-

- PCB TYPE

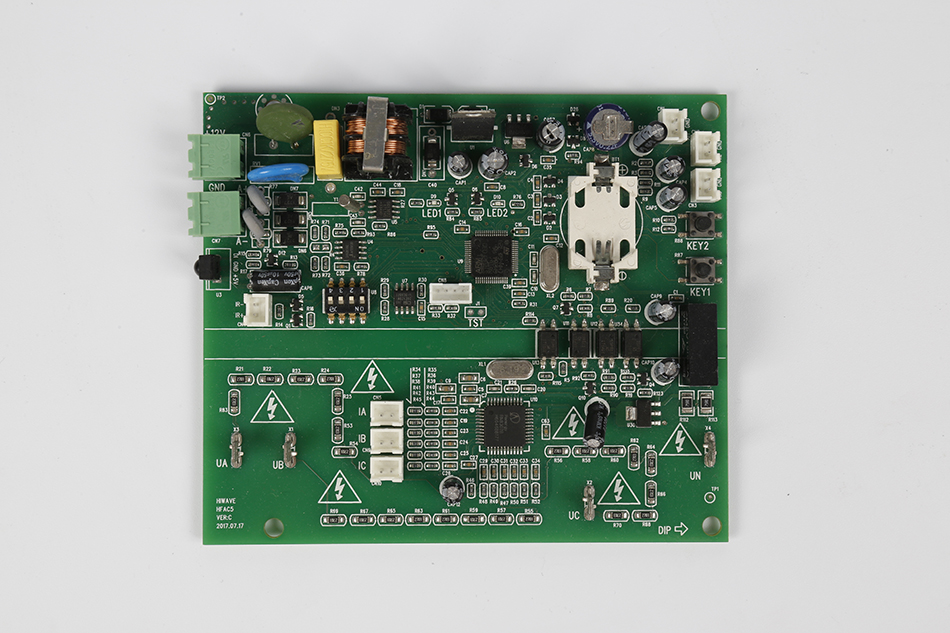

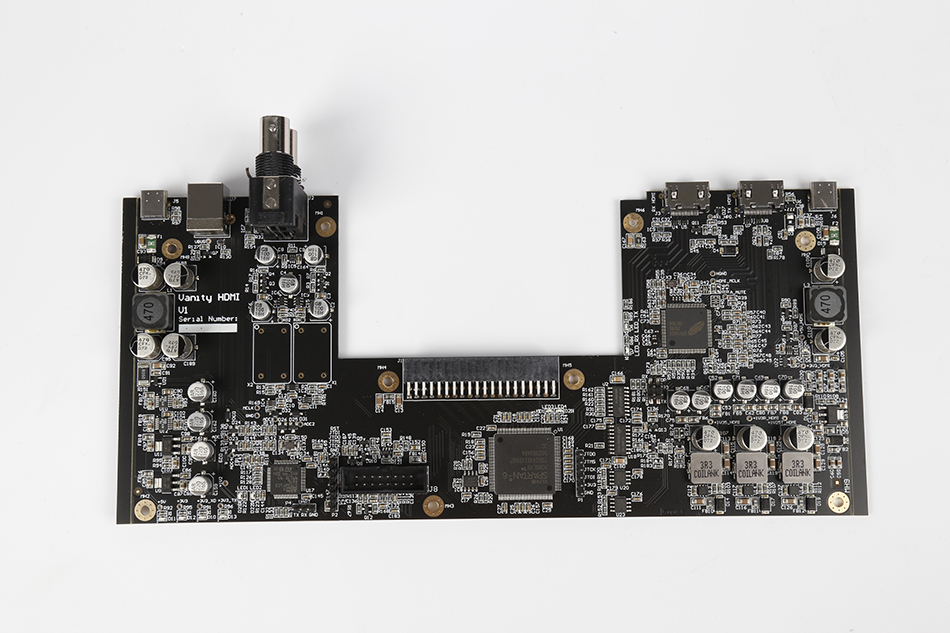

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 28. 2025, 14:06:04

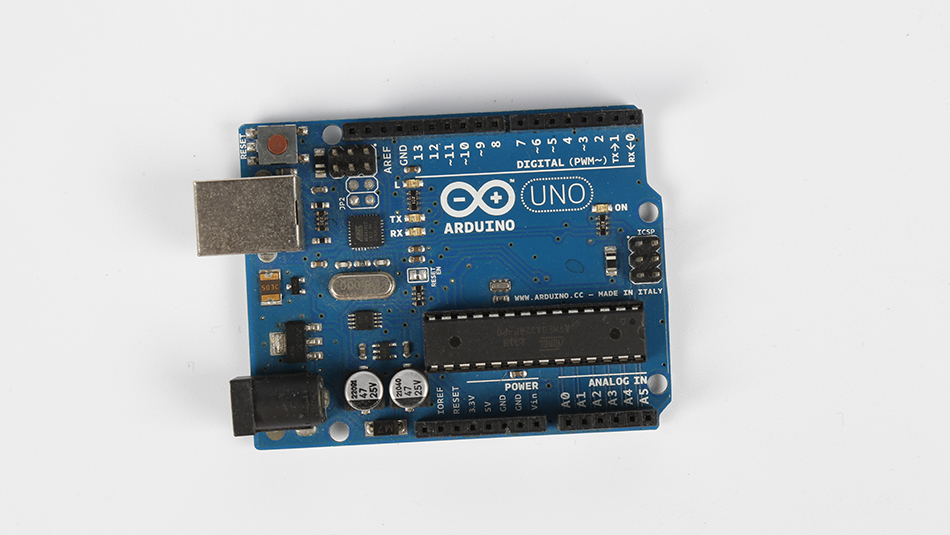

Printed Circuit Boards (PCBs) are the backbone of nearly every electronic device we use today. As technology advances, the demand for smaller, more powerful, and efficient electronics grows. This need has led to innovative techniques in PCB design and manufacturing, such as the use of blind and buried vias. In this article, we'll explore what blind and buried vias are, their significance in PCB assembly, and how they enhance the capabilities of modern electronics.

Before diving into blind and buried vias, it's essential to understand what vias are in the context of PCB design. Vias are small conductive pathways that allow electrical connections between different layers of a PCB. These pathways are crucial for routing signals and power throughout the board.

There are three primary types of vias used in PCB design:

Through-Hole Vias: These vias run from the top layer to the bottom layer of the PCB. They are the most common type and are used in traditional PCB designs.

Blind Vias: These vias connect an outer layer of the PCB to one or more inner layers but do not extend through the entire board.

Buried Vias: These vias connect two or more inner layers of the PCB and are not visible from the outer layers.

One of the primary reasons for using blind and buried vias is to save space. As PCBs become more complex, designers must fit more components and connections into smaller areas. Blind and buried vias allow for more routing options without increasing the board's size. This efficiency is crucial for compact devices like smartphones and wearables.

Maintaining signal integrity is vital in high-speed and high-frequency circuits. Blind and buried vias can help reduce the length of signal paths, minimizing signal loss and potential interference. This advantage is particularly important in RF (radio frequency) and microwave applications.

Heat dissipation is a significant concern in PCB design. Blind and buried vias can aid in thermal management by providing additional pathways for heat to move away from critical components. This capability helps prevent overheating and ensures the longevity and reliability of the device.

The inclusion of blind and buried vias adds complexity to the PCB manufacturing process. Here's a step-by-step look at how these vias are typically incorporated into PCB assembly:

The process begins with designing the PCB layout using specialized software. The designer specifies the placement of blind and buried vias based on the circuit's needs and the available space.

In PCBs with blind and buried vias, the board is constructed in layers. The manufacturer decides the layer stack-up, which is the order and number of layers in the PCB. This decision is crucial for determining where blind and buried vias can be placed.

Once the design is finalized, the board undergoes a drilling process to create the vias. For blind and buried vias, this step is more intricate because it involves precise drilling to specific depths. After drilling, the vias are plated with a conductive material, typically copper, to establish electrical connections between layers.

After plating, the individual layers are laminated together to form the complete PCB. This process ensures that all vias are securely integrated into the board, maintaining the necessary connections.

Finally, the PCB undergoes rigorous testing to ensure that all connections, including those made by blind and buried vias, are functioning correctly. Quality control is critical to catch any defects that could affect the board's performance.

Incorporating blind and buried vias can increase the cost of PCB manufacturing. The additional design complexity, precise drilling, and extra steps in the assembly process contribute to higher expenses. However, the benefits in terms of performance and space savings often justify the added cost.

Designing PCBs with blind and buried vias requires careful planning and expertise. Designers must consider factors like thermal expansion, signal integrity, and manufacturability. Collaborating closely with the manufacturing team can help mitigate potential issues.

While blind and buried vias offer significant advantages, they are not suitable for all PCB designs. Their use depends on the specific requirements of the circuit and the capabilities of the manufacturing process. Designers must weigh the benefits against the limitations to determine if these vias are the right choice for their project.

Blind and buried vias are powerful tools in modern PCB design and manufacturing. By providing more efficient use of space, enhancing signal integrity, and aiding in thermal management, these vias enable the creation of smaller, faster, and more reliable electronic devices. As technology continues to advance, the role of blind and buried vias in PCB assembly will undoubtedly grow, paving the way for even more innovative electronics. Whether you're a designer, manufacturer, or enthusiast, understanding the impact of blind and buried vias is essential in the ever-evolving world of electronics.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB