-

- PCB TYPE

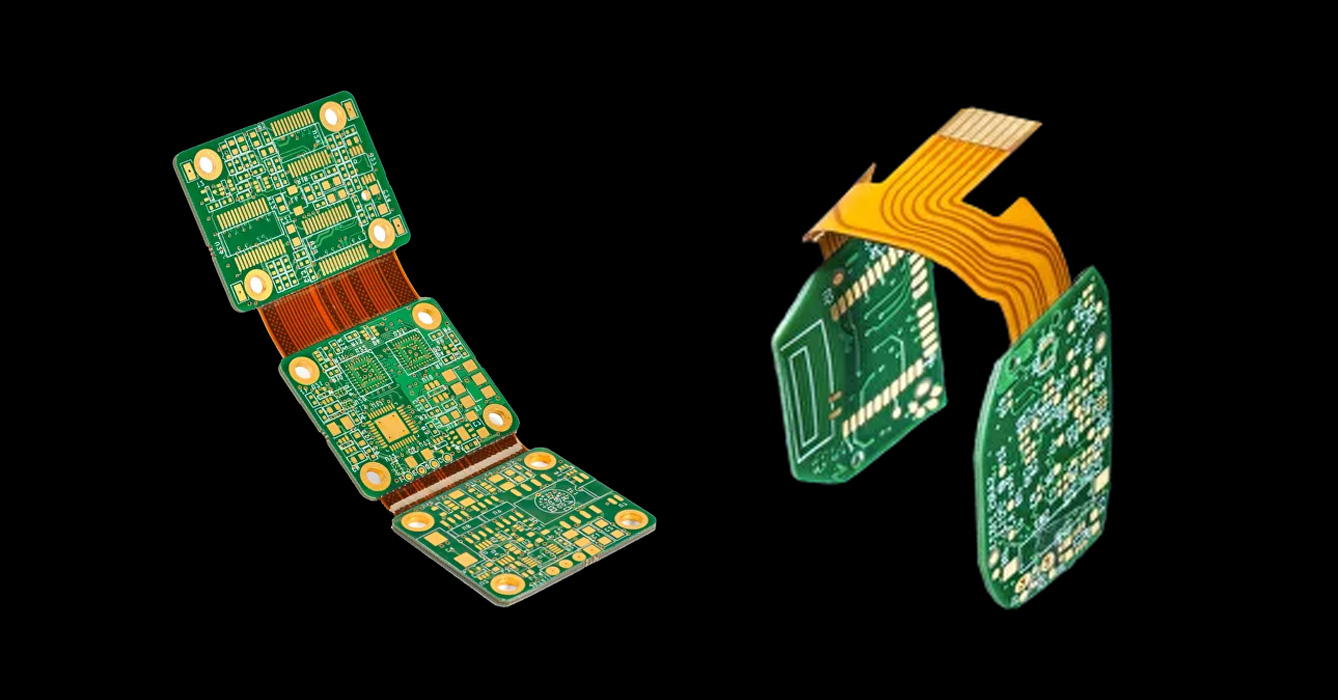

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 08. 2025, 13:03:14

In the era of Industry 4.0 and intelligent manufacturing, a professional FPC manufacturer is no longer confined to traditional component production but evolves into a digital-driven partner that empowers the entire electronics industry’s smart upgrading. By integrating advanced digital technologies into every link of FPC design, production, and service, these manufacturers break through the limitations of traditional manufacturing, achieving higher efficiency, better quality, and deeper collaboration with customers. Unlike manufacturers stuck in conventional processes, a forward-looking FPC manufacturer focuses on digital transformation and smart ecosystem building, enabling seamless connection with customers’ intelligent product development and production systems. For electronics enterprises pursuing high efficiency, innovation, and intelligent upgrading, partnering with a digitally transformed FPC manufacturer is a crucial strategic choice to gain a competitive edge in the global market.

The digital transformation of FPC manufacturers is supported by three core pillars, which together build a smart manufacturing system with high flexibility and efficiency:

- Smart Production & Process Digitization: Leading FPC manufacturers adopt fully digital production lines, integrating IoT sensors, automated equipment, and AI-driven control systems. IoT sensors real-time monitor key production parameters (e.g., temperature, pressure, humidity) to ensure process stability; automated equipment (e.g., laser drilling machines, precision placement machines) realizes unmanned operation of core processes, reducing human errors; AI algorithms analyze production data to optimize process parameters dynamically, improving production yield and efficiency. Digital process management also enables full traceability of each production link, laying the foundation for quality control.

- Digital Twin & Virtual Simulation: By building digital twin models of FPC production lines and products, manufacturers can simulate the entire production process and product performance in a virtual environment. This technology allows for pre-verification of new product designs, prediction of potential production bottlenecks, and optimization of production schedules without affecting actual production. For example, when developing FPCs for new smart devices, digital twin simulation can quickly validate the compatibility of FPC designs with customer products, shortening the development cycle significantly.

- Data-Driven Decision-Making System: FPC manufacturers establish integrated data platforms that collect and analyze data from raw material procurement, production, quality inspection, and after-sales service. Big data analytics tools mine valuable insights from massive data, supporting scientific decision-making in production scheduling, material procurement, and technology upgrading. For instance, through analysis of quality inspection data, manufacturers can identify the root causes of common defects and take targeted improvement measures, continuously enhancing product quality.

Digitally transformed FPC manufacturers actively build smart ecosystems, realizing in-depth collaboration with upstream and downstream partners in the electronics industry:

- Digital Collaboration with Customers: Manufacturers provide customers with digital collaboration platforms, enabling real-time sharing of design data, production progress, and quality reports. Customers can track the production status of FPCs online and participate in the design optimization process remotely. This seamless digital collaboration breaks down geographical and temporal barriers, accelerating the iteration of new products and improving the matching degree between FPCs and customer needs.

- Upstream Supply Chain Digital Synergy: By connecting with raw material suppliers through digital platforms, FPC manufacturers achieve transparent management of the supply chain. They can real-time monitor the supply status of raw materials, predict potential supply risks, and optimize procurement plans. Digital supply chain collaboration also ensures the traceability of raw materials, enhancing the stability and reliability of the entire production chain.

- Empowering Customers’ Intelligent Product Development: Beyond providing FPC products, manufacturers leverage their digital capabilities to assist customers in developing intelligent products. For example, they provide FPC solutions integrated with sensor circuits and wireless communication modules, supporting customers in realizing intelligent functions such as status monitoring and remote control of their products. This value-added service transforms manufacturers from component suppliers to strategic partners in customers’ intelligent upgrading.

In the context of digital transformation, FPC manufacturers upgrade their quality control systems to digital and intelligent levels, ensuring product reliability in complex application scenarios:

- Intelligent Quality Inspection: Replacing traditional manual inspection with AI-driven visual inspection systems (e.g., 3D AOI, high-precision X-ray inspection), manufacturers can detect micro-defects (e.g., micro-cracks, uneven solder joints) in FPCs more accurately and efficiently. These intelligent inspection systems can also learn from inspection data continuously, improving inspection accuracy and adaptability to different product types.

- Full-Lifecycle Digital Quality Tracking: Establishing a full-lifecycle quality tracking system based on digital technologies, manufacturers record quality data of FPCs from raw material incoming to product delivery. Customers can query the quality information of each batch of FPCs through unique identification codes, ensuring full transparency of product quality. This system also enables rapid localization and handling of quality issues, reducing the impact on customers.

- Compliance Digitization Management: Digitizing the management of international standards and certifications (e.g., IPC, RoHS/REACH), manufacturers can real-time monitor compliance status and update relevant documents automatically. This ensures that FPC products meet the latest regulatory requirements in global markets, facilitating customers’ global market expansion.

Forward-looking FPC manufacturers leverage digital capabilities to lay out emerging technologies, preparing for the future development of the electronics industry:

- Integration with 6G & High-Speed Communication: With the impending arrival of 6G, manufacturers are developing FPC solutions adapted to high-frequency, high-speed communication scenarios through digital simulation and optimization. These FPCs feature low signal loss and high stability, supporting the development of next-generation intelligent communication devices.

- Exploration of Flexible Electronics & Wearable Technology: Combining digital twin technology and material science, manufacturers are exploring FPC applications in flexible electronics and wearable devices. They simulate the mechanical and electrical performance of FPCs under repeated bending and human-body-related environments, developing more durable and comfortable FPC solutions.

- Advancement of Green Digital Manufacturing: Integrating digital technologies with green manufacturing, manufacturers optimize production processes to reduce energy consumption and waste generation. For example, through digital scheduling, they minimize idle time of production equipment, improving energy utilization efficiency; through digital quality control, they reduce product scrap rates, promoting sustainable development.

In conclusion, digital transformation has become a core driving force for the development of FPC manufacturers, enabling them to achieve leapfrog development in production efficiency, product quality, and ecosystem collaboration. As the electronics industry continues to move toward intelligence and digitization, the role of digitally transformed FPC manufacturers in empowering industry upgrading will become increasingly prominent. For electronics enterprises aiming to lead the market, partnering with a forward-looking FPC manufacturer with advanced digital capabilities is a strategic investment in long-term innovation and development.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB