-

- PCB TYPE

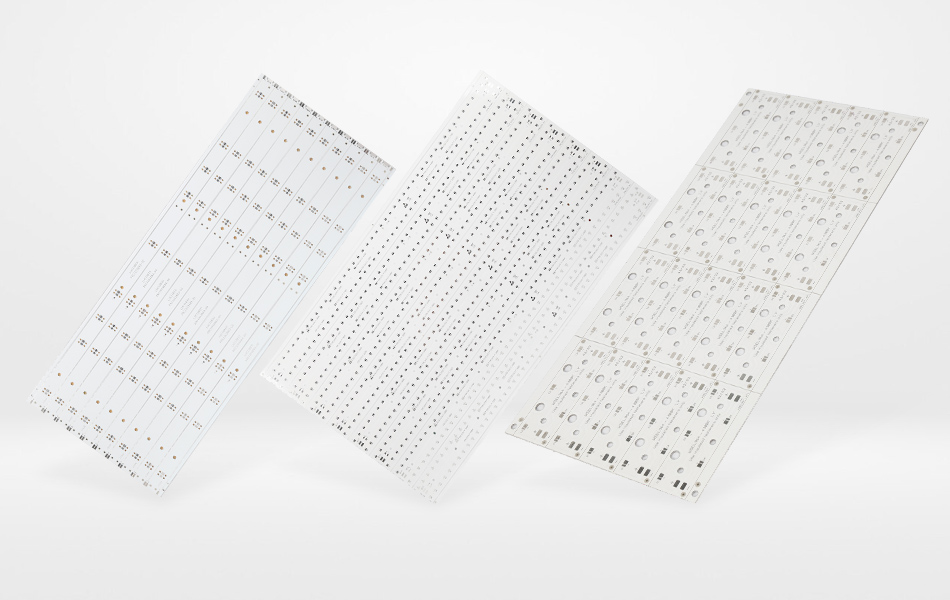

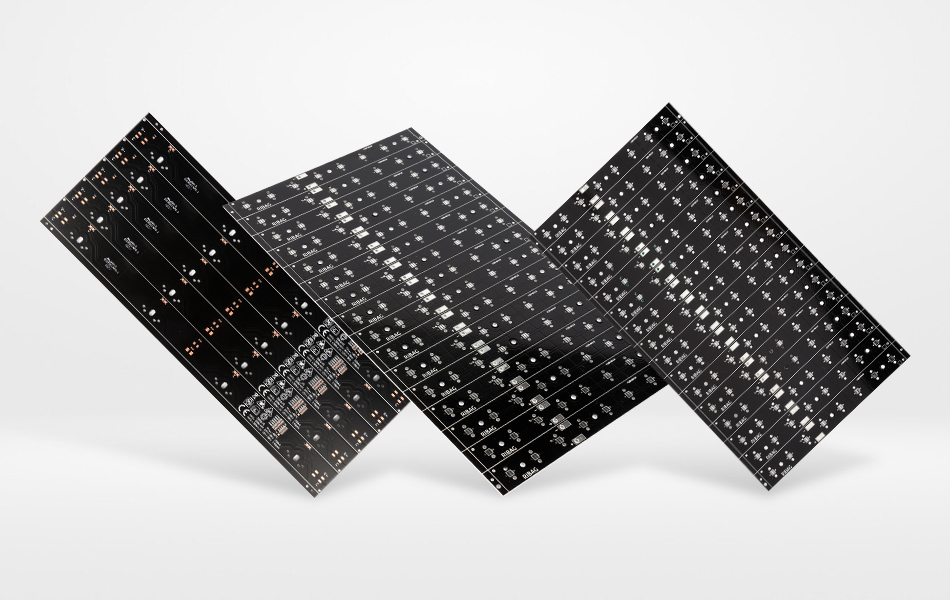

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 08. 2025, 10:41:23

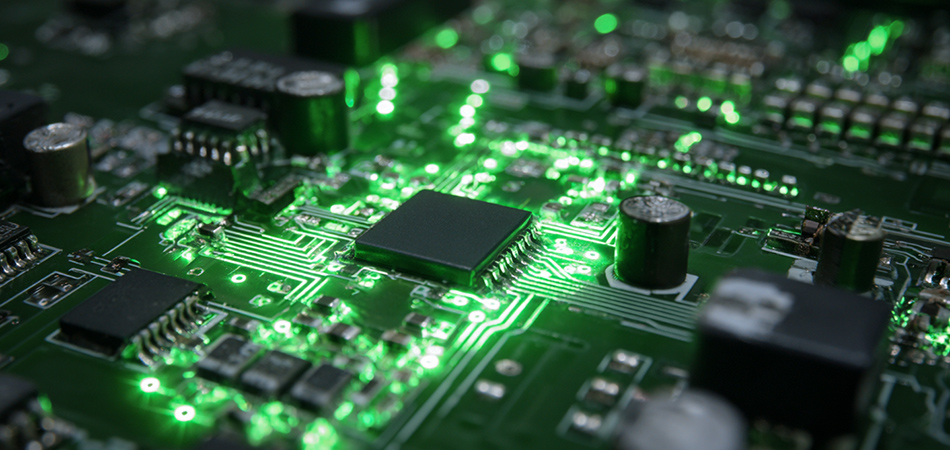

In the dynamic landscape of modern electronics, double layer aluminum printed circuit boards (PCBs) have emerged as a pivotal technology, balancing thermal efficiency, mechanical robustness, and cost - effectiveness. These PCBs are engineered to meet the escalating demands of high - power, space - constrained applications, making them indispensable across industries from lighting to automotive and beyond. This article provides an in - depth exploration of double layer aluminum PCBs, covering their structural design, material science, manufacturing processes, real - world applications, and emerging industry trends.

Fundamentals of Double Layer Aluminum PCBs

Structural Design and Core Components

A double layer aluminum PCB features a three - layer architecture: a central aluminum substrate sandwiched between two copper conductive layers, separated by a dielectric material. The aluminum substrate, the defining component, serves dual roles as a mechanical support structure and a thermal dissipater. Its high thermal conductivity creates an efficient pathway for heat generated by components, while its mechanical properties offer resistance to bending and impact.

The top copper layer is dedicated to component placement and signal routing, accommodating both surface - mount and through - hole components. The bottom copper layer typically functions as a ground plane or power distribution layer, providing a stable electrical reference and reducing electromagnetic interference (EMI). The dielectric layer, whether ceramic - filled epoxy or polyimide, insulates the copper layers while facilitating heat transfer to the aluminum base, ensuring a balance between electrical isolation and thermal performance.

Key Advantages for Modern Electronics

Thermal Efficiency: The aluminum substrate efficiently dissipates heat from power - intensive components like LEDs, MOSFETs, and microprocessors, preventing thermal stress that could degrade performance or cause failure. This is critical in applications where consistent operating temperatures are non - negotiable.

Mechanical Durability: Aluminum’s inherent strength and fatigue resistance make these PCBs suitable for harsh environments, such as those with high vibrations (automotive) or frequent thermal cycling (industrial controls).

Design Flexibility: The two - layer configuration allows for straightforward routing of signals and power, making it easier to prototype and iterate designs. This simplicity also reduces manufacturing complexity compared to multi - layer boards, lowering costs and lead times.

Cost - Benefit Balance: While offering superior thermal performance to traditional FR4 PCBs, double layer aluminum PCBs remain more economical than complex multi - layer metal - core alternatives, making them ideal for mid - to high - power applications without excessive design complexity.

Material Selection for Optimal Performance

Aluminum Substrate Alloys

The choice of aluminum alloy significantly impacts PCB performance. 6xxx series alloys (e.g., 6061, 6063) are most common due to their balanced properties:

6061 - T6: Combines high thermal conductivity with excellent mechanical strength, suitable for industrial and automotive applications where both heat management and vibration resistance are critical.

6063: Offers better formability for intricate shapes, making it a preferred choice for LED lighting fixtures and consumer electronics requiring compact, custom designs.

Substrate thickness is application - dependent: thinner substrates (0.8–1.6mm) prioritize portability and space efficiency, while thicker variants (2.0–3.0mm) enhance heat capacity for high - power devices like motor drives.

Dielectric Layer Options

Ceramic - Filled Epoxies: Widely used for their cost - effectiveness and moderate thermal conductivity (1.5–2.5 W/mK). These materials strike a balance between electrical insulation and heat transfer, making them suitable for most commercial applications, from LED panels to power supplies.

Polyimide Dielectrics: Chosen for high - temperature environments (up to 250°C), such as aerospace avionics or under - hood automotive electronics. They offer superior electrical insulation and resistance to thermal degradation, albeit at a higher cost.

Copper Layers and Surface Finishes

Copper layers, typically 1–2 oz for signal traces and 3–4 oz for power paths, ensure low - resistance current flow. Surface finishes protect copper from oxidation and enhance solderability:

ENIG (Electroless Nickel Immersion Gold): Provides a smooth, corrosion - resistant surface ideal for fine - pitch components and high - reliability applications like medical devices.

OSP (Organic Solderability Preservative): A thin, eco - friendly coating suitable for lead - free soldering in consumer electronics, where cost and miniaturization are key.

HASL (Hot Air Solder Leveling): A traditional finish offering excellent solderability for through - hole components, commonly used in industrial and automotive PCBs.

Design Considerations for Double Layer Aluminum PCBs

Thermal Management Strategies

Component Placement and Thermal Vias

Heat - generating components should be positioned on the top layer, directly above thermal vias that connect to the aluminum substrate. Vias, strategically placed in a grid pattern around high - power devices, create direct thermal pathways, reducing thermal resistance. The number and size of vias depend on the component’s power dissipation: densely packed vias for high - wattage LEDs, for example, ensure efficient heat spreading across the aluminum base.

Heat Sink Integration

For applications requiring enhanced thermal performance, the bottom copper layer can be bonded to a heat sink or thermal pad. This configuration is common in LED floodlights or server power supplies, where the aluminum substrate acts as a heat spreader, distributing heat to the external sink and maintaining component temperatures within safe limits.

Electrical Design Best Practices

Signal Routing and Impedance Control

High - speed signals on the top layer require controlled impedance routing to maintain signal integrity. Traces should be spaced to avoid crosstalk, with the bottom layer serving as a solid ground plane to minimize EMI. For example, in wireless communication modules, 50Ω impedance traces ensure stable signal transmission, supported by the grounding plane’s noise - filtering properties.

Power Distribution Design

Power traces on both layers must be wide enough to handle current loads without excessive voltage drop. Inverter circuits, for instance, require robust power paths on the bottom layer, complemented by decoupling capacitors on the top layer to stabilize voltage supply and reduce switching noise.

Mechanical Design for Durability

Mounting and Form Factor

Mounting holes should be placed at stress - free zones, away from component clusters, to prevent substrate cracking. Reinforced annular rings around holes enhance mechanical stability, crucial in automotive ECUs subject to constant vibration. The PCB’s form factor is optimized for enclosure fit, with edge clearances ensuring compatibility with clips, brackets, or adhesive mounts.

Environmental Protection

Conformal coatings (acrylic or silicone) are applied to both layers to protect against moisture, dust, and chemicals, especially in outdoor LED lighting or marine electronics. The aluminum substrate’s natural corrosion resistance, combined with coating, ensures long - term reliability in harsh environments.

Manufacturing Processes for Double Layer Aluminum PCBs

Substrate Preparation and Lamination

Aluminum Cutting: CNC milling or laser cutting ensures precise dimensions, followed by surface treatment (degreasing, micro - etching) to enhance dielectric adhesion.

Dielectric Lamination: High - pressure lamination (100–150°C, 50–100 psi) bonds the dielectric layer to the aluminum substrate, ensuring a void - free interface critical for thermal conductivity.

Copper Layer Fabrication

Foil Lamination: Electrolytic copper foil is bonded to both dielectric surfaces using thermoset adhesives, providing a smooth base for circuit patterns.

Photolithography and Etching: Circuit designs are transferred via photoresist exposure, with unwanted copper etched away to form traces. Laser direct imaging (LDI) is increasingly used for fine - pitch applications, improving pattern accuracy.

Via and Hole Formation

Drilling: Mechanical drilling for standard vias and mounting holes; laser drilling for microvias (≤0.3mm), essential for high - density component placement.

Plating: Vias are plated with copper to ensure electrical connectivity between layers, with thickness controlled to optimize thermal and electrical performance.

Surface Finishing and Assembly

Surface Treatment: Automated lines apply HASL, ENIG, or OSP finishes, with flux removal and cleaning to ensure solderability.

Component Assembly: Pick - and - place machines mount components, followed by reflow soldering for surface - mount devices or wave soldering for through - hole components, ensuring secure mechanical and electrical connections.

Quality Assurance and Testing Protocols

Material and Process Inspection

Incoming Inspection: Aluminum substrates are tested for flatness, alloy composition, and thermal conductivity. Copper foil is checked for thickness uniformity and surface defects.

In - Process Checks: AOI systems verify trace widths, via alignment, and solder joint quality. X - ray inspection detects voids in lamination or plating inconsistencies.

Performance Testing

Electrical Testing: Continuity tests ensure no open circuits or shorts; impedance analyzers verify signal trace characteristics. High - voltage tests (500V DC) check dielectric integrity between layers.

Thermal Testing: Infrared thermography maps temperature distribution under load, identifying hotspots. Thermal cycling (-40°C to +85°C) tests solder joint durability and substrate stability.

Mechanical Testing: Vibration tests (10–2000Hz) and bend radius measurements ensure the PCB withstands operational stresses without trace cracking.

Industrial Applications of Double Layer Aluminum PCBs

LED Lighting Solutions

Double layer aluminum PCBs are the backbone of modern LED fixtures:

Commercial Lighting: In linear LED panels, the aluminum substrate dissipates heat from dense LED arrays, ensuring uniform light output and 50% longer lifespan compared to FR4 PCBs.

Automotive Lighting: Headlights and taillights use these PCBs to manage heat from high - power LEDs, with the mechanical strength to withstand engine bay vibrations and temperature fluctuations.

Architectural Lighting: Custom - shaped PCBs enable curved or recessed fixtures, with thermal vias ensuring efficient heat dissipation in compact, aesthetic designs.

Power Electronics and Energy Systems

DC - DC Converters: The dual - layer design supports high - current paths on the bottom layer, while the top layer routes control signals, with the aluminum substrate preventing overheating in renewable energy inverters.

Battery Management Systems (BMS): In electric vehicles, these PCBs monitor battery cells, with thermal management critical to preventing thermal runaway and ensuring safe operation.

Automotive Electronics

Engine Control Units (ECUs): Exposed to extreme temperatures and vibrations, double layer aluminum PCBs provide stable operation for microprocessors and sensors, with HASL finishes resisting oil and coolant exposure.

Advanced Driver - Assistance Systems (ADAS): High - speed signal routing on the top layer, combined with a grounded bottom layer, ensures reliable data transmission for cameras and radar modules, while the aluminum substrate dissipates heat from image processors.

Consumer Electronics

Portable Devices: Laptops and tablets use thin aluminum PCBs to manage heat from multi - core processors, enabling slim designs without compromising performance.

Wearable Tech: Smartwatches and fitness trackers rely on lightweight double layer PCBs, with thermal vias preventing overheating during continuous use.

Emerging Trends in Double Layer Aluminum PCB Technology

Miniaturization and High - Density Integration

Advances in manufacturing, such as laser - drilled microvias and HDI technology, allow for smaller component spacing and finer traces, enabling double layer PCBs to compete in high - density applications previously dominated by multi - layer boards. This trend is particularly evident in IoT sensors and compact industrial controllers.

Sustainable Manufacturing Practices

Eco - Friendly Materials: Recycled aluminum substrates and water - based dielectric adhesives reduce environmental impact, aligning with global sustainability goals.

Energy - Efficient Processes: Low - temperature lamination and lead - free HASL finishes minimize energy consumption and hazardous waste, meeting RoHS and REACH compliance.

Integration with Advanced Thermal Solutions

Hybrid Substrates: Combining aluminum with graphite or carbon fiber layers enhances thermal conductivity (300+ W/mK), enabling higher power densities in compact designs, such as 5G small cells and high - performance computing modules.

Active Cooling Integration: Micro - channel cooling systems embedded within the aluminum substrate provide liquid - cooled solutions for extreme power applications, such as server rack power supplies.

Automation and Industry 4.0

AI - powered design tools optimize thermal via placement and trace routing, reducing design time by 30%. Robotic assembly lines with real - time quality monitoring ensure consistent manufacturing, critical for high - volume automotive and consumer electronics production.

Conclusion

Double layer aluminum PCBs represent a harmonious blend of thermal, mechanical, and electrical engineering, addressing the core challenges of modern electronics: heat management, durability, and cost - efficiency. Their versatility makes them a staple in industries ranging from lighting to automotive, while ongoing advancements in materials and manufacturing position them at the forefront of miniaturization and sustainability trends. As electronic devices continue to demand higher power in smaller forms, double layer aluminum PCBs will remain a foundational technology, enabling innovation across sectors and ensuring reliable performance in even the most demanding environments. By balancing design simplicity with robust functionality, these PCBs are not just components—they are enablers of the next generation of electronic innovation.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB