-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 04. 2025, 19:41:31

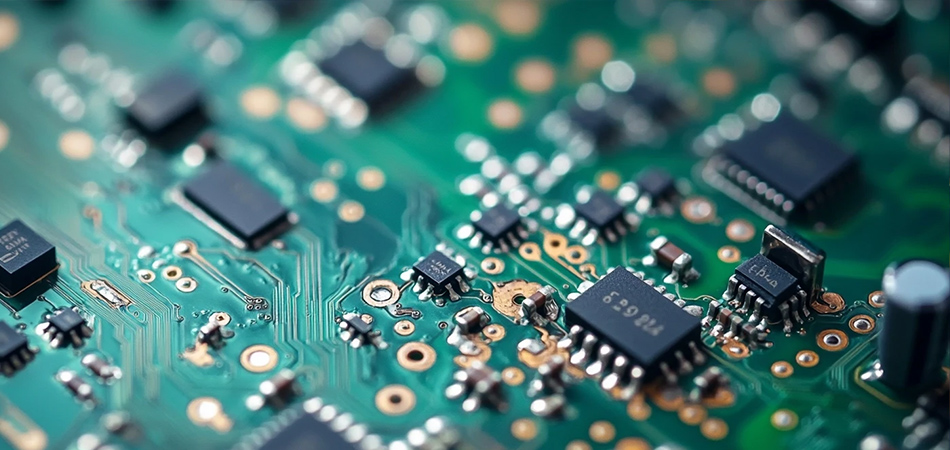

Custom PCB Design & Fabrication delivers tailored circuit boards for specialized electronic needs, outperforming generic PCBs in industries like industrial automation, medical devices, and consumer electronics. By aligning with specific performance, environmental, and form-factor requirements, custom solutions ensure efficiency, reliability, and cost-effectiveness in complex applications.

Requirements Analysis: Defines functional needs (component types, signal paths), environmental constraints (temperature, vibration), form-factor limits, and regulatory standards (IPC-2221, ISO 13485).

Schematic Design: Translates requirements into electrical diagrams, with component selection and circuit simulation to validate functionality (e.g., stable power distribution).

Layout Design: Optimizes component placement (thermal management, noise isolation) and trace routing (controlled impedance for high-speed signals). Integrates ground/power planes to reduce noise.

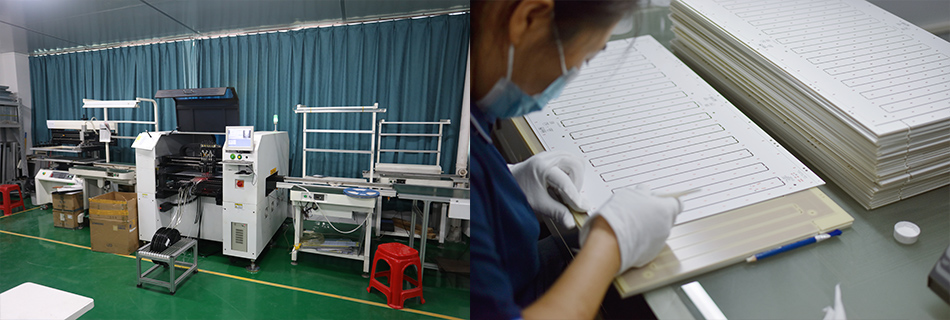

DFM Validation: Ensures manufacturability via design rule checks and prototype testing, preventing costly errors in mass production.

Materials: Substrates (FR-4 for general use, high-Tg for high temperatures, PTFE for RF) and copper thickness (0.5oz–4oz) are chosen for current and environment needs. Surface finishes (HASL, ENIG, OSP) balance solderability and cost.

Processes: Layer lamination, precision drilling (including micro-vias for HDI), and etching (subtractive/additive) shape the PCB. Advanced techniques like laser drilling enable miniaturization.

Quality Control: AOI, electrical testing (continuity/isolation), and thermal/mechanical checks ensure compliance with performance standards.

Industrial Automation: Ruggedized PCBs with thick copper (2oz–4oz) and conformal coating resist extreme temperatures and vibration, ensuring reliability in factory settings.

Medical Devices: Low-noise designs with shielded traces and biocompatible materials meet ISO 13485 standards, critical for imaging and life-support equipment.

Aerospace/Defense: Radiation-hardened materials and MIL-STD compliance (vibration, temperature) support satellite and avionics systems.

Consumer Electronics: HDI designs with micro-vias enable compact, high-performance devices like foldable phones and wearables.

Key criteria include:

Industry expertise and certifications (AS9100, ISO 13485).

Manufacturing capabilities (layer count, HDI, flexible substrates).

Robust supply chains for component sourcing and shortage mitigation.

Transparent communication and post-delivery support.

High-Speed Design: Low-loss materials enable 100Gbps+ data transmission in networking.

Miniaturization: HDI and 3D packaging pack more functionality into smaller footprints.

Sustainability: Recycled materials and lead-free processes reduce environmental impact.

Smart Manufacturing: AI and digital twins optimize design and production efficiency.

Custom PCB Design & Fabrication is pivotal for innovative electronics, balancing performance and adaptability across industries. By partnering with skilled providers and leveraging emerging technologies, manufacturers can deliver reliable, cutting-edge solutions that meet evolving market demands.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB