-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 27. 2025, 13:47:04

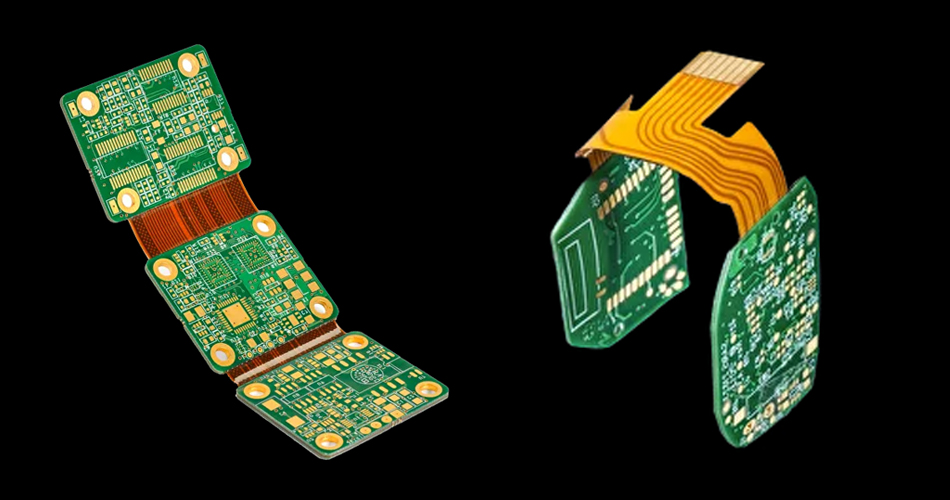

Flexible Printed Circuit (FPC) Fabrication has emerged as a transformative technology in modern electronics, redefining how devices are designed, manufactured, and deployed. Unlike rigid PCBs that limit form factor and placement, FPC fabrication produces lightweight, bendable circuits that adapt to complex shapes, tight spaces, and dynamic environments. This versatility makes FPCs indispensable for a wide range of applications—from wearables that conform to the human body to aerospace components that fit into curved structures. Beyond flexibility, FPC fabrication prioritizes efficiency, reliability, and adaptability, supporting the industry’s shift toward miniaturized, connected, and sustainable electronics. For engineers, manufacturers, and innovators, FPC fabrication is more than a manufacturing process; it’s a catalyst for reimagining what electronic devices can achieve.

FPC Fabrication delivers unique benefits that address the key challenges of modern electronics design:

Unmatched Design Flexibility: FPCs can bend, twist, and fold without compromising electrical performance, enabling engineers to create devices with unconventional shapes and compact footprints. This flexibility is a game-changer for products like foldable smartphones, wearable health monitors, and robotic arms, where rigid PCBs would be impractical or impossible to integrate.

Weight & Space Optimization: FPCs are significantly lighter and thinner than rigid PCBs, reducing overall device weight and freeing up space for other components. This is critical for applications like aerospace, automotive, and portable electronics, where every gram and millimeter counts toward performance and user experience.

Enhanced Reliability in Dynamic Environments: Unlike rigid PCBs, which are prone to damage from vibration, shock, or repeated movement, FPCs are designed to withstand mechanical stress. The flexible substrate and robust connections ensure consistent performance in applications like industrial automation, automotive powertrains, and medical devices that operate in dynamic or harsh conditions.

Simplified Assembly & Integration: FPC fabrication supports complex circuit layouts with fewer interconnections, reducing the number of components and assembly steps. This streamlines manufacturing, lowers production costs, and minimizes the risk of connection failures—critical for high-volume consumer electronics and safety-critical systems alike.

FPC Fabrication is a universal enabler, powering innovation across diverse sectors by addressing unique industry challenges:

Consumer Electronics: The backbone of foldable devices, wireless earbuds, and smartwatches, FPC fabrication enables sleek, user-centric designs that balance functionality with portability. It supports the integration of multiple sensors, batteries, and displays in compact spaces, driving the trend toward more immersive and versatile consumer gadgets.

Medical Technology: FPCs are revolutionizing medical devices by enabling minimally invasive tools, implantable sensors, and wearable health monitors. Their flexibility allows them to conform to anatomical structures, while their small size and biocompatible materials ensure safety and comfort for patients. FPC fabrication also supports the high reliability required for life-saving equipment like pacemakers and diagnostic scanners.

Automotive & Mobility: In electric vehicles (EVs) and advanced driver assistance systems (ADAS), FPC fabrication delivers lightweight, space-efficient circuits for powertrains, infotainment systems, and sensor arrays. FPCs fit into tight under-hood and cabin spaces, withstanding extreme temperatures and vibration to ensure reliable performance in demanding automotive environments.

Aerospace & Defense: FPCs are critical for aerospace applications, where weight reduction and space optimization directly impact fuel efficiency and payload capacity. They power avionics systems, satellite components, and military communication devices, withstanding radiation, extreme temperature swings, and mechanical stress in outer space or combat environments.

Industrial IoT & Automation: FPC fabrication supports the growth of smart factories by enabling compact, durable sensors and controllers for industrial robots, conveyor systems, and predictive maintenance tools. FPCs operate reliably in harsh industrial conditions—including dust, humidity, and temperature fluctuations—ensuring seamless connectivity and data collection for IoT ecosystems.

As the electronics industry prioritizes sustainability, FPC Fabrication is evolving to minimize environmental impact:

Material Efficiency: FPC fabrication uses thinner substrates and conductive layers, reducing material waste compared to rigid PCBs. Advanced manufacturing processes optimize material usage, lowering resource consumption and carbon footprint.

Energy Savings: The lightweight nature of FPCs reduces the energy required to power and transport devices—especially critical for battery-operated products like wearables and EVs. FPCs also support energy-efficient designs by minimizing signal loss and optimizing power distribution.

Circular Design Compatibility: Many FPC materials are recyclable or reusable, aligning with circular economy principles. Manufacturers are increasingly adopting lead-free, low-VOC processes to reduce environmental harm, ensuring FPC fabrication complies with global sustainability standards.

FPC Fabrication is poised for continued evolution, driven by emerging technologies and market demands:

Advanced Material Integration: The adoption of next-generation materials—such as flexible ceramics and carbon nanotubes—will enhance FPC performance, enabling higher temperature resistance, faster signal transmission, and improved durability.

Hybrid Rigid-Flex Designs: Combining flexible and rigid sections in a single circuit will become more prevalent, offering the best of both worlds for complex applications like medical implants and aerospace systems.

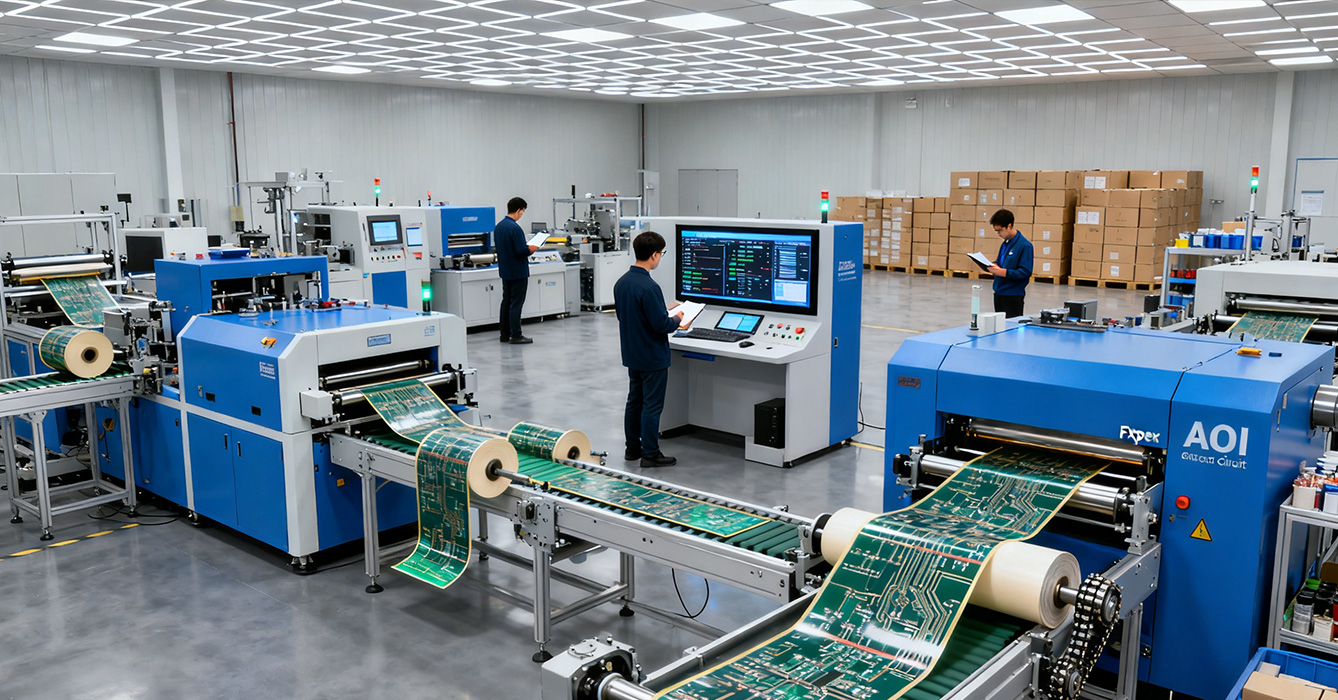

AI-Driven Manufacturing: Artificial intelligence and machine learning will optimize FPC fabrication workflows, from design validation to quality control, reducing lead times and improving defect detection.

Miniaturization & High-Density Circuits: As devices become smaller and more powerful, FPC fabrication will support even finer circuit traces and denser component placement, enabling higher performance in compact form factors.

In conclusion, FPC Fabrication is a cornerstone of modern electronics innovation, delivering flexibility, efficiency, and reliability across industries. From consumer gadgets to life-saving medical devices and cutting-edge aerospace systems, FPCs enable designs that were once impossible with rigid PCBs. As sustainability and miniaturization become increasingly critical, FPC Fabrication will continue to evolve, driving the next generation of flexible, connected, and sustainable electronics. For engineers and manufacturers, embracing FPC fabrication is not just a technical choice—it’s a strategic investment in creating products that meet the demands of a rapidly changing world.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB