-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 09. 2025, 15:17:28

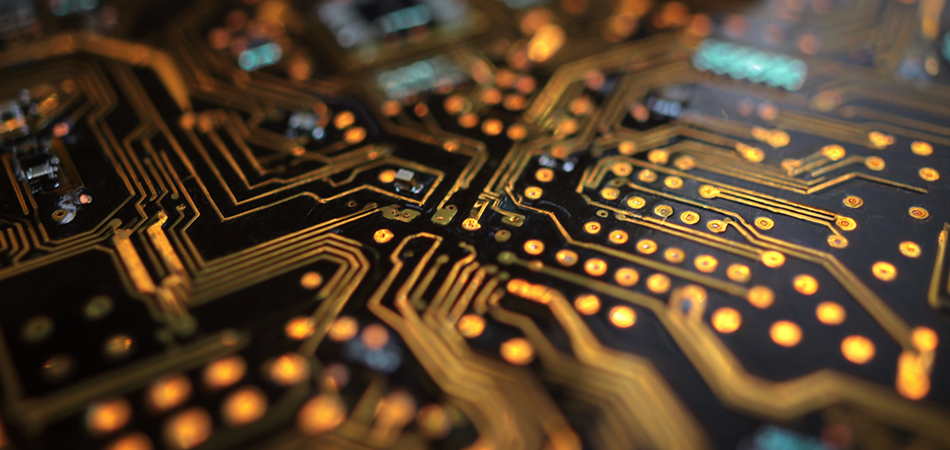

In the realm of high-precision electronic engineering, double sided aluminum printed circuit boards (PCBs) with Electroless Nickel Immersion Gold (ENIG) finish represent a pinnacle of reliability and performance. This combination of robust thermal management, dual-sided design flexibility, and superior surface finish is ideal for applications demanding long-term durability, fine-pitch component integration, and consistent electrical performance. This article explores the technical nuances of ENIG finish double sided aluminum PCBs, covering material selection, design principles, manufacturing processes, quality assurance, and industrial applications, while highlighting their role in enabling next-generation electronic systems.

Foundation of ENIG Finish Double Sided Aluminum PCBs

Structural Architecture

A double sided aluminum PCB with ENIG finish features a three-layer core structure enhanced by a premium surface treatment:

Central Aluminum Substrate: Provides mechanical stability and high thermal conductivity, serving as an efficient heat sink for components on both sides.

Dual Dielectric Layers: Insulate the aluminum substrate from top and bottom copper layers, balancing electrical isolation with thermal transfer efficiency.

ENIG-Coated Copper Layers: Both sides of the copper traces are protected by an ENIG finish, consisting of a thin nickel layer (5-7μm) and a micron-thick gold layer, creating a smooth, corrosion-resistant surface for component attachment.

Key Advantages for Critical Applications

Enhanced Solderability: The ENIG finish offers a uniform, oxidation-resistant surface, ensuring reliable solder joints for fine-pitch components like BGA (Ball Grid Array) and QFP (Quad Flat Package), which are common in high-density layouts.

Long-Term Reliability: The nickel barrier layer prevents copper diffusion, making ENIG - coated PCBs suitable for harsh environments where moisture, temperature fluctuations, or chemical exposure could degrade other surface finishes.

Signal Integrity: The flat gold surface minimizes contact resistance and signal loss in high-frequency applications, critical for maintaining data integrity in wireless communication and high-speed digital circuits.

Material Selection for Performance Optimization

Aluminum Substrate Alloys

6xxx Series Alloys (6061-T6, 6063): Chosen for their balance of thermal conductivity (180-210 W/mK) and mechanical strength. 6061-T6 is preferred for rugged environments, while 6063 allows for intricate shapes in compact devices.

Substrate Thickness: Tailored to application needs: thinner substrates (0.8-1.6mm) for portable electronics, thicker substrates (2.0-3.0mm) for industrial power modules requiring enhanced heat capacity.

Dielectric Layer Strategies

Polyimide Dielectrics: High-temperature resistance (up to 250°C) and low dielectric loss make them ideal for ENIG - coated boards in aerospace and automotive applications, where both thermal stability and signal integrity are critical.

Ceramic-Filled Epoxies: Cost-effective option with moderate thermal conductivity, suitable for commercial applications like high-reliability LED drivers and medical devices, combining ENIG's solderability with aluminum's thermal benefits.

ENIG Finish Composition

Electroless Nickel Layer: Provides a uniform, pore-free barrier against copper oxidation and serves as a foundation for the gold layer. Its thickness is optimized to balance corrosion resistance and flexibility.

Immersion Gold Layer: A thin (0.05-0.15μm) gold layer protects the nickel from oxidation, enhances solderability, and provides an inert surface for wire bonding in hybrid microcircuits.

Design Methodologies for ENIG-Coated Double Sided PCBs

Thermal Management in Dual-Sided Layouts

Symmetrical Heat Dissipation

Component Placement: High-power components (e.g., power amplifiers, voltage regulators) are distributed across both sides to leverage the aluminum substrate's dual-sided heat dissipation. Thermal vias connect both copper layers to the aluminum core, creating efficient pathways for heat to escape to external heat sinks or the ambient environment.

ENIG and Thermal Vias: The ENIG finish does not compromise thermal via efficiency; vias are plated through both copper layers, with the aluminum substrate ensuring uniform heat spreading, even under dense component layouts.

Thermal Via Design

Through-Vias for Full-Layer Connectivity: Essential for high-power zones, these vias penetrate the entire board, allowing heat to transfer from both sides to the aluminum substrate. Their placement is optimized using thermal simulation tools to avoid thermal hotspots.

Via-in-Pad Technique: Enables direct heat extraction from component pads on both sides, critical for devices like high-power LEDs where localized heat management is essential to prevent performance degradation.

Electrical Design for Signal and Power

Fine-Pitch Trace Routing

ENIG's Role in High-Density Layouts: The smooth gold surface facilitates precise soldering of fine-pitch components (down to 0.3mm pitch), enabling dense dual-sided layouts in applications like medical imaging devices and aerospace avionics.

Differential Pair Routing: High-speed signals (e.g., USB 3.1, HDMI 2.0) are routed on both sides with controlled impedance, supported by the ENIG finish's low contact resistance and the aluminum substrate's grounding plane to minimize EMI.

Power Distribution Strategies

Dual-Layer Power Planes: Copper planes on both sides, coated with ENIG, distribute high-current paths with minimal resistance. Decoupling capacitors are placed on both layers near power pins, leveraging the ENIG surface's excellent solderability for stable voltage regulation.

Ground Plane Design: A solid ground plane on one or both sides provides a low-impedance return path, enhanced by the ENIG finish's uniformity, which reduces noise coupling in mixed-signal circuits.

Mechanical and Environmental Design

Component Clearance and Alignment

3D Design Considerations: Design tools ensure adequate spacing between dual-sided components to avoid physical interference, with fiducial marks on both sides for precise automated assembly. ENIG's reflective surface aids in visual inspection of component placement.

Mounting Solutions: Reinforced mounting holes with ENIG-coated annular rings resist corrosion and mechanical stress, critical for applications exposed to vibrations, such as automotive ECUs and industrial robotics.

Environmental Protection

Conformal Coating Compatibility: ENIG finishes work seamlessly with acrylic or silicone conformal coatings, providing an additional layer of protection against moisture and chemicals. This is vital for outdoor LED displays and marine electronics.

Thermal Cycling Resilience: The combination of aluminum's low CTE and ENIG's resistance to thermal fatigue ensures stable solder joints during repeated temperature cycles, making these PCBs suitable for aerospace systems and high-reliability industrial controls.

Manufacturing Processes for ENIG Double Sided PCBs

Substrate Preparation and Lamination

Aluminum Substrate Processing: Precision cutting via CNC milling or laser cutting, followed by surface degreasing and micro-etching to enhance dielectric adhesion. The substrate's flatness is critical for uniform lamination of dual dielectric layers.

Dual-Layer Lamination: High-pressure processes bond polyimide or ceramic-filled epoxy dielectrics to both sides of the aluminum substrate, ensuring void-free interfaces that maintain thermal and electrical performance.

Copper Layer Fabrication

Double-Sided Foil Bonding: Electrolytic copper foil (1-2 oz for signals, 3-4 oz for power) is laminated to the dielectric layers, followed by photolithography to transfer circuit patterns. Laser direct imaging (LDI) is used for fine features (≤50μm traces) in high-density designs.

Chemical Etching: Automated systems remove unwanted copper, with post-etch inspection via AOI to ensure trace integrity. ENIG-compatible etch resist materials protect the copper during processing.

ENIG Finish Application

Electroless Nickel Plating

Pre-Treatment: Copper surfaces are activated with acid cleaning to remove oxides, followed by palladium catalyzation to initiate nickel deposition.

Nickel Deposition: A chemical bath deposits a uniform nickel layer (5-7μm), providing corrosion resistance and a base for gold adhesion.

Immersion Gold Plating

Gold Bath: The nickel-coated board is immersed in a gold solution, where a displacement reaction deposits a thin gold layer (0.05-0.15μm). This step is critical for achieving a solderable, oxidation-resistant surface.

Component Assembly

Double-Sided SMT: High-precision pick-and-place machines mount components on both ENIG-coated sides, with reflow soldering profiles adjusted to account for the aluminum substrate's thermal mass. The ENIG surface ensures consistent wetting of solder paste, reducing joint defects.

Through-Hole Processing: Selective soldering is used for through-hole components on one side, with the ENIG finish on the opposite side protected from thermal damage, ensuring integrity of pre-mounted components.

Quality Assurance for ENIG-Coated Double Sided PCBs

Material and Process Inspection

ENIG Thickness Testing: X-ray fluorescence (XRF) measures nickel and gold layer thickness to ensure compliance with design specifications, critical for long-term corrosion resistance.

Aluminum Substrate Validation: Non-destructive testing for flatness, alloy composition, and thermal conductivity ensures the substrate meets thermal management requirements.

In-Process Quality Control

AOI for ENIG Surfaces: Automated optical inspection checks for ENIG coating defects, such as pinholes or uneven deposition, which could compromise solderability or corrosion resistance.

X-Ray Tomography: Verifies via plating integrity and lamination quality, ensuring no voids or delaminations that could affect thermal or electrical performance.

Final Performance Testing

Electrical Testing

Solder Joint Shear Test: Measures the mechanical strength of component joints on ENIG surfaces, ensuring reliability for fine-pitch components.

High-Frequency Signal Testing: Network analyzers verify impedance matching and signal loss on ENIG-coated traces, critical for high-speed digital and RF applications.

Thermal and Environmental Testing

Infrared Thermography: Maps temperature distribution on both sides under load, ensuring balanced heat dissipation through the aluminum substrate and ENIG-coated layers.

Salt Spray and Humidity Tests: Evaluate ENIG's corrosion resistance and the PCB's overall durability in harsh environments, with exposure periods simulating years of operational stress.

Industrial Applications of ENIG Finish Double Sided Aluminum PCBs

Aerospace and Defense Electronics

Avionics Systems: Used in navigation modules and communication systems, where ENIG's corrosion resistance and double-sided density are essential for space-constrained, high-reliability environments. Thermal vias ensure stable operation at extreme temperatures.

Military Radars: Dual-sided layouts with ENIG finish support high-frequency signal routing and dense component placement, critical for maintaining signal integrity in rugged, mobile radar systems.

Medical Devices

Implantable Electronics: ENIG-coated double sided PCBs enable miniaturized, biocompatible designs for pacemakers and neural stimulators. The finish's inert surface and the aluminum substrate's thermal efficiency protect against body fluid corrosion and heat buildup.

Diagnostic Equipment: High-density layouts with fine-pitch connectors rely on ENIG's precise solderability for reliable data transmission in MRI and CT scanners, where signal clarity is non-negotiable.

High-End Consumer Electronics

Wearable Technology: Smartwatches and hearables use ENIG double sided PCBs to integrate sensors, batteries, and wireless modules on both sides, balancing compactness with thermal management for extended battery life.

Gaming Consoles: Dual-sided placement of high-performance CPUs and GPUs, combined with ENIG's low contact resistance, ensures stable power delivery and heat dissipation in compact, high-performance gaming systems.

Industrial Automation

Robotic Controllers: ENIG finish protects against dust and moisture in factory environments, while double-sided layouts minimize board size for robotic arm modules, where space and reliability are critical.

High-Precision Measurement Devices: ENIG's signal integrity and aluminum's thermal stability make these PCBs ideal for sensors and control systems in metrology equipment, ensuring accurate measurements over long periods.

Telecommunications

5G Small Cells: Dual-sided ENIG PCBs support dense RF component integration and high-speed data processing, with the aluminum substrate dissipating heat from power amplifiers in compact cell tower installations.

Optical Networking Equipment: ENIG-coated traces ensure low-loss signal transmission in fiber optic modems, while double-sided layouts reduce the size of rack-mounted networking devices.

Emerging Trends in ENIG Double Sided Aluminum PCB Design

Miniaturization with High-Density Interconnect (HDI)

Microvia and Fine-Pitch ENIG: Laser-drilled microvias (≤0.2mm) on ENIG-coated layers enable high-density interconnects in IoT sensors and wearable devices, where every millimeter of board space matters.

3D Packaging Integration: Double-sided ENIG PCBs facilitate stacking of components and modules, creating compact 3D systems with enhanced thermal and electrical performance, ideal for advanced mobile devices and embedded systems.

Sustainable ENIG Processes

Eco-Friendly ENIG Chemistry: Development of lead-free, low-ammonia ENIG baths reduces environmental impact, aligning with global sustainability standards like RoHS and REACH.

Recycled Aluminum Substrates: Integration of post-consumer recycled aluminum with ENIG finish creates a closed-loop solution, reducing the carbon footprint of high-reliability PCBs.

Advanced Thermal Solutions with ENIG

Hybrid Thermal Interfaces: ENIG-coated copper layers paired with graphite or carbon fiber sheets on the aluminum substrate enhance thermal conductivity, enabling higher power densities in 5G and AI accelerator modules.

Phase-Change Materials (PCM) Integration: PCMs bonded to ENIG surfaces on both sides of the PCB provide passive thermal regulation, absorbing and releasing heat to maintain component temperatures within tight ranges.

Automation and AI-Driven Design

AI-Optimized ENIG Layouts: Machine learning algorithms analyze ENIG's solderability and thermal properties to optimize component placement and via routing, reducing design iterations and improving yield in high-complexity boards.

Robotic ENIG Inspection: Automated robots with high-resolution vision systems verify ENIG coating uniformity and component alignment on both sides, ensuring zero-defect production in high-reliability applications.

Conclusion

ENIG finish double sided aluminum PCBs represent a fusion of premium surface treatment and robust thermal design, setting a new standard for high-reliability electronics. Their ability to support fine-pitch components, withstand harsh environments, and enable dense dual-sided layouts makes them indispensable in industries where performance and durability are non-negotiable. As technology progresses toward miniaturization, sustainability, and extreme precision, these PCBs will continue to evolve, driven by advancements in material science, automation, and thermal management. For engineers, leveraging the combined advantages of ENIG and double-sided aluminum design is key to creating innovative, future-ready systems that meet the escalating demands of modern electronics.

==========

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB