-

- PCB TYPE

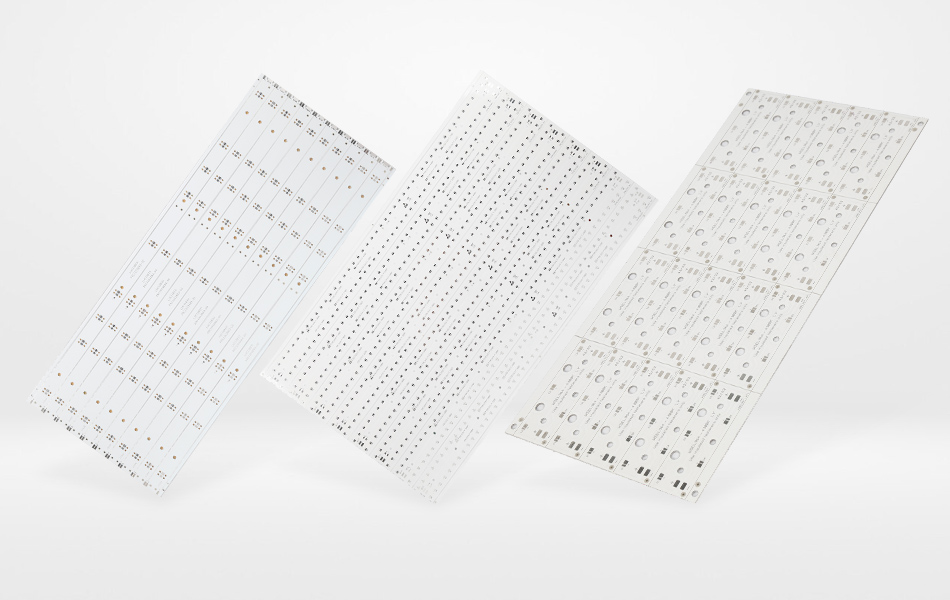

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 09. 2025, 15:26:31

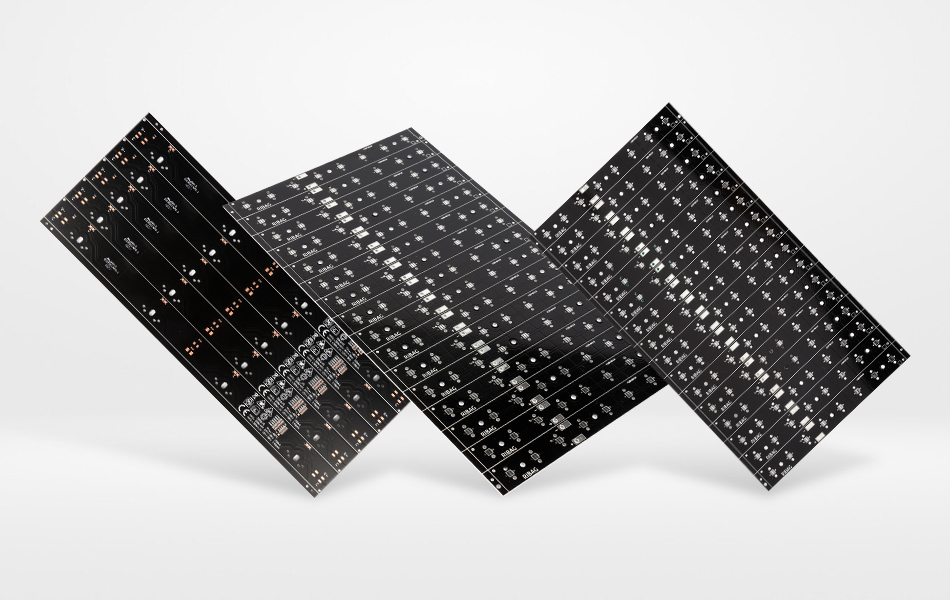

In the dynamic landscape of modern electronics, double sided aluminum printed circuit boards (PCBs) have emerged as a cornerstone technology, merging the thermal advantages of aluminum with the design versatility of dual-sided layouts. These PCBs are engineered to address the challenges of high-power density, compact form factors, and harsh operating environments, making them indispensable in industries ranging from aerospace to consumer electronics. This article explores the core principles, material strategies, design methodologies, and industrial applications of double sided aluminum PCBs, highlighting their role in enabling next-generation electronic systems.

Structural Fundamentals and Key Advantages

Layered Architecture for Balanced Performance

A double sided aluminum PCB features a three-layer construction designed to optimize thermal, electrical, and mechanical performance:

Central Aluminum Substrate: Serves as the foundational layer, providing robust mechanical support and acting as an efficient heat sink. Its high thermal conductivity ensures rapid dissipation of heat generated by components on both the top and bottom surfaces.

Dual Dielectric Layers: Thin insulating layers bond to the aluminum substrate, separating it from the top and bottom copper layers. These layers ensure electrical isolation while facilitating efficient heat transfer from components to the aluminum core.

Top and Bottom Copper Layers: Conductive pathways for signal transmission and power distribution, enabling dual-sided component mounting. This configuration allows for dense layouts, accommodating a mix of surface-mount (SMT) and through-hole components to maximize board space utilization.

Core Advantages for Modern Electronics

Space Efficiency: Dual-sided component placement reduces board area by up to 50% compared to single-sided designs, making it ideal for compact devices such as wearables, portable electronics, and high-density industrial controls.

Symmetrical Thermal Management: The aluminum substrate enables balanced heat dissipation from both sides, minimizing temperature gradients and preventing thermal hotspots. This is critical for high-power applications like dual-sided LED arrays or back-to-back power modules.

Design Flexibility: Supports complex circuit routing with separate signal and power layers on each side, reducing crosstalk and enabling high-frequency signal transmission in applications such as wireless communication and advanced sensor systems.

Material Selection for Optimal Performance

Aluminum Substrate Alloys

6xxx Series Alloys: Alloys such as 6061 and 6063 are preferred for their balanced properties. 6061 offers enhanced mechanical strength, making it suitable for rugged environments, while 6063 provides better formability for intricate shapes required in architectural lighting and consumer devices.

Substrate Thickness: Tailored to application requirements, with thinner substrates chosen for portable devices to minimize weight and space, and thicker substrates used in industrial settings to enhance heat capacity and mechanical rigidity.

Dielectric Layer Options

Polyimide Dielectrics: Renowned for their high-temperature resistance and low dielectric loss, these materials are essential for demanding environments such as aerospace avionics and automotive electronics, where reliability under extreme conditions is critical.

Ceramic-Filled Epoxies: Cost-effective and versatile, these materials offer moderate thermal conductivity and electrical insulation, making them suitable for mass-market applications like LED lighting, power supplies, and general-purpose electronics.

Copper Layers

Copper Foil: Selected based on current requirements, with thinner foils used for signal traces to minimize signal loss and thicker foils for power paths to reduce resistance and heat generation.

Design Methodologies for Thermal and Electrical Excellence

Thermal Management in Dual-Sided Layouts

Component Placement Strategies

Balanced Heat Distribution: High-power components such as power transistors, LEDs, and voltage regulators are strategically placed on both sides of the PCB to leverage the aluminum substrate's dual-sided heat dissipation capabilities. Thermal vias, which connect the copper layers to the aluminum core, are positioned beneath these components to create direct heat dissipation pathways, reducing thermal resistance and maintaining optimal operating temperatures.

Heat Sink Integration: External heat sinks can be attached to either or both sides of the PCB, with the aluminum substrate acting as a heat spreader to enhance convective cooling. This is particularly effective in high-power applications such as server power supplies and industrial inverters, where uniform temperature distribution is essential for component longevity.

Via Design for Efficient Heat Transfer

Through-Vias: Penetrate the entire board to connect both copper layers to the aluminum substrate, enabling maximum heat transfer in high-power zones. Their placement is optimized using thermal simulation tools to ensure even heat distribution and avoid localized hotspots.

Blind Vias and Via-in-Pad Technology: Used in dense layouts to localize heat dissipation without compromising trace routing. Via-in-pad technology allows direct heat extraction from component solder pads, improving thermal performance in space-constrained designs.

Electrical Design for Signal Integrity

Dual-Sided Trace Routing

Signal Separation: High-speed signals are routed on one side of the PCB, while power traces are placed on the opposite side, separated by the aluminum substrate to minimize electromagnetic interference (EMI). Differential pairs with controlled impedance are used for sensitive signals to ensure integrity in high-frequency applications such as HDMI, USB, and Ethernet interfaces.

Ground Plane Optimization: A solid ground plane on one or both copper layers provides a low-impedance return path, reducing EMI and improving noise immunity. Split ground planes are employed in mixed-signal designs to isolate analog and digital sections, preventing ground loop issues and enhancing signal clarity.

Power Distribution Strategies

Dual-Layer Power Planes: Copper planes on both sides of the PCB distribute high-current paths, reducing voltage drops and enabling parallel load sharing. Decoupling capacitors are placed on both layers near power pins to stabilize voltage supply and filter high-frequency noise, ensuring reliable operation of sensitive analog and digital circuits.

Mechanical and Environmental Design

Component Clearance and Assembly

3D Layout Engineering: Design tools ensure adequate clearance between components on both sides to prevent physical interference during assembly. Fiducial marks and alignment keys on both layers facilitate precise automated pick-and-place operations, ensuring accurate component placement in high-density layouts.

Mounting Solutions: Reinforced mounting holes with annular rings withstand mechanical stress in vibration-prone environments, such as automotive and industrial applications, ensuring the PCB remains securely fastened during operation.

Environmental Protection

Conformal Coatings: Protective coatings on both layers shield the PCB from moisture, dust, and chemical contaminants, making them suitable for outdoor lighting, marine electronics, and other harsh environments.

Thermal Cycling Resilience: The low coefficient of thermal expansion (CTE) of aluminum minimizes stress on solder joints during temperature fluctuations, ensuring reliable performance in applications exposed to extreme temperature variations, such as aerospace systems and automotive under-hood electronics.

Manufacturing Processes for Precision and Reliability

Substrate Preparation and Lamination

Precision Cutting: The aluminum substrate is cut to exact dimensions using CNC milling or laser cutting, followed by surface treatments to enhance the adhesion of dielectric layers and improve corrosion resistance.

Dual-Layer Lamination: High-pressure processes bond dielectric layers to both sides of the aluminum substrate, using prepregs or adhesive films to create void-free interfaces that are critical for efficient thermal and electrical performance. Automated presses control temperature and pressure to ensure uniform bonding across the entire substrate.

Copper Layer Fabrication

Double-Sided Foil Bonding: Electrolytic copper foil is laminated to both dielectric surfaces, followed by photolithography or laser direct imaging (LDI) for precise circuit pattern transfer. LDI is particularly useful for fine-pitch traces in high-density interconnect (HDI) designs, ensuring accurate feature sizes and spacing.

Chemical Etching: Automated systems remove unwanted copper, with post-etch inspection via automated optical inspection (AOI) to ensure trace integrity and eliminate defects such as bridging or trace thinning.

Via and Hole Formation

Drilling Technologies: Mechanical drilling is used for through-holes and large vias, while laser drilling enables the creation of microvias for dense layouts. Post-drilling processes include de-smearing and electroless copper plating to ensure conductive vias that connect both copper layers to the aluminum substrate, facilitating efficient heat and signal transfer.

Component Assembly

Double-Sided SMT: High-speed pick-and-place machines mount components on both sides, with reflow soldering profiles adjusted to account for the aluminum substrate's thermal mass. This ensures uniform heat application and consistent solder joint quality, even for fine-pitch components.

Through-Hole Processing: Selective soldering is used for through-hole components on one side, protecting components on the opposite side from heat damage during wave soldering and ensuring the integrity of pre-mounted components.

Quality Assurance for Robust Performance

Incoming Material Validation

Substrate Testing: Aluminum substrates are inspected for flatness, alloy composition, and thermal conductivity using non-destructive methods. Dielectric layers are tested for thickness, dielectric strength, and thermal impedance to ensure they meet design requirements.

Component Verification: Surface-mount and through-hole components are validated for specifications, ensuring compatibility with dual-sided layouts and soldering processes.

In-Process Quality Control

AOI and X-Ray Inspection: Automated optical systems check for trace defects, misaligned components, and solder joint issues on both sides. X-ray tomography is used to detect internal voids in lamination or plating inconsistencies that could affect thermal or electrical performance.

Thermal Profile Monitoring: During soldering, thermal cameras monitor temperature distribution on both layers to ensure uniform heat application and prevent thermal stress on components, particularly in high-power zones.

Final Performance Testing

Electrical Testing: Bed-of-nails fixtures test for continuity and isolation between layers, while network analyzers verify impedance matching for high-speed signals. High-voltage tests ensure dielectric integrity between copper layers and the aluminum substrate.

Thermal and Mechanical Testing: Infrared thermography maps temperature distribution under load, while thermal cycling and vibration tests evaluate the reliability of solder joints and mechanical durability, ensuring the PCB can withstand real-world operating conditions.

Industrial Applications of Double Sided Aluminum PCBs

High-Power LED Lighting

Commercial and Architectural Solutions: Dual-sided layouts enable compact, high-brightness LED panels with components on both sides, dissipating heat efficiently in ceiling lights, retail displays, and outdoor signage. The aluminum substrate ensures uniform light output and extends LED lifespan by maintaining optimal operating temperatures.

Automotive Lighting Systems: In headlamps and taillights, double sided PCBs reduce board size by mounting LEDs and drivers on both sides, with the aluminum substrate managing heat in tight, temperature-sensitive enclosures, enhancing safety and reliability.

Power Electronics and Energy Systems

Renewable Energy Inverters: Dual-sided mounting of IGBTs and diodes allows symmetrical heat dissipation, critical for efficient power conversion in solar and wind energy systems. The robust design withstands the high vibrations and temperature fluctuations of generator environments.

Electric Vehicle (EV) Chargers: Dense power modules on both sides of the PCB, combined with the aluminum substrate’s heat-spreading capabilities, ensure reliable operation in compact EV charging stations, even under continuous high-current loads.

Automotive Electronics

Advanced Driver-Assistance Systems (ADAS): Dual-sided placement of image sensors, processors, and radar modules reduces package size, with thermal vias preventing overheating in camera modules exposed to direct sunlight. The rugged design withstands the harsh vibrations and temperature extremes of vehicle operation.

Engine Control Units (ECUs): Conformal-coated double sided PCBs with reinforced mounting holes operate reliably in engine bays, where they are exposed to oil, moisture, and vibration, ensuring precise control of engine parameters.

Consumer Electronics and Wearables

Gaming Consoles and Laptops: Double-sided layouts of high-performance CPUs and GPUs manage heat in compact enclosures, enabling sustained performance during intensive use. The thin profile supports sleek, lightweight designs demanded by consumers.

Wearable Devices: Smartwatches and fitness trackers utilize double sided aluminum PCBs to accommodate sensors, batteries, and wireless modules on both sides, balancing thermal efficiency with minimal thickness for comfortable wear and extended battery life.

Industrial Control and Automation

Motor Drives and Robotics: Dual-sided mounting of IGBTs, FPGAs, and sensors ensures reliable operation in high-vibration industrial environments. Thermal vias enhance heat dissipation from both sides, critical for continuous operation in manufacturing machinery and automated systems.

Process Control Systems: Compact double sided PCBs with conformal coatings resist dust and moisture in industrial plants, supporting dense layouts of control circuitry and communication modules for real-time process monitoring and control.

Emerging Trends in Double Sided Aluminum PCB Design

Miniaturization and High-Density Integration

Microvia Technology: Laser-drilled microvias and fine-pitch traces enable high-density interconnects in IoT sensors, 5G modules, and wearable devices, where space is severely constrained but performance demands are high.

3D Component Stacking: Double sided PCBs facilitate vertical integration of components and modules, creating compact 3D systems with enhanced thermal and electrical performance, ideal for advanced mobile devices and embedded systems.

Advanced Thermal Solutions

Hybrid Substrates: Composite materials combining aluminum with high-thermal-conductivity layers such as graphite or carbon fiber enhance heat dissipation, enabling higher power densities in applications like 5G power amplifiers and high-performance computing modules.

Active Cooling Integration: Micro-channel structures etched into the aluminum substrate allow for direct liquid cooling, used in extreme-power applications to achieve ultra-efficient heat removal and support next-generation electronic systems.

Sustainable Manufacturing Practices

Eco-Friendly Materials: The use of recycled aluminum and water-based dielectric adhesives reduces the environmental footprint, aligning with global sustainability goals. Lead-free surface finishes and energy-efficient manufacturing processes further enhance the ecological profile of double sided aluminum PCBs.

Waste Reduction: Automated manufacturing lines with precise material cutting and minimal scrap generation contribute to a more sustainable production process, minimizing waste and resource consumption.

Automation and Digital Design Tools

AI-Powered Layout Optimization: Machine learning algorithms analyze thermal and electrical data to optimize component placement and via routing, reducing design time and eliminating thermal hotspots in complex dual-sided layouts.

Robotic Assembly Solutions: High-precision robotic arms with real-time vision systems ensure accurate placement of delicate components on both sides, improving yield in high-volume production and enabling micro-pitch applications.

Conclusion

Double sided aluminum PCBs represent a transformative solution in electronic engineering, offering a unique blend of thermal efficiency, design flexibility, and mechanical robustness. Their ability to support high-power density, dense component layouts, and harsh environments makes them essential in a wide range of industries, from consumer electronics to critical industrial and aerospace applications. As technology continues to drive towards miniaturization, sustainability, and extreme performance, double sided aluminum PCBs will evolve through material innovation, automation, and advanced thermal solutions. For engineers, mastering their design principles is key to creating reliable, efficient, and future-ready electronic systems that meet the challenges of a rapidly evolving technological landscape. By leveraging the strengths of dual-sided design and aluminum’s inherent properties, these PCBs are poised to play a central role in enabling the next generation of high-performance electronics.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB