-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 28. 2025, 11:02:55

The wearable technology sector is defined by its relentless pursuit of miniaturization, comfort, and uncompromised performance—attributes that place immense demands on the underlying electronic components. A specialized Customized FPC Manufacturer for Wearables emerges as a critical partner in this ecosystem, delivering flexible printed circuits (FPCs) tailored to the unique constraints of wearable devices. Unlike generic FPC suppliers, these manufacturers combine deep expertise in wearable design requirements with agile customization capabilities, creating circuits that conform to ergonomic shapes, withstand repeated bending, and integrate seamlessly with sensors, batteries, and other compact components. For wearable brands and innovators, partnering with a dedicated customized FPC manufacturer is not just a supply chain decision; it’s a strategic enabler of products that resonate with consumers and stand out in a competitive market.

Wearable devices—from smartwatches and fitness trackers to medical wearables and smart clothing—present unique challenges that off-the-shelf FPCs cannot address. These challenges drive the need for tailored solutions from a specialized manufacturer:

- Ergonomic Conformity: Wearables must fit snugly on the body, requiring FPCs that can bend, twist, and conform to curved or irregular shapes. Customized FPCs are designed to match the exact form factor of the device, ensuring comfort without sacrificing electrical performance.

- Space Optimization: Wearables pack dozens of components (heart rate sensors, GPS modules, small batteries) into tiny enclosures. A Customized FPC Manufacturer for Wearables creates dense, compact circuit layouts that maximize space efficiency, enabling thinner, lighter devices.

- Mechanical Durability: Unlike static electronics, wearables endure daily mechanical stress—from bending during movement to accidental impacts. Customized FPCs use specialized materials and reinforcement techniques to withstand thousands of flex cycles without trace damage or connection failure.

- Biocompatibility & Environmental Resistance: Wearables in direct contact with skin require FPC materials that are hypoallergenic and resistant to sweat, moisture, and body oils. Customized solutions prioritize biocompatible substrates and protective coatings to ensure user safety and long-term reliability.

To meet wearables’ unique demands, top customized FPC manufacturers offer a suite of specialized capabilities:

1. Collaborative Design Engineering: They work closely with wearable brands from the early concept stage, providing design for manufacturability (DFM) insights to optimize FPC layouts for form factor, flexibility, and component integration. This collaborative approach reduces design iterations and accelerates time-to-market.

2. Material Customization: They offer a range of specialized materials—including ultra-thin polyimides, flexible adhesives, and conductive inks—to match the specific needs of the wearable. For example, medical wearables may use biocompatible substrates, while outdoor fitness trackers require moisture-resistant materials.

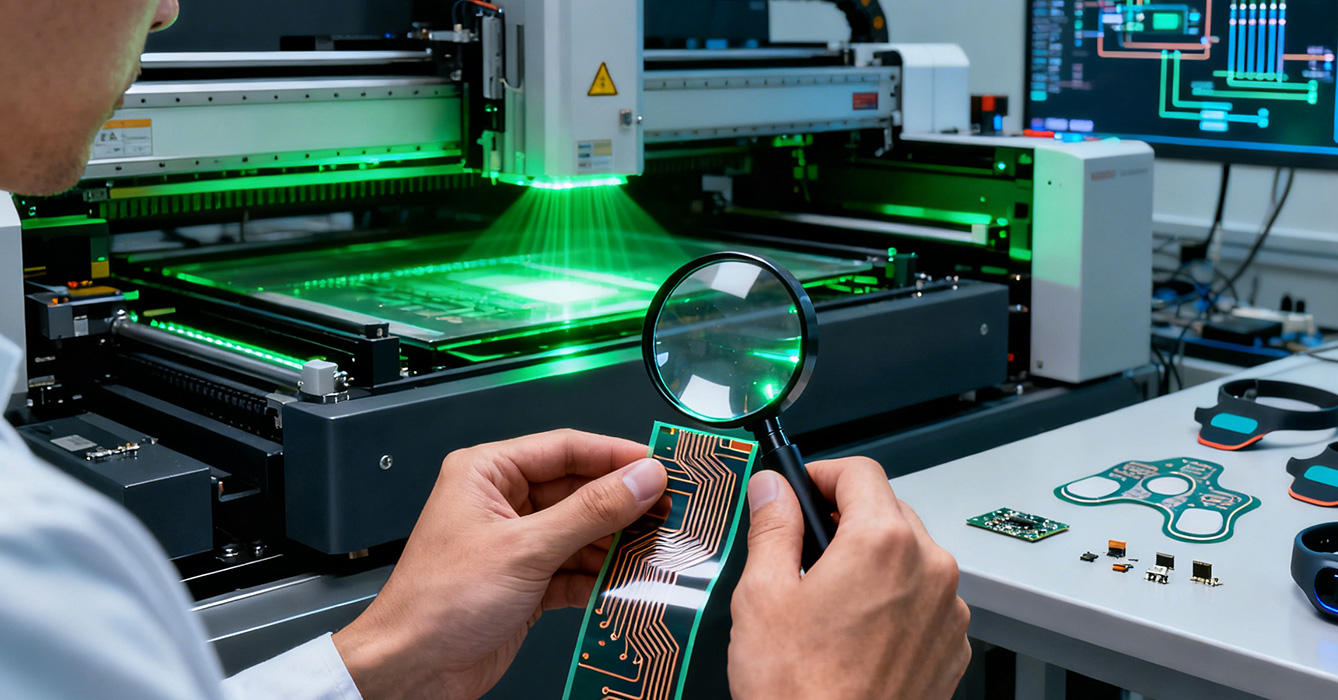

3. Precision Manufacturing for Miniaturization: Leveraging advanced lithography and etching technologies, they create ultra-fine circuit traces and micro-sized pads, enabling high-density layouts that fit within the tight constraints of wearable enclosures. This precision ensures signal integrity for sensitive sensors and wireless communication modules.

4. Customized Reinforcement & Protection: They add targeted reinforcement layers to high-stress areas (e.g., connector points, fold zones) and apply specialized coatings (such as hydrophobic or anti-microbial finishes) to enhance durability and user safety. These customizations are tailored to the device’s intended use case—whether it’s a waterproof fitness tracker or a skin-contact medical patch.

5. Rigorous Quality & Reliability Testing: They subject customized FPCs to wearable-specific testing, including flex cycle testing, sweat resistance testing, biocompatibility screening, and temperature cycling. This ensures the FPCs perform reliably in real-world wearable environments.

A Customized FPC Manufacturer for Wearables plays a pivotal role in advancing innovation across key wearable segments:

- Fitness & Consumer Wearables: Powers smartwatches, fitness bands, and smart clothing with FPCs that integrate heart rate sensors, accelerometers, and wireless charging modules. Customized layouts enable slim designs and long battery life, critical for consumer adoption.

- Medical Wearables: Enables life-saving devices like continuous glucose monitors, ECG patches, and sleep apnea trackers. Customized FPCs meet strict medical standards for biocompatibility and reliability, while their flexibility allows for comfortable, long-term skin contact.

- Industrial & Sports Performance Wearables: Supports rugged wearables for athletes (e.g., GPS-enabled sports watches) and industrial workers (e.g., safety monitoring devices). Customized FPCs withstand extreme temperatures, moisture, and mechanical stress, ensuring performance in harsh environments.

- Smart Fashion & Luxury Wearables: Blends FPCs seamlessly into clothing, jewelry, and accessories. Customized designs match the aesthetic of the product while maintaining flexibility and functionality—enabling innovations like LED-embedded dresses or smart bracelets.

For wearable brands, partnering with a Customized FPC Manufacturer for Wearables delivers distinct competitive benefits:

- Faster Time-to-Market: Collaborative design support and agile customization processes reduce design cycles, enabling brands to launch new products ahead of competitors.

- Superior Product Quality: Wearable-specific testing and material customization ensure FPCs are reliable, durable, and user-friendly—reducing warranty claims and enhancing brand reputation.

- Design Differentiation: Customized FPCs enable unique form factors and features (e.g., foldable displays, integrated sensors) that set products apart in a crowded market.

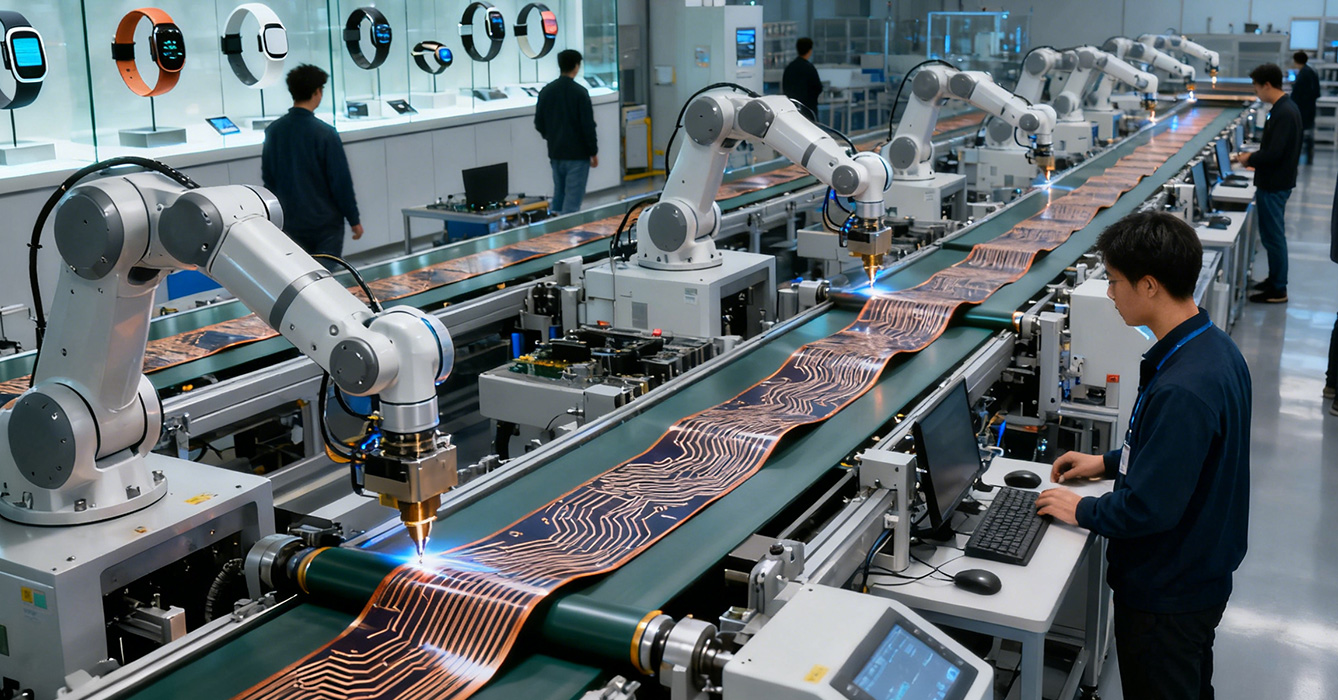

- Scalability: Leading manufacturers offer flexible production capabilities, supporting small-batch prototyping and large-scale mass production—adapting to the brand’s growth from concept to commercialization.

In conclusion, a Customized FPC Manufacturer for Wearables is an indispensable partner in the development of next-generation smart wearable devices. By combining deep expertise in wearable design constraints with agile customization capabilities, these manufacturers deliver FPCs that enable compact, comfortable, and reliable products. As the wearable market continues to evolve—with trends toward greater miniaturization, advanced sensing, and seamless connectivity—the role of specialized customized FPC manufacturers will only grow. For brands seeking to innovate and succeed in this dynamic sector, partnering with a manufacturer that understands the unique needs of wearables is the key to turning visionary concepts into market-leading products.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB