-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 05. 2025, 12:43:35

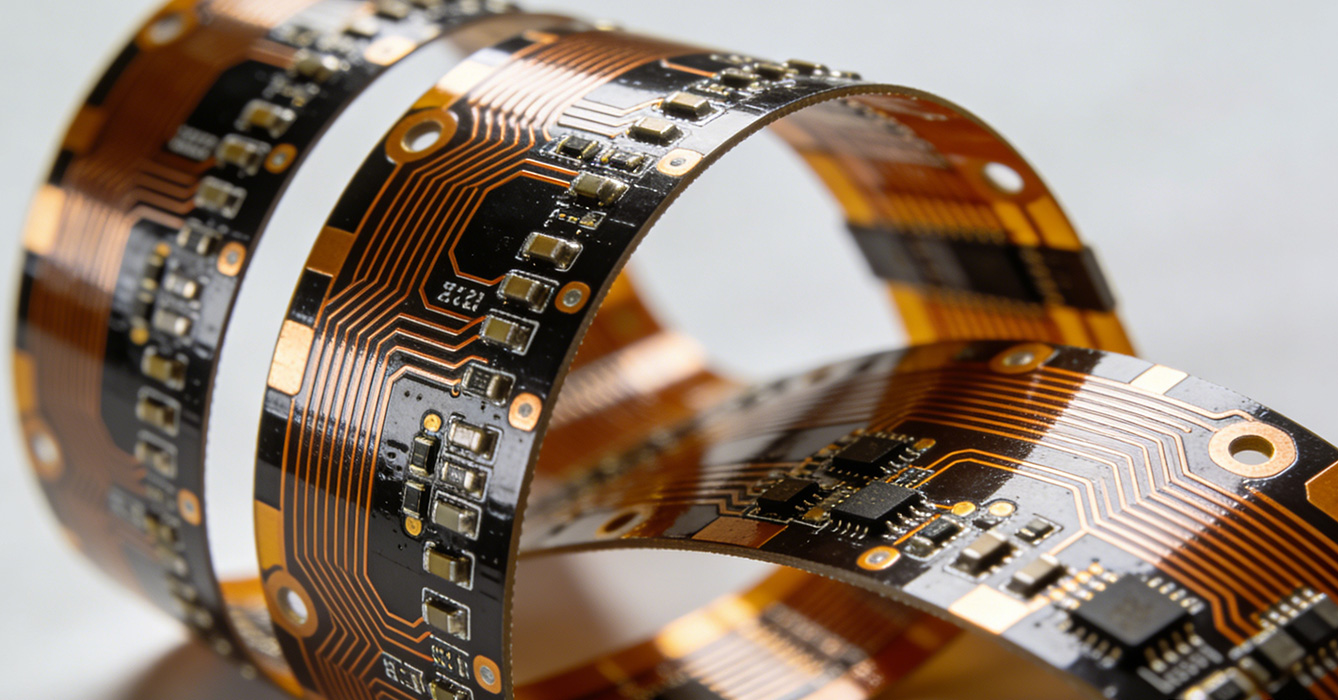

As the global electronics industry evolves toward miniaturization, intelligence, and flexibility, a professional FPC manufacturer has emerged as a foundational pillar of the electronics ecosystem. Unlike niche FPC suppliers focused on single industries, top FPC manufacturers distinguish themselves through exceptional cross-industry adaptability and integrated technological capabilities, tailoring flexible printed circuit (FPC) solutions to the unique demands of industrial automation, medical devices, automotive electronics, and consumer gadgets. These manufacturers are not just component producers—they are strategic partners that bridge material science, process engineering, and industry-specific requirements to deliver reliable, high-performance FPCs. For enterprises across diverse sectors seeking to innovate electronic products, partnering with a versatile FPC manufacturer is critical to unlocking design flexibility, enhancing product reliability, and gaining a competitive edge in global markets.

The ability to adapt FPC technology to diverse industry needs is the key differentiator of top FPC manufacturers, enabling them to serve a broad spectrum of electronic applications:

- Industrial Automation & Robotics: For industrial control systems, robotic arms, and smart factory sensors, FPC manufacturers develop ruggedized FPCs resistant to dust, vibration, and extreme temperatures. These FPCs feature enhanced mechanical strength, anti-interference shielding, and reliable signal transmission, ensuring stable operation in harsh industrial environments where downtime is costly. Modular FPC designs also facilitate easy integration with complex industrial equipment.

- Medical Devices: In implantable sensors, surgical robots, and portable diagnostic tools, FPC manufacturers prioritize biocompatibility, miniaturization, and long-term reliability. They use medical-grade substrates and precision bonding technologies (e.g., gold ball bonding) to create ultra-thin, corrosion-resistant FPCs that comply with strict regulatory standards (ISO 13485). These FPCs support life-critical functions by ensuring stable signal transmission and biocompatibility with human tissue.

- Automotive & New Energy Vehicles (NEV): For automotive ADAS systems, battery management systems (BMS), and in-vehicle infotainment, FPC manufacturers produce high-temperature-resistant, flame-retardant FPCs. These FPCs withstand automotive environmental stressors (temperature fluctuations, vibration, chemical exposure) and comply with IATF 16949 standards. Advanced FPC solutions also support NEV’s high-voltage power distribution and energy efficiency requirements.

- Consumer Electronics: Beyond smartphones, FPC manufacturers cater to wearables, VR/AR devices, and home appliances with ultra-thin, flexible FPCs. These FPCs enable compact, lightweight designs while supporting high-frequency connectivity (e.g., Wi-Fi 6E, Bluetooth 5.3) and dynamic bending for foldable/wearable products. Rapid customization capabilities also match the fast iteration cycle of consumer electronics.

Leading FPC manufacturers drive industry progress through integrated technological innovation, combining multi-disciplinary expertise to overcome technical bottlenecks:

- Material & Process Co-Innovation: Manufacturers collaborate with material suppliers to develop advanced substrates (e.g., high-Tg polyimides, bio-based films) and optimize processes (e.g., laser drilling, precision lamination) for specific applications. This synergy ensures FPCs balance flexibility, strength, and performance—for example, low-loss materials for high-frequency industrial communication or biocompatible films for medical devices.

- Digital & Smart Manufacturing Integration: To enhance efficiency and quality, FPC manufacturers adopt digital twin technology, AI-driven inspection systems, and cloud-based traceability platforms. Digital twins simulate production processes to predict defects, while AI-powered 3D AOI and X-ray testing detect micro-defects in FPCs. Cloud traceability ensures full visibility of raw materials, production parameters, and quality data across global facilities.

- Hybrid FPC Integration: Innovating hybrid FPC solutions that combine flexible and rigid segments (rigid-flex FPCs) or integrate passive components (e.g., resistors, capacitors) directly onto FPCs. These integrated solutions reduce component count, save space, and improve reliability, making them ideal for compact, high-integration applications like miniaturized medical sensors and automotive microcontrollers.

As FPCs are used in critical applications worldwide, top FPC manufacturers adhere to rigorous global compliance and quality standards:

- Multi-Standard Compliance: Manufacturers comply with industry-specific standards (IPC-6012/2221 for FPC quality, RoHS/REACH for environmental protection) and regional regulations (FDA for medical, CE for European markets). This global compliance enables their FPCs to enter diverse international markets, supporting customers’ global expansion strategies.

- Full-Lifecycle Quality Control: Implementing end-to-end quality management systems, from raw material incoming inspection to final product validation. Key tests include thermal cycling, flex endurance, signal integrity, and corrosion resistance testing. Strict batch traceability allows rapid defect localization and resolution, ensuring consistent quality across high-volume production.

Forward-looking FPC manufacturers adopt proactive strategies to address emerging industry trends:

- Sustainable Manufacturing: Investing in eco-friendly materials (recyclable substrates, water-based adhesives) and energy-efficient production processes to reduce carbon footprint. This supports customers’ sustainability goals and aligns with global carbon neutrality trends.

- Emerging Technology Layout: Pre-emptively developing FPC solutions for emerging fields such as IoT sensors, 6G communication, and quantum computing. These solutions focus on ultra-low power consumption, high-bandwidth signal transmission, and compatibility with miniaturized quantum components.

In conclusion, a professional FPC manufacturer is a versatile enabler of cross-industry electronic innovation, leveraging cross-sector adaptability, integrated technology, and global quality compliance to support diverse customer needs. As the electronics industry continues to advance toward intelligence and flexibility, the role of FPC manufacturers in bridging technological gaps and driving sustainable innovation will become increasingly vital. For enterprises aiming to lead in their respective sectors, partnering with a forward-thinking FPC manufacturer is a strategic investment in product quality, innovation capability, and global market competitiveness.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB