-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 25. 2025, 10:46:29

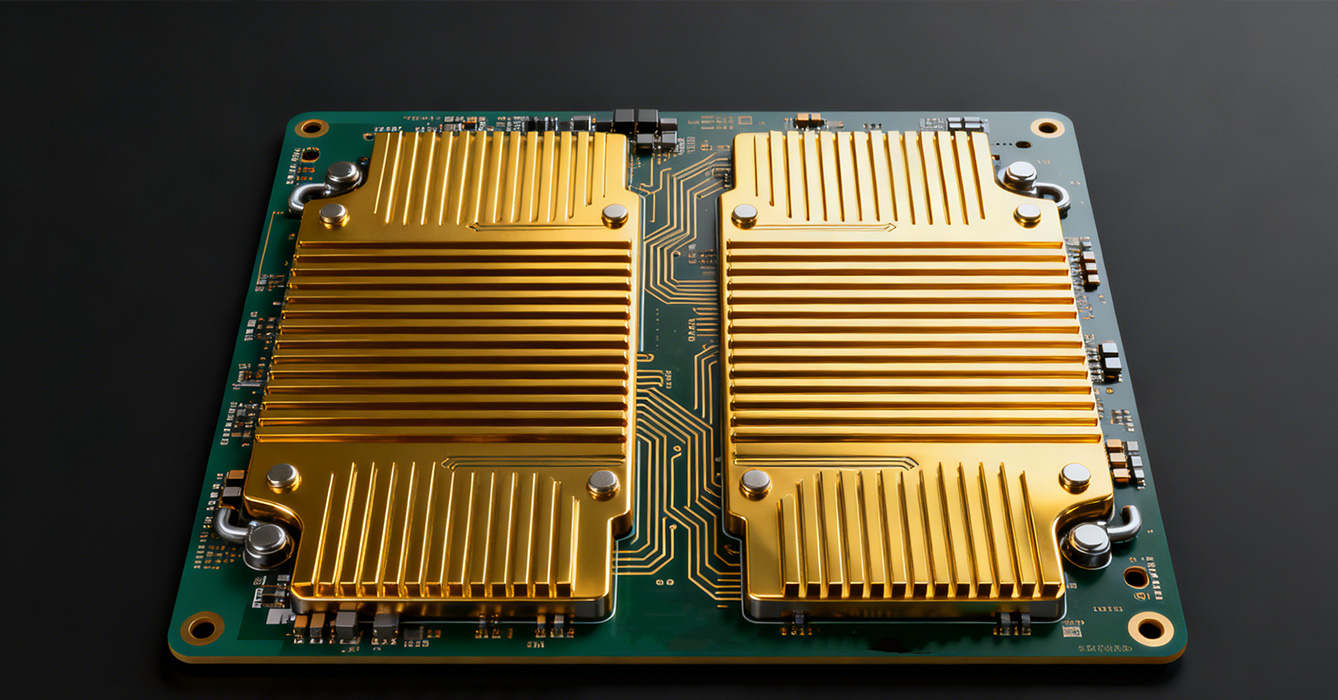

ENIG Finish Double Sided SinkPAD refers to a double-sided SinkPAD PCB that uses ENIG (Electroless Nickel Immersion Gold) as its surface finish. It combines the dual advantages of a double-sided SinkPAD’s integrated thermal management and ENIG’s stable surface performance, making it a preferred choice for high-power, high-precision electronic devices. Below is a detailed breakdown of its core features, key strengths, and typical applications:

This product integrates two core technologies, with their functions complementing each other to ensure both thermal management and electrical reliability:

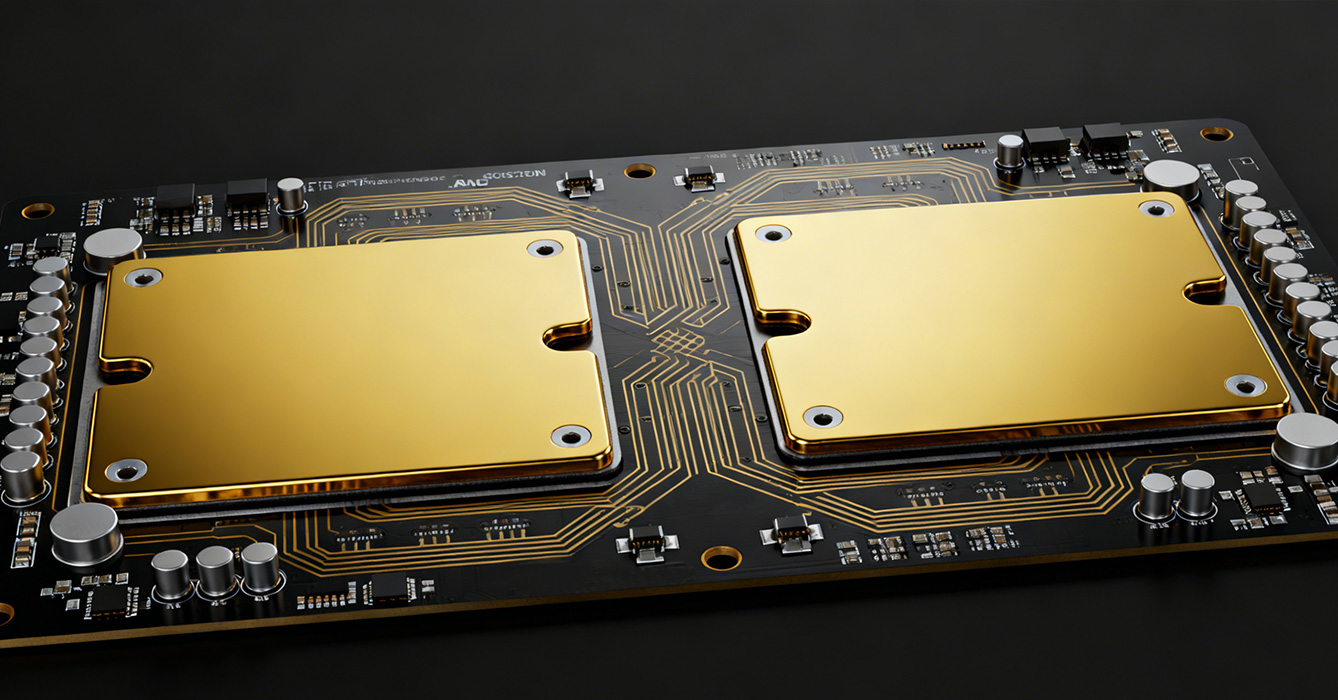

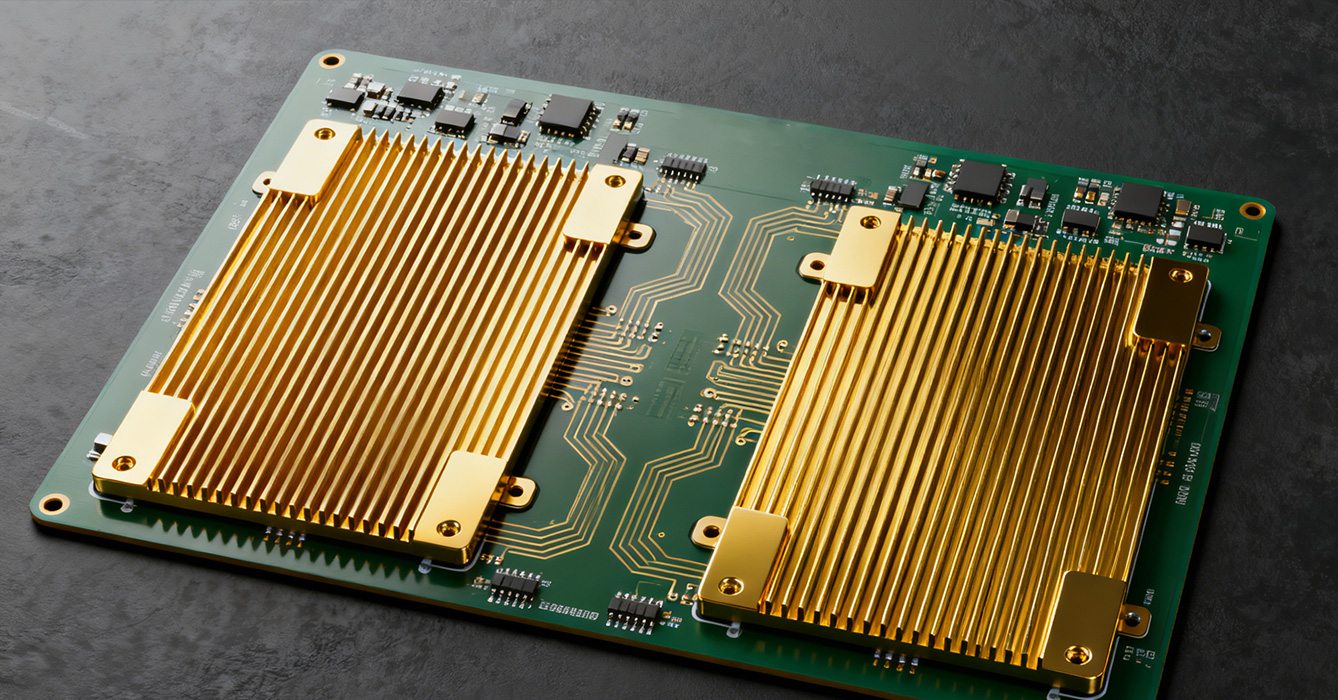

Double Sided SinkPAD Foundation: Unlike single-sided SinkPAD PCBs, it has built-in thermal sink structures on both the top and bottom layers. These sinks are usually copper cores, forming a thermoelectric separation structure. Components can be mounted on both sides, allowing for more complex circuit designs while quickly transferring heat from high-power components directly to the sink structure. This avoids local overheating and extends component lifespan. Notably, it has no plated through-holes (PTH) due to manufacturing process limitations, which needs to be considered in heat sink layout during design.

ENIG Surface Finish Enhancement: The ENIG finish consists of a nickel underlayer and a thin gold overlay. The nickel layer acts as a barrier to prevent copper oxidation and ensures good solderability, while the gold layer protects the nickel from corrosion and enables reliable electrical connections. This finish meets standards like IPC 4552, with controlled thicknesses for both layers to maintain consistency across the board surface.

Superior Assembly Adaptability for Fine-Pitch Components: The ENIG finish creates a flat, uniform surface, which is critical for soldering fine-pitch components such as small LEDs or integrated circuits with pitches as small as 0.4 - 0.5 mm. Unlike uneven finishes like HASL, it avoids connection instability or misalignment issues, ensuring smooth assembly of dense components on both sides of the SinkPAD.

Dual-Sided High-Power Bearing Capacity: With thermal sinks on both sides, it can mount high-power components (such as Cree XPL/XML LEDs, OSRAM LEDs, and power semiconductors) on either side, supporting power outputs up to 200W. The thermoelectric separation structure minimizes lumen depreciation in LEDs and reduces performance degradation in semiconductors.

Long-Term Reliability & Durability: ENIG finish resists corrosion and oxidation, giving the PCB an extended shelf life. It also withstands multiple thermal cycles, which is essential for devices operating under fluctuating temperatures. Meanwhile, the integrated sink structure enhances the PCB’s mechanical rigidity, resisting warpage and vibration during long-term use.

Compatibility with Multiple Connection Needs: The gold layer in ENIG enables reliable aluminum wire bonding in addition to conventional soldering. This expands its applicability in scenarios requiring both soldered components and wire-bonded connections, such as some high-power LED modules and semiconductor control circuits.

High-Power LED Lighting: It is ideal for products like LED high-bay lights, floodlights, and high-power LED strips. It supports both single high-power LEDs (e.g., Cree XHP series) and COB packaged LEDs, with its double-sided design and thermal management capability ensuring stable lumen output and prolonged service life even for 200W-class lighting fixtures.

Power Electronics: Suitable for high-power semiconductors including transistors, thyristors, and diodes. It can be used in industrial motor drives and power resistors, where its dual-sided heat dissipation and reliable soldering performance maintain stable operation of high-current components.

Specialized Electronic Equipment: It is applied in precision electronic devices that require long-term reliability, such as automotive auxiliary electronics and small industrial sensors. The ENIG finish complies with lead-free regulations, and the double-sided SinkPAD design fits the compact layout needs of these devices while addressing heat issues from high-power components.

In summary, ENIG Finish Double Sided SinkPAD bridges the gap between double-sided high-power thermal management and high-precision assembly, making it a high-performance solution for scenarios where both power density and reliability are critical. Its common base material is copper with thicknesses ranging from 0.8mm to 1.5mm, and it can be customized to panel sizes up to 600*500mm for mass production.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB