-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 07. 2025, 10:24:51

Custom SMT Stencils Manufacturing is a specialized service that designs and produces surface-mount technology (SMT) stencils tailored to the unique requirements of specific PCB designs, production volumes, and component types. Unlike off-the-shelf standard stencils, custom solutions address the challenges of non-standard PCB layouts, niche components, and industry-specific constraints—from high-temperature automotive environments to space-constrained wearable devices. As electronics designs grow more diverse (e.g., flexible PCBs, mixed-component boards), custom SMT stencils have become essential for ensuring solder paste accuracy, reducing assembly defects, and aligning with production goals. This article explores the core workflow of custom SMT stencils manufacturing, key customization strategies, industry-specific applications, and how it drives efficiency in specialized electronics production.

Custom stencil production follows a collaborative, design-driven workflow to ensure alignment with client needs:

- Needs Diagnosis & Design Intake: Manufacturers start by gathering client requirements—PCB Gerber files, component BOM, solder paste specifications, and production volume. Engineers analyze these to identify critical factors: e.g., a PCB with both BGA and 0201 passives requires aperture customization for each component type.

- Collaborative Aperture Engineering: Using CAD tools, engineers co-design aperture patterns with clients. This includes adjusting aperture size (to control paste volume), shape (e.g., dog-bone apertures for connectors), and arrangement (to avoid shadowing on dense PCBs). For flexible PCBs, stencil flexure is also optimized to prevent warping during printing.

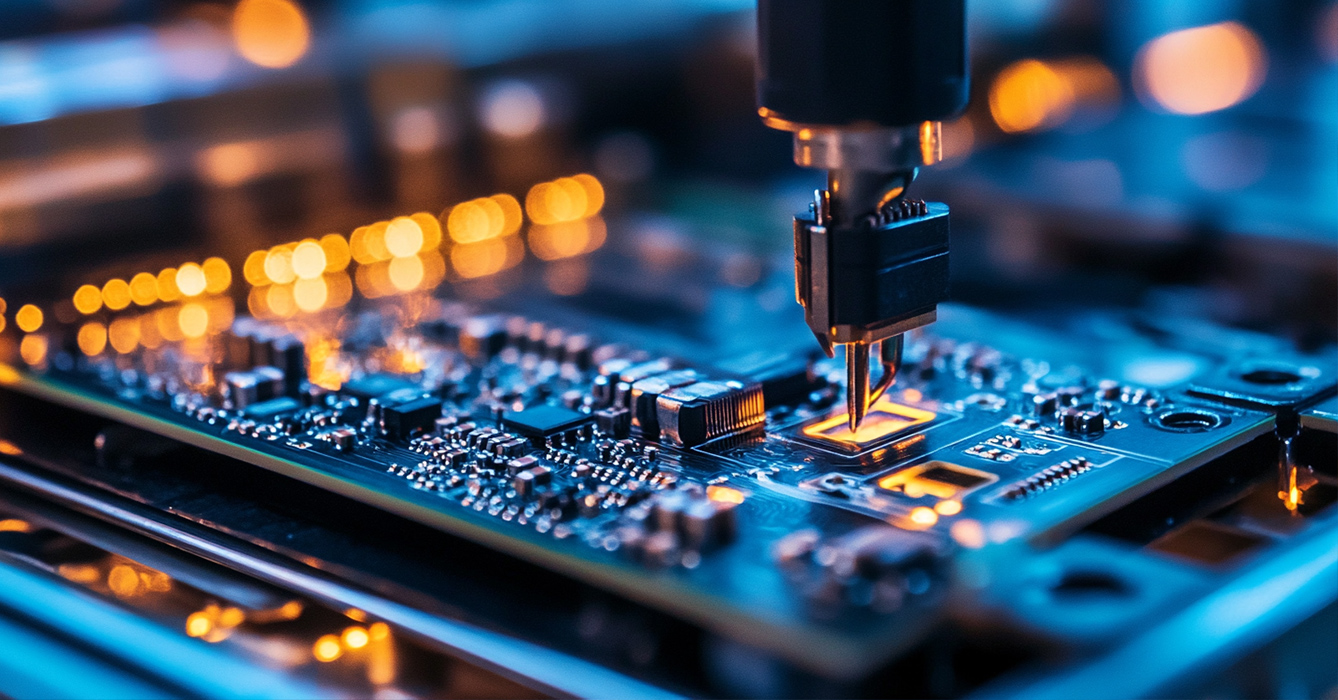

- Process Selection & Prototyping: Based on design complexity, manufacturers choose the best fabrication process (laser cutting, electroforming, or chemical etching) and produce a prototype stencil. Clients test this prototype in their production line to validate paste transfer, with adjustments made before full production.

- Production & Quality Validation: The final stencil is manufactured with premium materials and surface treatments, then inspected via 3D metrology and AOI to ensure compliance with the approved design. Traceability documentation (material certificates, inspection reports) is provided for regulatory compliance.

Custom manufacturers address the challenges of mixed-component PCBs by tailoring apertures to each part:

- Fine-Pitch ICs: Narrow, precise apertures (with aspect ratios optimized for paste release) prevent bridging between leads.

- Large Thermal Pads: Stepped or split apertures ensure uniform paste coverage without excessive solder buildup, reducing the risk of delamination.

- Odd-Form Components: Custom-shaped apertures match irregular pad geometries (e.g., for sensors or connectors), ensuring consistent paste deposition.

For non-standard production setups, stencils are customized in form and material:

- Flexible Stencils: Made from thin stainless steel or polyimide for curved or flexible PCBs, preventing damage during printing.

- Modular Stencils: Sectional designs for large PCBs (e.g., automotive dashboards) that won’t fit standard printing machines, enabling easier handling and alignment.

- High-Temp Materials: Heat-resistant coatings for stencils used with lead-free or high-temperature solder pastes in industrial applications.

Industrial PCBs (e.g., for factory automation controllers) often have large power components and small signal ICs. Custom stencils use split apertures for power pads and fine apertures for signal components, ensuring reliable performance in harsh industrial environments with temperature swings and vibration.

Wearables (e.g., smartwatches, fitness trackers) use flexible PCBs with miniaturized components. Custom stencils are thin, flexible, and feature micro-apertures for 01005 passives, while aperture spacing is optimized to avoid paste smearing on curved surfaces during printing.

Aerospace PCBs require stencils that meet strict military standards (e.g., MIL-PRF-32432). Custom manufacturers produce stencils with electroformed apertures for micro-components, traceable materials, and rugged coatings to withstand extreme conditions (e.g., high altitude, radiation).

The industry is evolving to meet emerging electronics demands:

Digital Twin Integration: Virtual stencil prototypes are tested in digital twins of client production lines, reducing physical prototyping time by 40%.On-Demand Production: Quick-turn custom stencil services (24–48 hour lead times) support rapid prototyping for startups and agile development teams.Sustainable Customization: Recyclable stencil materials and water-based coatings are integrated into custom production, aligning with client ESG goals.

Custom SMT Stencils Manufacturing is a cornerstone of specialized electronics production, turning unique design challenges into assembly solutions. By prioritizing collaboration, aperture engineering, and process flexibility, manufacturers deliver stencils that optimize solder paste accuracy, reduce defects, and align with industry-specific constraints. As electronics designs grow more diverse and demanding, custom SMT stencils will remain essential—empowering businesses to bring innovative, specialized products to market efficiently and reliably.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB