-

- PCB TYPE

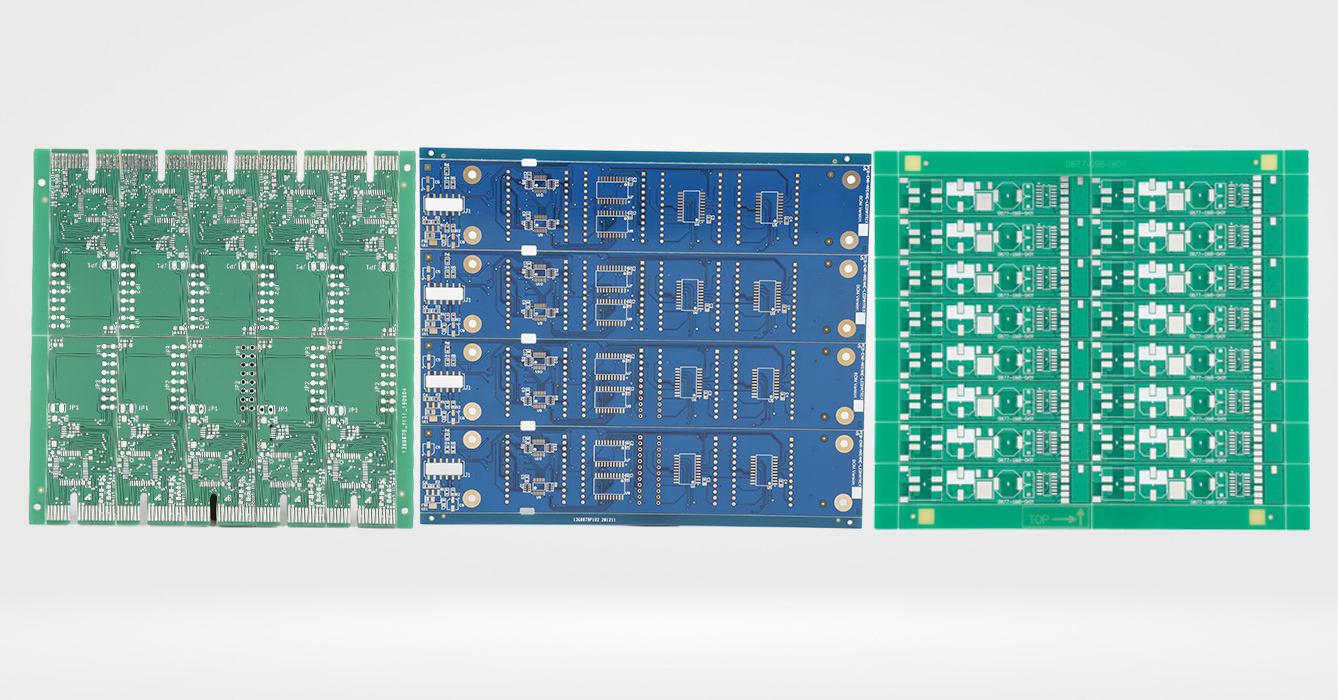

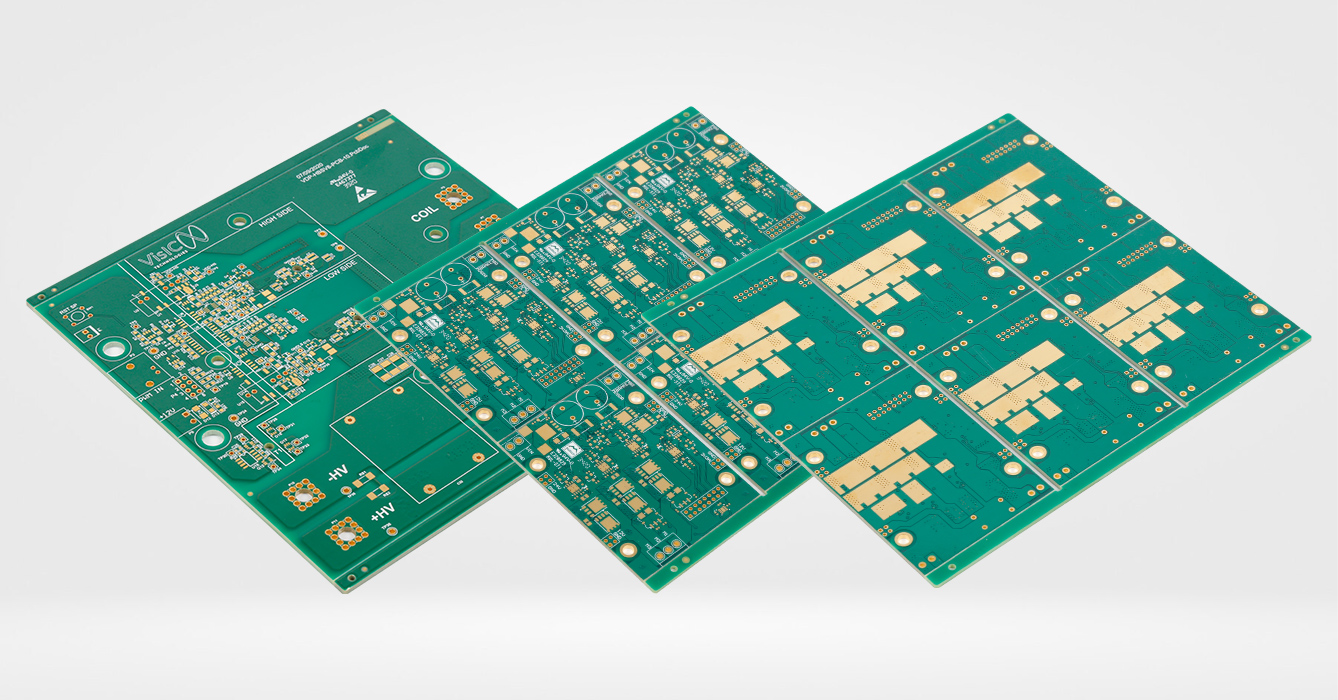

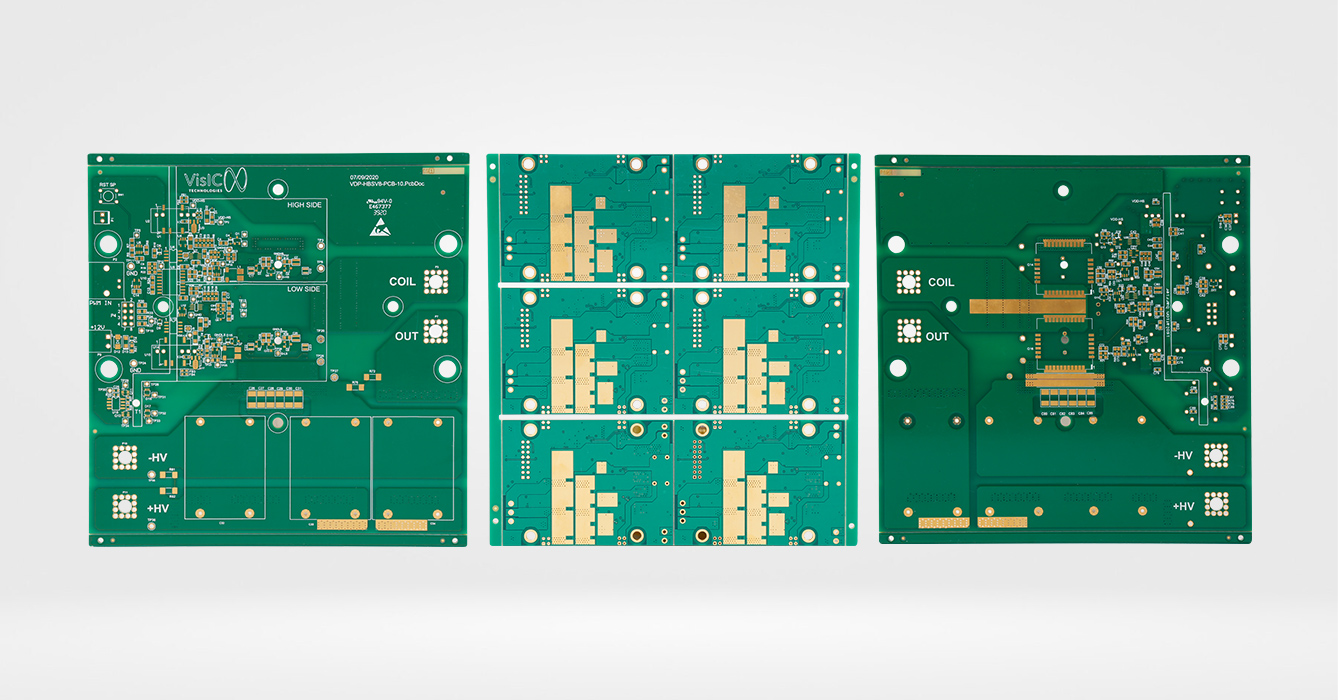

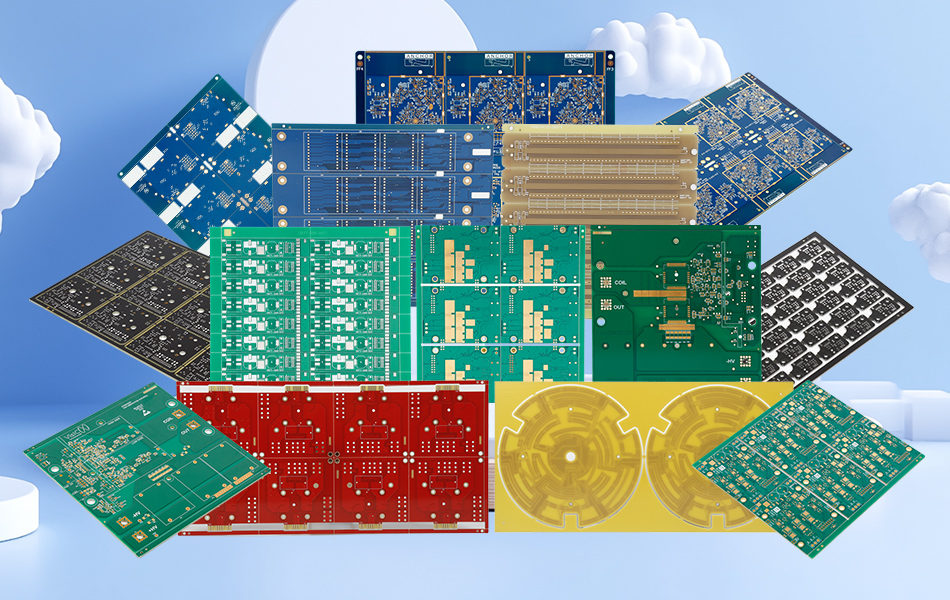

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 11. 2025, 15:44:56

In the realm of electronics manufacturing, the FR4 PCB Material Spec Sheet PDF serves as an indispensable document, bridging the gap between material suppliers, designers, and manufacturers. This digital or printable resource encapsulates essential information about FR4 PCB materials, guiding decision-making throughout the product development lifecycle. Unlike generic product descriptions, an FR4 PCB Material Spec Sheet PDF is a detailed, standardized document that outlines a material’s properties, compliance, and performance characteristics—critical for ensuring that the chosen FR4 variant aligns with a project’s requirements. This article explores the role, structure, and significance of these spec sheets, highlighting how they facilitate collaboration, ensure quality, and streamline the production of FR4-based PCBs.

An FR4 PCB Material Spec Sheet PDF is designed to provide clear, concise, and standardized information about a specific FR4 material variant. Its primary goals are to:

Inform Selection: Help engineers and designers choose the right FR4 material by detailing its key attributes, such as thermal resistance, flame retardancy, and electrical performance, ensuring it matches the application’s needs.

Ensure Compliance: Verify that the material meets industry standards, regulatory requirements, and safety certifications, which is crucial for market access and liability mitigation.

Guide Manufacturing: Provide manufacturers with critical data to optimize processing parameters, such as lamination temperatures, drilling techniques, and surface treatments, reducing errors and waste.

Facilitate Communication: Serve as a common reference point for suppliers, designers, and manufacturers, minimizing misunderstandings and ensuring everyone works from the same set of material properties.

By consolidating this information in a portable, easily shareable PDF format, these spec sheets become a vital tool in the electronics supply chain, supporting efficiency and accuracy at every stage.

While the exact structure may vary by supplier, a comprehensive FR4 PCB Material Spec Sheet PDF typically includes several core sections, each addressing a critical aspect of the material:

This section introduces the FR4 variant, including its product name, part number, and a brief description of its intended use. It may also note whether it is a standard, high-temperature, halogen-free, or low-dielectric variant, helping users quickly determine if it aligns with their needs.

Compliance and Certifications

A critical section for regulatory and safety purposes, this outlines the material’s adherence to industry standards and certifications. Examples include UL flame resistance ratings, IPC specifications, RoHS or REACH compliance, and automotive standards like IATF 16949. This ensures the material meets legal and safety requirements for specific markets or applications.

While avoiding specific percentages, this section describes the key components of the FR4 material, such as the type of epoxy resin (e.g., bisphenol-A, novolac), glass fiber reinforcement (e.g., E-glass, S-glass), and flame retardant type (e.g., halogenated, phosphorus-based). This helps users understand the material’s core structure and how it might perform in different conditions.

This section details the material’s functional properties, focusing on qualitative descriptions rather than precise metrics. It may include information on:

Thermal Behavior: How the material responds to temperature changes, including its ability to resist softening or warping under heat.

Electrical Properties: General notes on insulation capabilities, signal integrity, and resistance to interference.

Mechanical Strength: Descriptions of flexibility, rigidity, and resistance to impact or vibration.

Environmental Resistance: Information on how the material holds up to moisture, chemicals, or UV exposure.

Practical advice for manufacturers, this section offers recommendations for handling the material during lamination, drilling, etching, and finishing. It may include notes on optimal curing conditions, tooling considerations, and surface preparation to ensure consistent results.

Guidelines for storing the material to maintain its properties, such as temperature and humidity ranges, shelf life, and precautions to prevent damage during transport or storage.

Links or references to related documents, such as safety data sheets (SDS), technical white papers, or contact information for supplier support, enabling users to seek further details if needed.

Together, these sections create a holistic view of the FR4 material, empowering users to make informed decisions.

For engineers, designers, and manufacturers, FR4 PCB Material Spec Sheet PDFs are more than just reference documents—they are essential for success in several ways:

These spec sheets help engineers select materials that align with their design goals. By reviewing performance characteristics and compliance information, they can ensure the chosen FR4 variant will withstand the intended operating environment, whether it’s a high-heat industrial setting or a moisture-prone consumer device. This reduces the risk of redesigns or failures later in the process.

Manufacturers rely on the processing guidelines in spec sheets to optimize their production lines. Knowing how a specific FR4 variant behaves during lamination or drilling allows them to adjust equipment settings, reducing waste and ensuring consistent quality. Compliance information also helps manufacturers verify that the material meets the standards required by their clients or target markets.

Procurement professionals use spec sheets to compare different FR4 materials and suppliers, ensuring they source products that meet both technical and regulatory requirements. Quality teams reference these documents during inspections to confirm that received materials match the specifications, maintaining consistency across production runs.

Spec sheets help suppliers communicate transparently about their products, building trust with clients. By providing clear, standardized information, they reduce the need for back-and-forth inquiries and demonstrate their commitment to quality and compliance.

In essence, FR4 PCB Material Spec Sheet PDFs act as a common language that unites all stakeholders in the electronics manufacturing process.

To maximize the value of an FR4 PCB Material Spec Sheet PDF, professionals should follow these best practices:

Start by defining the needs of your application—such as operating temperature range, environmental conditions, and regulatory requirements. Then, cross-reference these needs with the spec sheet’s compliance and performance sections to identify the most suitable FR4 variant.

Share the spec sheet with design, manufacturing, and procurement teams to ensure everyone agrees on the material’s suitability. This collaborative review helps catch potential issues early, such as a mismatch between the material’s processing needs and the manufacturer’s capabilities.

Don’t assume a material meets all standards based on its name alone. Use the spec sheet to confirm compliance with relevant regulations (e.g., RoHS for European markets) and industry standards (e.g., IPC for PCB materials). This is especially critical for products sold in multiple regions.

If issues arise during manufacturing or testing—such as warping, poor adhesion, or signal loss—refer back to the spec sheet. The performance characteristics and processing guidelines may offer insights into the root cause, such as improper curing temperatures or incompatible handling.

Material formulations can change over time, so ensure you are using the latest version of the spec sheet. Suppliers often update PDFs to reflect improvements, new certifications, or revised processing guidelines, and relying on outdated information can lead to errors.

By integrating these practices, professionals can leverage spec sheets to streamline processes, reduce risks, and ensure the success of their FR4-based projects.

While invaluable, FR4 PCB Material Spec Sheet PDFs can present challenges that users must navigate:

Different suppliers may structure their spec sheets differently, making it difficult to compare materials side by side. To address this, create a standardized checklist of key criteria (e.g., compliance, thermal behavior) and use it to evaluate each spec sheet, ensuring apples-to-apples comparisons.

Spec sheets often contain industry-specific terms that may be unfamiliar to newer professionals. Take the time to learn key terms (e.g., “Tg,” “flame retardancy class”) or consult with experienced colleagues to avoid misinterpretation.

Some spec sheets may lack information relevant to your application, such as performance in extreme humidity. In such cases, reach out to the supplier for clarification—reputable suppliers will provide additional data to support your decision-making.

As mentioned, using old spec sheets can lead to mistakes. Set up alerts with suppliers to receive notifications when spec sheets are updated, or regularly check their websites for the latest versions.

By proactively addressing these challenges, users can ensure they derive maximum value from FR4 PCB Material Spec Sheet PDFs.

As the electronics industry evolves, FR4 PCB Material Spec Sheet PDFs are likely to adapt to new needs and technologies:

Spec sheets may become more interactive, with links to 3D models, video tutorials on processing, or dynamic tables that allow users to filter information by application (e.g., “automotive” or “medical”). This would make it easier to find relevant details quickly.

Given the growing emphasis on eco-friendly manufacturing, future spec sheets may include more detailed information on a material’s environmental impact, such as recyclability, carbon footprint, or use of bio-based components.

Industry bodies may work to standardize spec sheet formats, reducing inconsistency and making cross-supplier comparisons simpler. This would streamline the material selection process and reduce errors.

With more professionals working remotely, spec sheets may be optimized for mobile devices, allowing easy access on the factory floor or during client meetings.

These developments would enhance the utility of FR4 PCB Material Spec Sheet PDFs, making them even more integral to electronics manufacturing.

The FR4 PCB Material Spec Sheet PDF is a cornerstone of efficient, high-quality electronics manufacturing, providing critical information that guides material selection, ensures compliance, and supports collaboration across the supply chain. By understanding its components, leveraging its insights, and navigating its challenges, professionals can harness the power of these documents to drive success in their FR4-based projects. As the industry advances, spec sheets will continue to evolve, reflecting new technologies, standards, and sustainability goals—solidifying their role as essential tools for anyone working with FR4 PCBs. Whether you’re a design engineer, manufacturer, or procurement specialist, mastering the use of FR4 PCB Material Spec Sheet PDFs is key to delivering reliable, compliant, and high-performance electronic products.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB