-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 29. 2025, 16:13:06

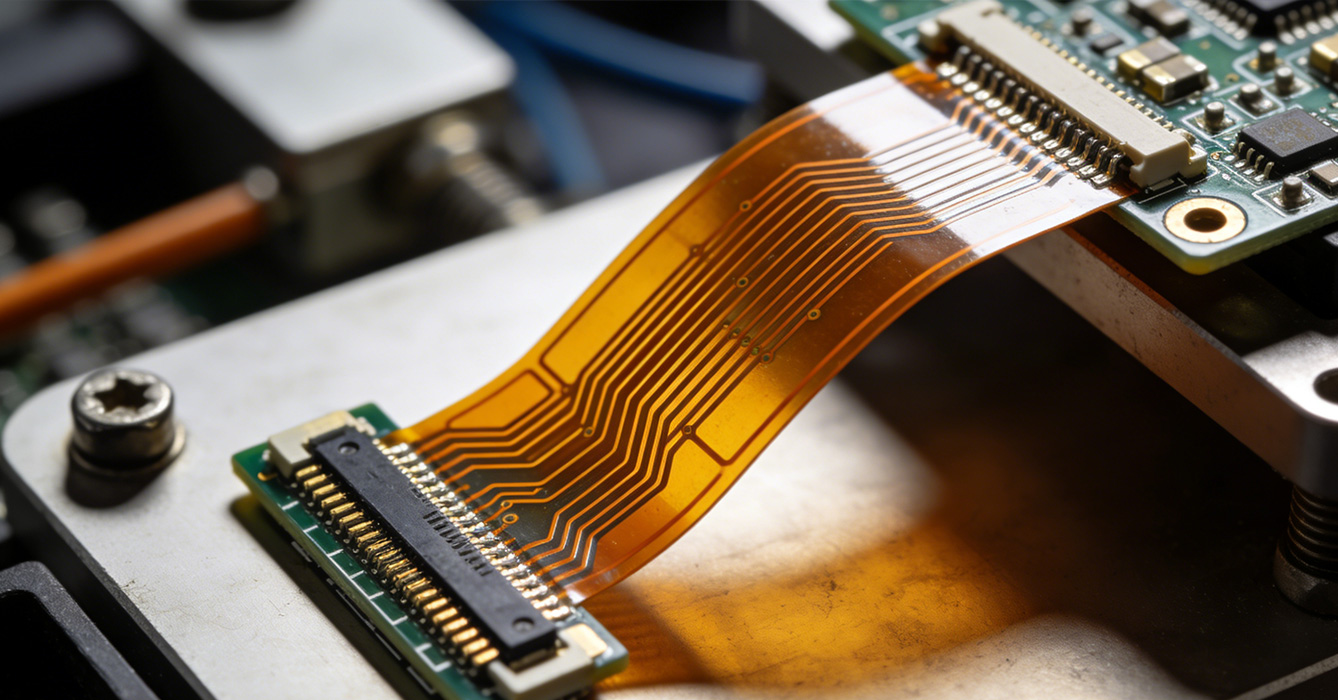

In the era of high-end electronics where miniaturization, high integration, and scenario-specific performance are paramount, the role of a Custom Precision FPCB Manufacturer has become increasingly pivotal. Unlike standard FPCB manufacturers that focus on mass-produced, off-the-shelf solutions, a Custom Precision FPCB Manufacturer specializes in delivering tailored flexible circuit boards that meet the unique precision requirements of complex electronic systems. From medical devices requiring ultra-miniature and biocompatible designs to aerospace electronics demanding extreme environmental resistance, these manufacturers bridge the gap between innovative product concepts and practical, high-precision manufacturing. Their ability to combine customized design flexibility with rigorous precision control makes them indispensable partners for industries pursuing technological breakthroughs.

A standout Custom Precision FPCB Manufacturer differentiates itself through two core capabilities that define its value in high-end electronics. Firstly, it possesses robust customized collaborative design capabilities. Recognizing that each high-end application has unique spatial constraints, performance requirements, and environmental conditions, these manufacturers engage in in-depth communication with clients at the early stages of product development. They provide professional design for manufacturability (DFM) advice, optimizing circuit layouts, material selection, and structural designs to ensure that the custom FPCB not only meets the functional needs but also is compatible with subsequent production processes.

Secondly, rigorous precision manufacturing and quality control systems are the cornerstone of their competitiveness. Custom precision FPCB production relies on advanced technologies such as laser direct imaging (LDI) and automated optical inspection (AOI) to achieve high-precision circuit patterning and defect detection. These manufacturers implement full-process quality monitoring, from the inspection of raw materials to the final electrical performance testing, ensuring that each custom FPCB maintains consistent precision and reliability. Additionally, they have the ability to adapt to diverse production scales, seamlessly transitioning from small-batch prototype customization to medium-volume production to meet the different stages of client product development.

The tailored precision solutions provided by Custom Precision FPCB Manufacturers have become a key enabler for innovation in multiple high-end industries. In the medical device sector, they play a crucial role in the development of minimally invasive surgical instruments and implantable monitoring devices. These applications require custom FPCBs that are ultra-miniature, biocompatible, and capable of stable signal transmission in the human body—requirements that only a professional Custom Precision FPCB Manufacturer can fulfill through tailored material selection and precision design.

In the aerospace and defense industry, Custom Precision FPCB Manufacturers supply high-reliability FPCBs for satellite communication systems and avionics equipment. These custom FPCBs must withstand extreme conditions such as extreme temperatures, strong vibrations, and radiation, requiring precise control of material properties and circuit integrity during the manufacturing process. The industrial robotics sector also benefits significantly, as custom precision FPCBs enable the miniaturization and flexibility of robot joints, supporting precise movement and sensor signal transmission in complex industrial environments.

Choosing the right Custom Precision FPCB Manufacturer is critical to the success of high-end electronic product development. Firstly, evaluate the manufacturer's customized design capabilities and industry experience. Prioritize manufacturers that have a proven track record in your specific industry, as they will better understand the unique requirements and regulatory standards of the sector. Reviewing their past case studies and client testimonials can help verify their ability to deliver tailored precision solutions.

Secondly, assess their precision manufacturing equipment and quality control system. A reliable manufacturer should be equipped with advanced production and testing equipment and hold relevant international certifications, ensuring that their production processes and product quality meet global high-end standards. Thirdly, consider their service response speed and collaboration capabilities. In the high-end electronics industry, product development cycles are often tight, so a manufacturer that can provide timely technical support and flexible customization services will help accelerate the product launch process. Finally, pay attention to their material supply chain stability, as high-quality raw materials are the foundation of precision FPCB production.

As high-end electronics continue to evolve toward intelligence and sustainability, Custom Precision FPCB Manufacturers are actively exploring new development directions. One key trend is the integration of artificial intelligence (AI) into the customization process. By leveraging AI algorithms to optimize circuit design and predict potential manufacturing issues, manufacturers can shorten the customization cycle and improve design accuracy.

Sustainability has also become an important development focus. Many Custom Precision FPCB Manufacturers are transitioning to eco-friendly materials and lead-free production processes, reducing the environmental impact of their products. Additionally, the development of advanced materials such as high-temperature-resistant and biodegradable substrates is expanding the application boundaries of custom precision FPCBs, enabling their use in more extreme and environmentally sensitive scenarios.

In conclusion, a Custom Precision FPCB Manufacturer is a strategic partner that empowers innovation in high-end electronics through tailored precision solutions. Their core competencies in customized collaborative design and rigorous precision manufacturing make them indispensable in industries such as medical devices, aerospace, and industrial robotics. By carefully evaluating a manufacturer's design capabilities, production equipment, service level, and supply chain stability, businesses can select a partner that aligns with their high-end product development goals. As the demand for smarter, more precise, and sustainable high-end electronics grows, the role of Custom Precision FPCB Manufacturers will become even more critical in shaping the future of the electronics industry.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB