-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 22. 2025, 19:15:07

In the rapidly evolving world of electronics, precision is key. One area where precision truly matters is in Ball Grid Array (BGA) assembly services. BGA assembly is a crucial part of manufacturing electronic components, ensuring that devices function correctly and efficiently. In this article, we'll explore what precision BGA assembly services are, why they're important, and how they impact the electronics industry.

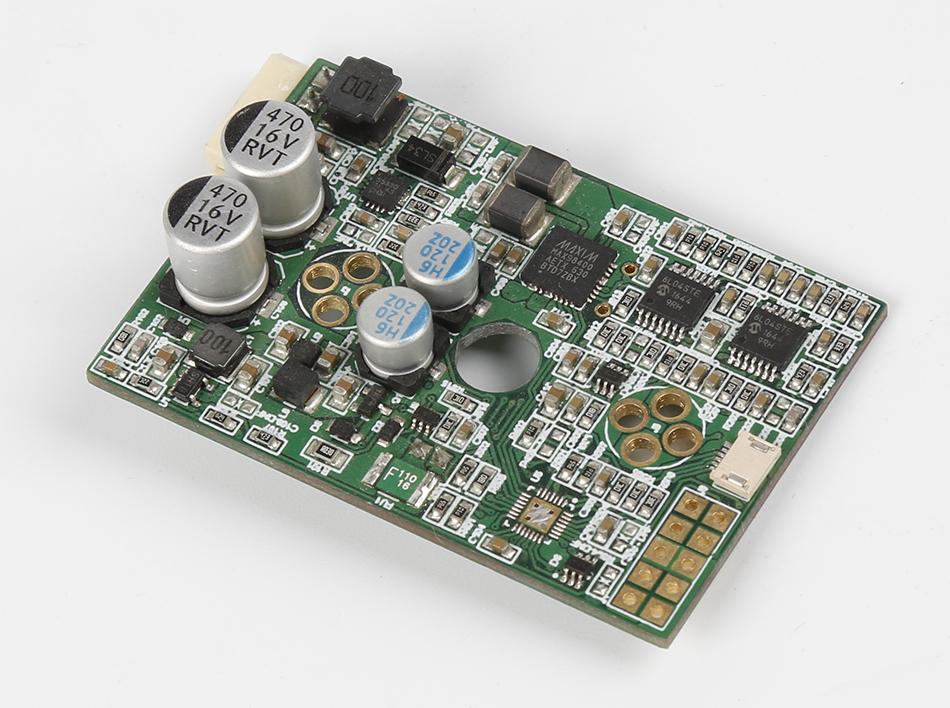

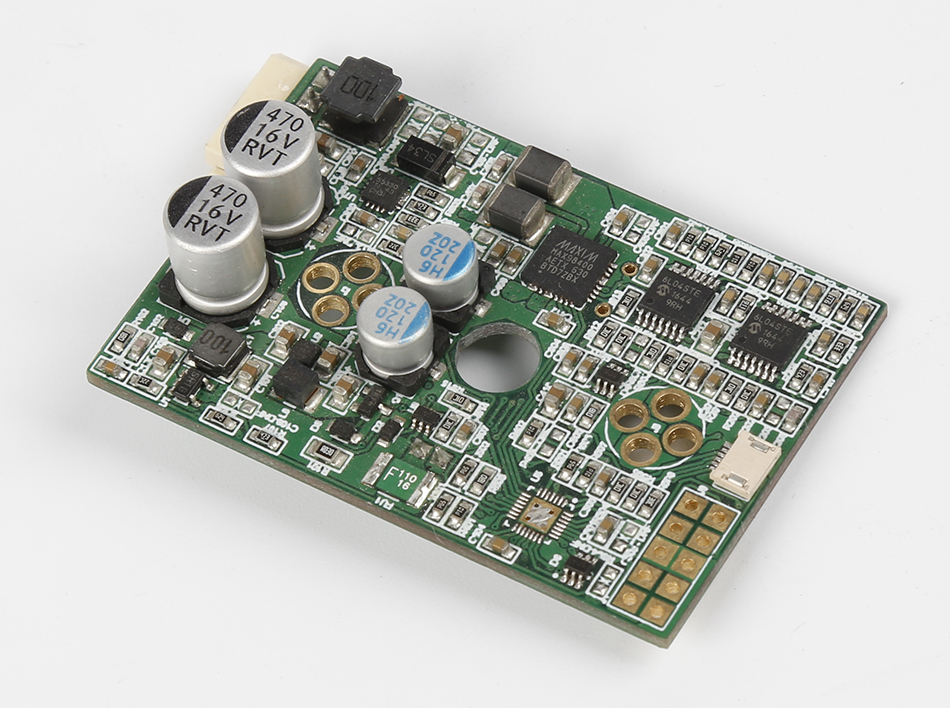

Ball Grid Array, or BGA, is a type of surface mount packaging used for integrated circuits. It uses an array of small balls of solder to create electrical connections between a chip and a printed circuit board (PCB). BGA packages are known for their ability to provide more interconnection pins than other types of packages, which is essential for high-performance applications.

Precision in BGA assembly is critical. The solder balls must be accurately placed and correctly melted to form reliable connections. Even the smallest error can lead to failures in the electronic device, causing significant issues down the line. Precision ensures that each component is correctly aligned and connected, which enhances the overall performance and reliability of the device.

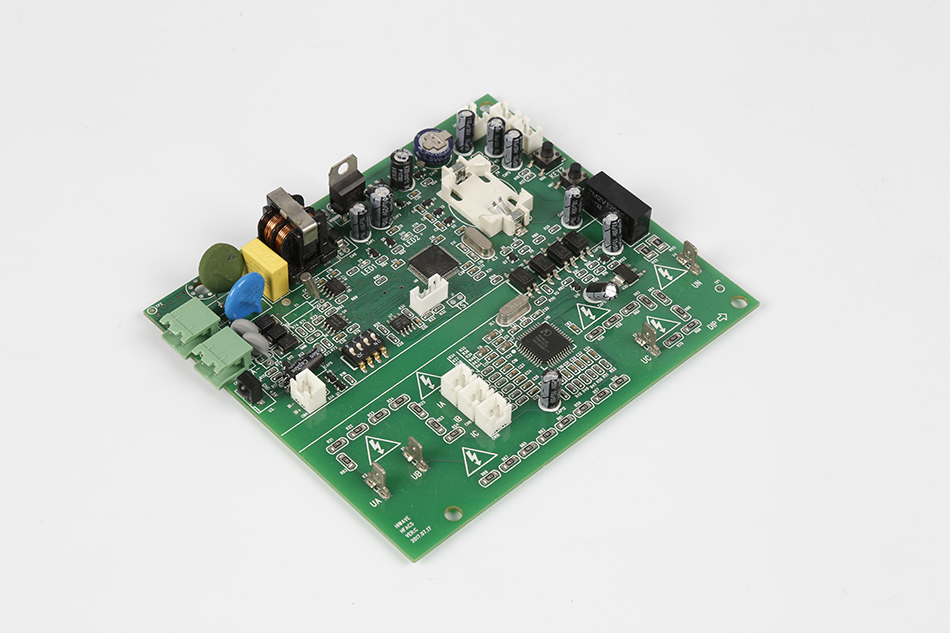

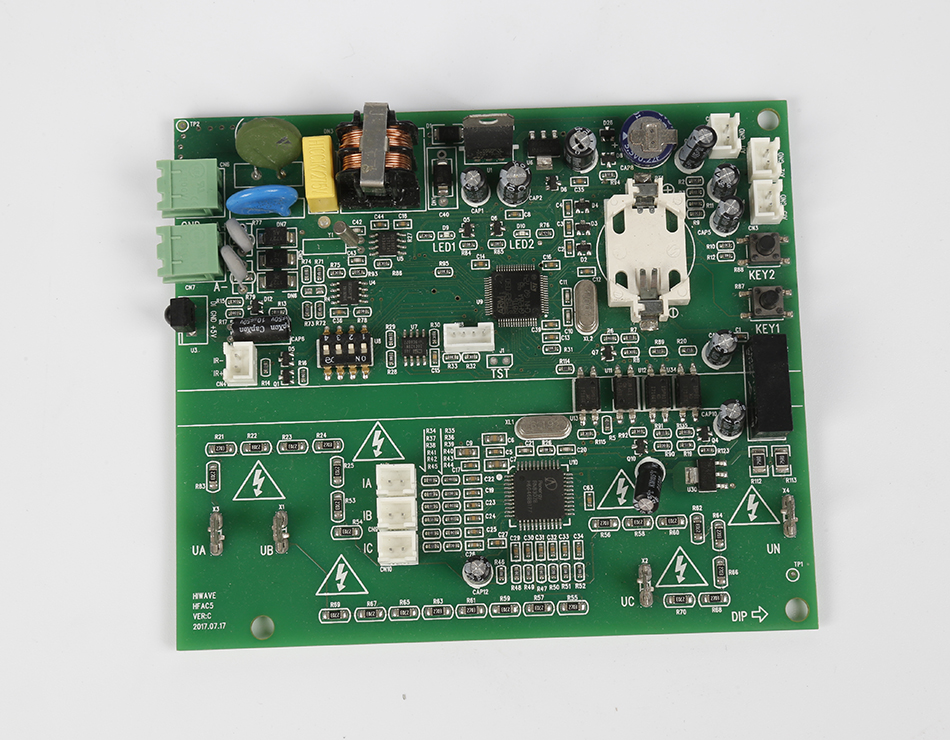

The BGA assembly process begins with preparing the PCB. This involves cleaning the board to remove any contaminants that might interfere with the soldering process. The board is then inspected to ensure it's free of defects.

Once the PCB is ready, solder paste is applied to the pads where the BGA will be placed. This paste is a mixture of tiny solder balls and flux, which helps the solder to flow and bond during the reflow process.

The BGA is then placed onto the PCB. This step requires extreme precision, as the alignment of the BGA with the PCB pads is crucial for the integrity of the connections. Automated machines equipped with vision systems are typically used to ensure precise placement.

After placement, the assembly goes through a reflow oven. The heat from the oven melts the solder paste, causing it to flow and form a solid connection between the BGA and the PCB. The reflow process is carefully controlled to prevent defects like solder bridging or insufficient solder joints.

The final step in the BGA assembly process is inspection and testing. Advanced imaging techniques, such as X-ray inspection, are used to examine the solder joints for defects. Functional testing may also be conducted to ensure the component works as intended.

Precision in BGA assembly leads to higher performance and reliability of electronic devices. When components are perfectly aligned and connected, they are less likely to fail, which means fewer returns and repairs.

As technology advances, devices are becoming smaller and more powerful. Precision BGA assembly allows manufacturers to pack more functionality into smaller packages, enabling the miniaturization of electronics without compromising performance.

While precision assembly may seem more costly initially, it can save money in the long run. By reducing the risk of defects and failures, companies can decrease the costs associated with returns, repairs, and warranty claims.

When selecting a BGA assembly service provider, it's important to consider several factors to ensure you receive the highest quality service.

Look for a provider with a proven track record in precision electronics assembly. Experienced providers have the knowledge and skills necessary to handle complex assemblies and ensure high-quality results.

The best BGA assembly service providers use state-of-the-art technology and equipment. This includes automated placement machines, advanced reflow ovens, and cutting-edge inspection tools to guarantee precision and reliability.

A strong quality control process is essential for precision BGA assembly. Providers should have rigorous testing and inspection procedures in place to identify and rectify any issues before the product reaches the market.

Excellent customer support is crucial. Choose a provider that communicates clearly and is responsive to your needs, ensuring a smooth and successful assembly process.

As technology continues to advance, the demand for precision BGA assembly services is expected to grow. With the rise of IoT devices, 5G technology, and other innovations, the need for precise, reliable electronic components will only increase. Companies that invest in precision BGA assembly today will be well-positioned to meet the demands of tomorrow's electronics market.

In conclusion, precision BGA assembly services play a vital role in the electronics industry, providing the accuracy and reliability needed for modern devices. By understanding the BGA manufacturing process and the benefits of precision assembly, businesses can make informed decisions when choosing an assembly service provider. With the right partner, companies can ensure their products meet the highest standards of quality and performance.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB