-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 10. 2025, 13:42:49

In the globalized electronics industry, flexible printed circuits (FPCs) serve as core components across consumer electronics, industrial automation, new energy vehicles, and medical devices. A professional FPC manufacturer stands out through robust global compliance capabilities and seamless cross-industry technology integration, enabling it to navigate diverse market regulations and meet the varied technical demands of different sectors. Unlike regional or niche FPC suppliers, leading FPC manufacturers prioritize global regulatory alignment and cross-domain technical innovation, providing reliable, market-accessible solutions for clients worldwide. For electronics brands pursuing global market expansion and product diversification, partnering with an FPC manufacturer with strong compliance and integration capabilities is a strategic necessity.

The ability to comply with global regulatory standards is a key competitive advantage for FPC manufacturers, ensuring their products can enter major markets smoothly:

- Multi-Region Regulatory Adaptation: Top FPC manufacturers proactively align with regional regulations, including the European Union’s RoHS/REACH, North America’s UL/CSA, Asia’s CCC/KC, and automotive-specific IATF 16949. They establish dedicated compliance teams to monitor regulatory updates, conduct pre-compliance testing, and ensure raw materials, production processes, and final products meet the latest requirements. For example, for medical FPCs, they strictly comply with ISO 13485 to support clients’ medical device market access.

- Environmental & Sustainability Compliance: As global sustainability demands rise, FPC manufacturers integrate eco-friendly practices into their operations. They adopt low-VOC (volatile organic compound) production processes, use recyclable or bio-based materials, and implement carbon footprint tracking systems. These measures not only meet environmental regulations but also align with the sustainability goals of global electronics brands, enhancing long-term cooperation potential.

- Compliance Documentation & Traceability: To streamline clients’ market certification processes, manufacturers provide comprehensive compliance documentation, including material safety data sheets (MSDS), test reports, and certification certificates. They also establish full-lifecycle traceability systems, tracking raw material sources, production batches, and testing records, which is critical for regulatory audits and quality accountability.

Leading FPC manufacturers excel in integrating technologies across industries, tailoring solutions to the unique technical needs of different sectors:

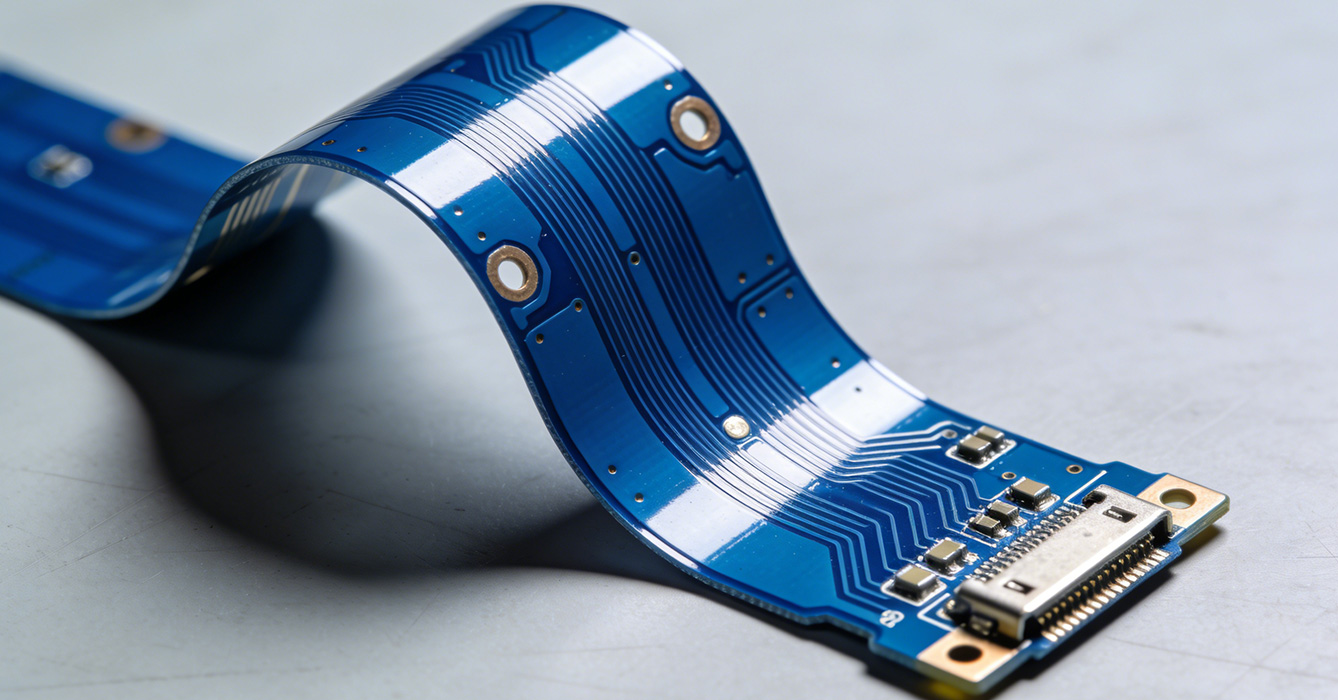

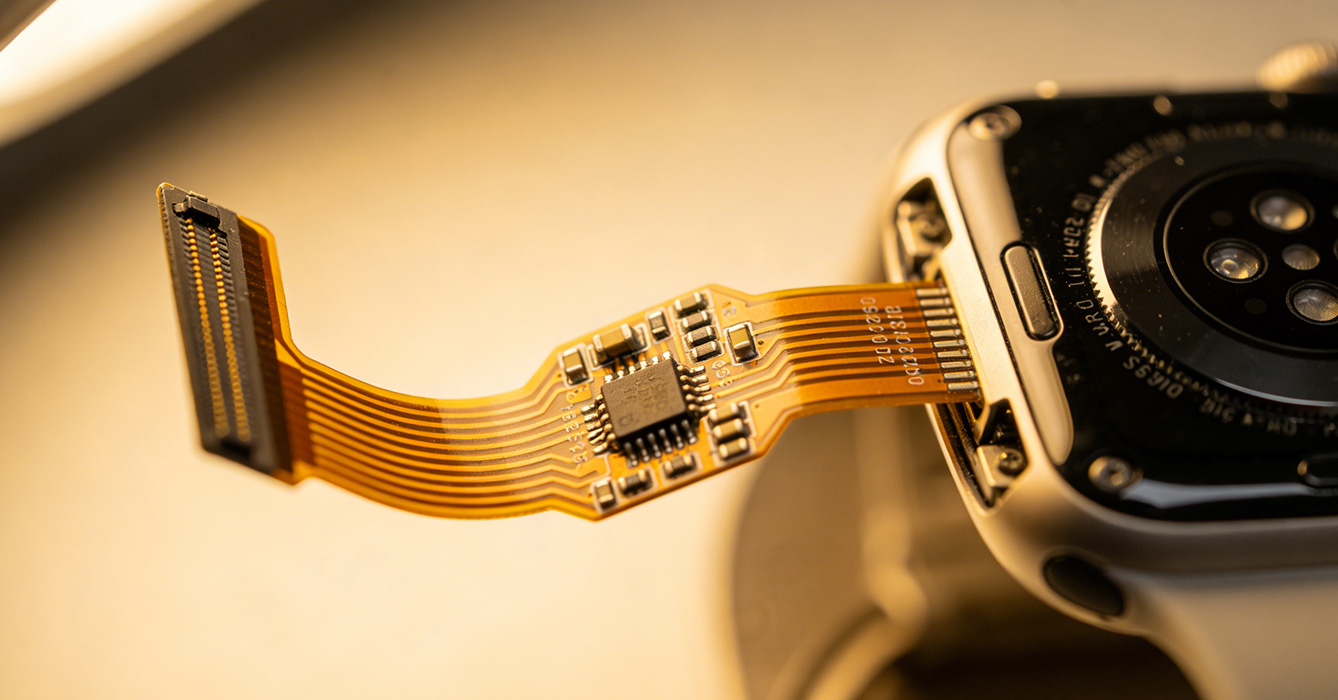

- Consumer Electronics & Smart Devices: For smartphones, wearables, and smart home devices, manufacturers integrate ultra-thin, low-power FPC designs with high-frequency signal transmission capabilities. They combine flexible substrate technology with miniaturized component integration, supporting slim form factors and advanced functions such as wireless charging and multi-sensor connectivity.

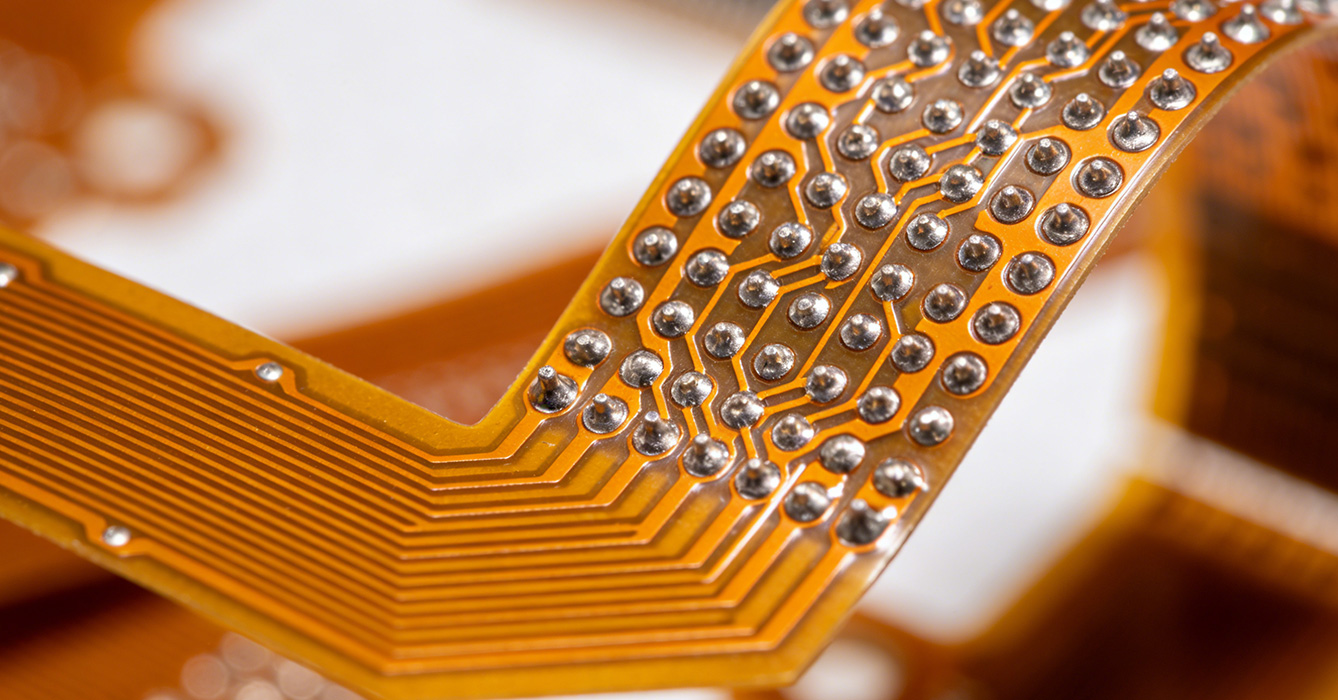

- Industrial Automation & IoT: Industrial FPCs require high reliability in harsh environments. Manufacturers integrate ruggedized materials, EMI shielding, and high-temperature-resistant components into FPC designs, ensuring stable performance under dust, vibration, and extreme temperature conditions. They also support industrial IoT integration by optimizing FPCs for sensor signal collection and data transmission.

- New Energy Vehicles (NEV): NEV applications (battery management systems, in-vehicle electronics) demand FPCs with high current-carrying capacity and thermal stability. Manufacturers integrate high-thermal-conductivity substrates, flame-retardant materials, and vibration-resistant structures, complying with strict automotive safety standards. They also optimize FPC layouts to support the high-voltage, high-current requirements of NEV power systems.

- Medical Devices: Medical FPCs require biocompatibility, precision, and sterility. Manufacturers use medical-grade materials, implement sealed designs to prevent contamination, and integrate high-precision circuit patterns for accurate signal transmission. These FPCs support critical medical applications such as patient monitors, diagnostic equipment, and wearable health devices.

Top FPC manufacturers build global service ecosystems to support clients’ international operations, enhancing collaboration efficiency:

- Localized Production & Supply Chain: To reduce lead times and logistics costs, manufacturers establish production bases and supply chain networks in key regions (e.g., Asia, Europe, North America). Localized production enables rapid response to regional market demands and compliance with local manufacturing regulations, ensuring timely delivery of FPC solutions.

- Multilingual Technical Support & Co-Development: They provide 24/7 multilingual technical support, assisting clients with design optimization, compliance consulting, and troubleshooting. Manufacturers also engage in early-stage co-development with clients, leveraging their cross-industry expertise to provide DFM (Design for Manufacturability) insights, accelerating product development cycles.

- Flexible Order & Customization Services: To meet the diverse needs of global clients, manufacturers offer flexible order options, from small-batch prototypes to high-volume production. They provide customized FPC solutions tailored to clients’ specific application scenarios, balancing technical performance, cost efficiency, and compliance requirements.

Forward-looking FPC manufacturers invest in R&D to adapt to emerging industry trends, ensuring long-term competitiveness:

- Advanced Semiconductor & 6G Integration: They develop FPCs compatible with advanced semiconductor packaging technologies (e.g., chip-on-flex) and optimize designs for 6G high-frequency signal transmission, supporting the next generation of communication devices.

- Flexible Electronics & Wearable Technology: Manufacturers explore stretchable FPC materials and structures, enabling FPCs to adapt to dynamic deformation in wearable devices, smart clothing, and flexible displays.

- Green Energy & Circular Economy: They continue to advance sustainable FPC technologies, such as fully recyclable FPCs and low-energy-consumption production processes, supporting the global transition to a circular economy.

In conclusion, an FPC manufacturer’s global compliance capabilities and cross-industry technology integration are key enablers of its success in the global electronics market. By navigating complex regulatory landscapes, tailoring solutions to diverse sectors, and building a customer-centric global service ecosystem, these manufacturers empower clients to expand globally and innovate across industries. As emerging technologies and sustainability demands reshape the electronics industry, the strategic value of partnering with an FPC manufacturer with strong compliance and integration capabilities will only grow, making it a critical asset for brands aiming to thrive in the global marketplace.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB