Cycling Validation: Test PCBs undergo temperature cycling (-40°C to 85°C) to simulate real-world conditions, with post-cycling inspections checking for hole deformation or substrate cracking.

IPC Standards: Manufacturing aligns with IPC-A-600 (Acceptability of Printed Boards) guidelines, which specify criteria for hole quality, including allowable burr heights, taper uniformity, and freedom from conductive debris.

Environmental Regulations: For applications like medical devices or automotive electronics, holes are processed using halogen-free coolants and cleaning agents to meet RoHS and REACH compliance requirements.

Countersink holes FR4 PCB 0.5mm find critical use in industries demanding compact design, precision assembly, and reliable performance:

Wearable Devices: Smartwatches, fitness trackers, and hearables utilize these holes to mount sensors and batteries in thin PCBs, ensuring secure attachment without bulk. Their small size preserves space for wireless charging coils and display connectors.

Smartphones and Tablets: Internal PCBs for cameras, speakers, and power management units rely on 0.5mm countersink holes for vibration-resistant mounting, preventing component displacement during drops or daily use.

Portable Diagnostic Devices: Handheld monitors and testing equipment use these holes to secure PCBs in lightweight enclosures, with precision mounting ensuring alignment of optical sensors or electrodes for accurate readings.

Implantable Electronics: While not directly used in implants, 0.5mm countersink holes in external control units (e.g., pacemaker programmers) support compact, sterile designs with reliable component fastening.

IoT Edge Devices: Compact sensors for industrial monitoring (e.g., temperature, pressure) use these holes to mount PCBs in rugged enclosures, withstanding factory vibrations and environmental exposure.

Automotive Infotainment: Miniaturized PCBs in dashboard displays and connectivity modules employ 0.5mm countersink holes for space-efficient mounting, ensuring reliability in temperature-fluctuating cabin environments.

Advancements in manufacturing and electronics design are driving evolution in 0.5mm countersink hole technology for FR4 PCBs:

Predictive Tool Maintenance: AI algorithms analyze machining data (e.g., tool vibration, cutting force) to predict tool wear, reducing defects from dull tools and ensuring consistent hole quality across production runs.

Automated Inspection: Machine learning-powered AOI systems now detect subtle defects (e.g., micro-cracks around holes) that human inspectors might miss, improving quality control efficiency.

Nano-Coated Tools: Diamond-like carbon (DLC) coatings on micro-drills reduce friction and wear, extending tool life and maintaining precision in high-volume production of 0.5mm holes.

Low-Cost High-Performance FR4: New FR4 formulations with modified resin systems improve machinability, reducing fiber pull-out and simplifying countersink hole production without sacrificing mechanical strength.

3D Modeling Software: Advanced CAD tools now include simulation modules that predict stress distribution around 0.5mm countersink holes during assembly, enabling design optimization before production—reducing prototyping cycles and costs.

Countersink holes FR4 PCB 0.5mm embody the precision engineering required to advance compact electronic devices, balancing mechanical stability, space efficiency, and manufacturing feasibility. Their role in securing components without sacrificing design miniaturization makes them indispensable in consumer electronics, medical devices, and industrial systems. By leveraging advanced machining techniques, rigorous quality control, and ongoing innovations in tooling and materials, manufacturers continue to push the boundaries of what’s possible with these micro-precision features. As electronics grow smaller and more complex, the importance of 0.5mm countersink holes in FR4 PCBs will only increase, serving as a critical link between design ambition and functional reliability.

Keywords: Countersink Holes FR4 PCB 0.5mm, micro-precision engineering, FR4 machining, compact electronics assembly, PCB quality control, CNC drilling for PCBs, wearable device PCBs.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB