-

- PCB TYPE

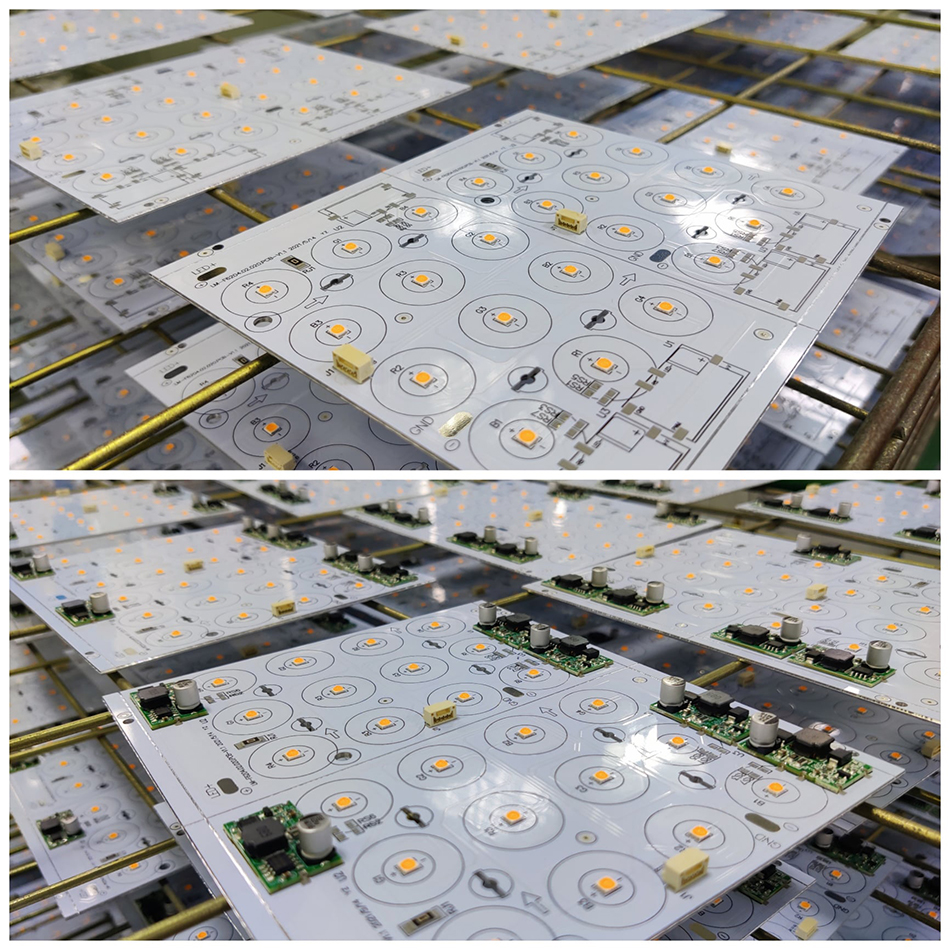

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 23. 2025, 17:53:02

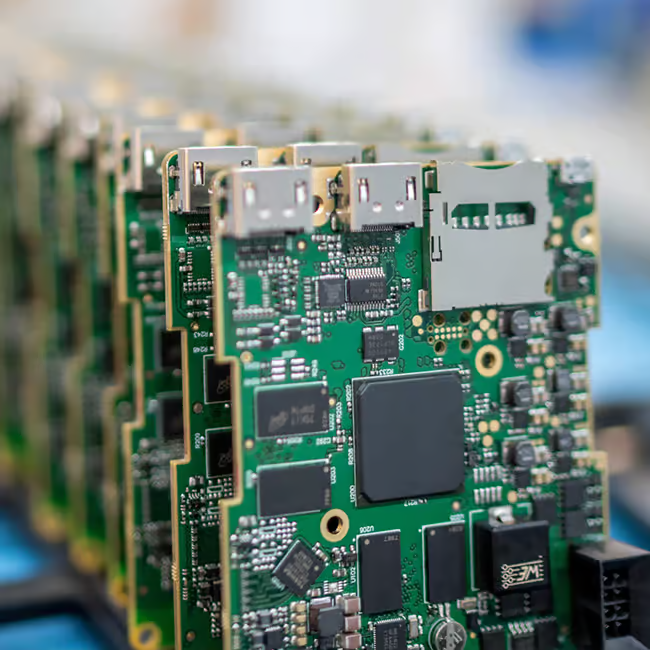

In the world of electronics, printed circuit boards (PCBs) serve as the backbone for all electronic devices. However, without a proper enclosure, these sophisticated boards remain vulnerable to damage and environmental factors. This is where custom PCB box building solutions come into play. Designing the right enclosure not only protects the PCB but also enhances the overall functionality and aesthetics of the device.

Custom PCB box building solutions refer to the tailored design and manufacturing of enclosures specifically for PCBs. These boxes can vary in size, shape, material, and features, depending on the specific requirements of the device they are meant to house.

The primary goal is to safeguard the PCB while ensuring that the enclosure meets the design and operational needs of the end product.

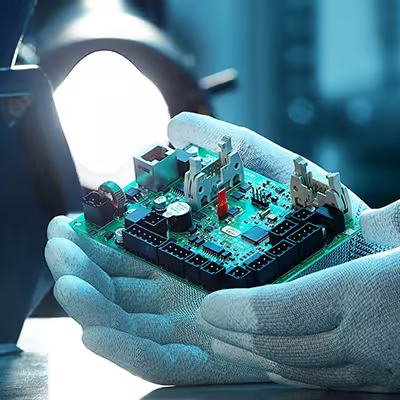

One of the main reasons to invest in a custom PCB box is to protect the delicate components on the board. A well-designed enclosure will shield the PCB from dust, moisture, and physical impacts. Moreover, it can help in maintaining the structural integrity of the board by providing a firm support system.

PCBs can generate a significant amount of heat during operation. Custom enclosures can be designed with features like ventilation slots or heat sinks to ensure proper heat dissipation, which is crucial for maintaining the performance and longevity of the electronic device.

For consumer-facing products, the exterior design of the device is just as important as the internal components. A custom PCB box allows for creative freedom in design, enabling companies to incorporate branding elements and achieve a sleek, professional appearance.

Certain industries require devices to meet specific safety and quality standards. Custom PCB boxes can be designed to comply with these standards, ensuring that the product is both safe and market-ready.

The process of designing a custom PCB box involves several key steps:

Before starting the design process, it is essential to identify the specific needs of the PCB and the device it will be used in. This includes understanding the size and shape of the PCB, the environmental conditions it will face, and any additional features required for the enclosure.

The choice of material is crucial in custom PCB box design. Common materials include plastics, metals, and composites, each offering different levels of protection, weight, and cost. The selection will depend on the specific requirements of the application, such as the need for electromagnetic interference (EMI) shielding or impact resistance.

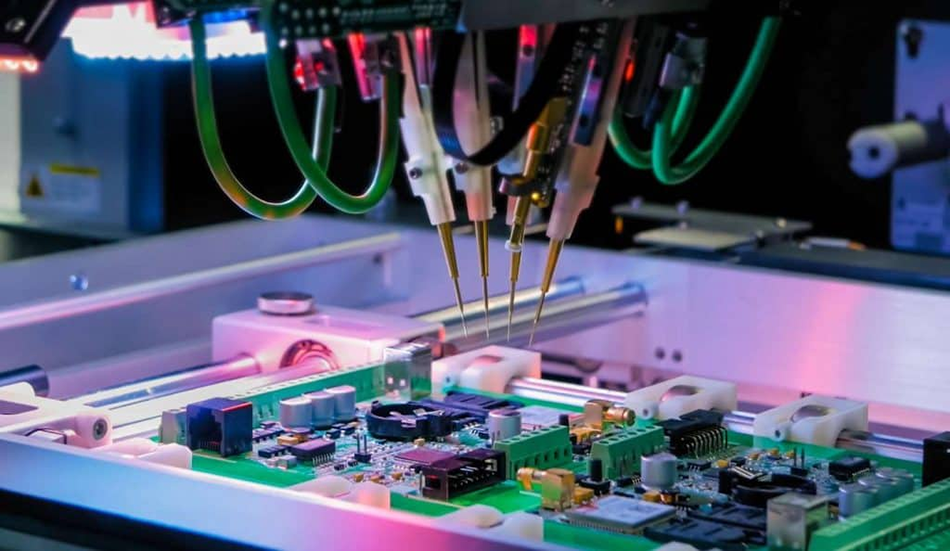

Once the design is finalized, a prototype of the PCB box is created. This prototype is used to test the fit, function, and performance of the enclosure. Any necessary adjustments are made during this phase to ensure the final product meets all design specifications.

After successful prototyping and testing, the PCB box moves into the manufacturing phase. This involves the production of the enclosure using the chosen materials and manufacturing processes. Depending on the complexity and volume, this can be done through methods like injection molding, die casting, or 3D printing.

Custom PCB boxes are designed to fit the specific dimensions and layout of a given PCB. This ensures a snug fit, preventing movement and reducing the risk of damage during use or transport.

With custom solutions, additional features can be integrated into the enclosure design. This can include mounting options, cable management systems, or user interface components like buttons and displays.

While custom solutions may have higher upfront costs, they can lead to savings in the long run. A well-designed enclosure reduces the risk of damage and extends the life of the device, minimizing repair and replacement costs.

A unique, high-quality enclosure can set a product apart from competitors. It not only adds to the aesthetic appeal but also enhances the perceived value of the product.

Custom PCB boxes are used across various industries, each with its own set of requirements and standards. Some common applications include:

In consumer electronics, aesthetics and branding are paramount. Custom enclosures allow for creative designs that align with brand identity while providing essential protection for the PCB.

For industrial applications, durability and compliance with safety standards are critical. Custom PCB boxes in this sector are often designed to withstand harsh environmental conditions and provide robust protection.

Medical devices require enclosures that meet stringent regulatory standards. Custom solutions ensure that these devices are both safe and reliable.

In automotive applications, custom PCB boxes must be able to withstand extreme temperatures and vibrations. They also need to integrate seamlessly into the vehicle’s design.

Custom PCB box building solutions offer significant advantages for any electronic device. From providing essential protection and enhancing functionality to boosting aesthetics and ensuring compliance, a well-designed enclosure is crucial for the success of a product.

Investing in custom solutions not only safeguards the delicate components of the PCB but also adds value to the overall device. Whether you're developing consumer electronics, industrial equipment, or any other electronic application, custom PCB boxes are an essential component of your design strategy.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB