-

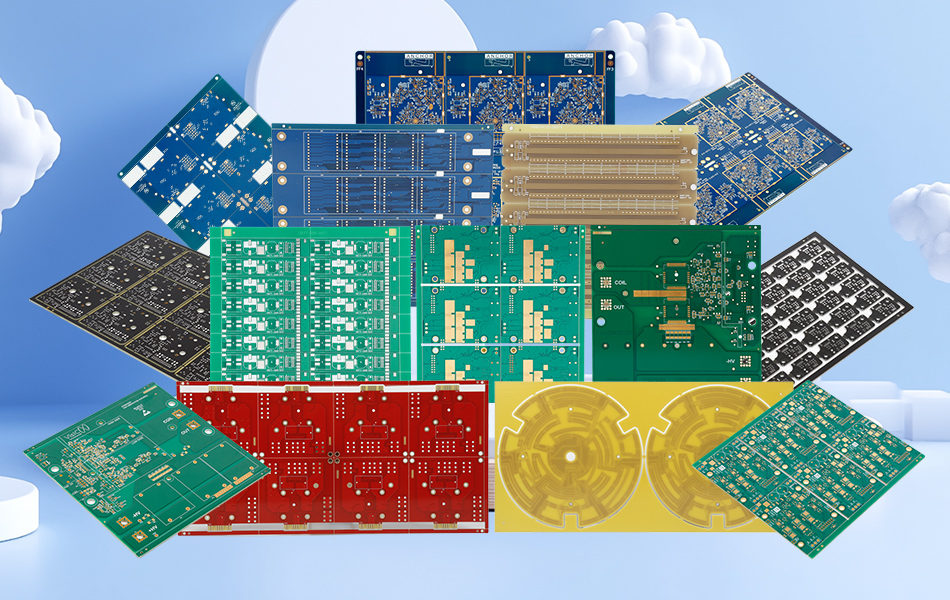

- PCB TYPE

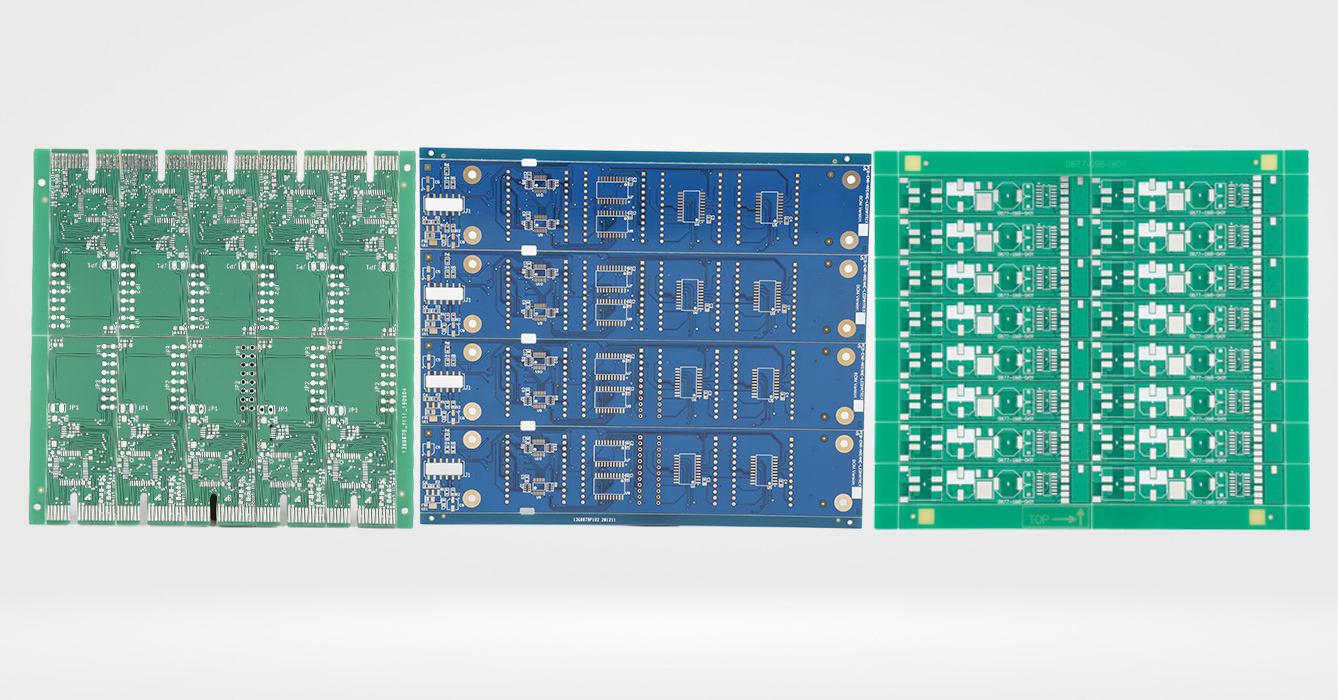

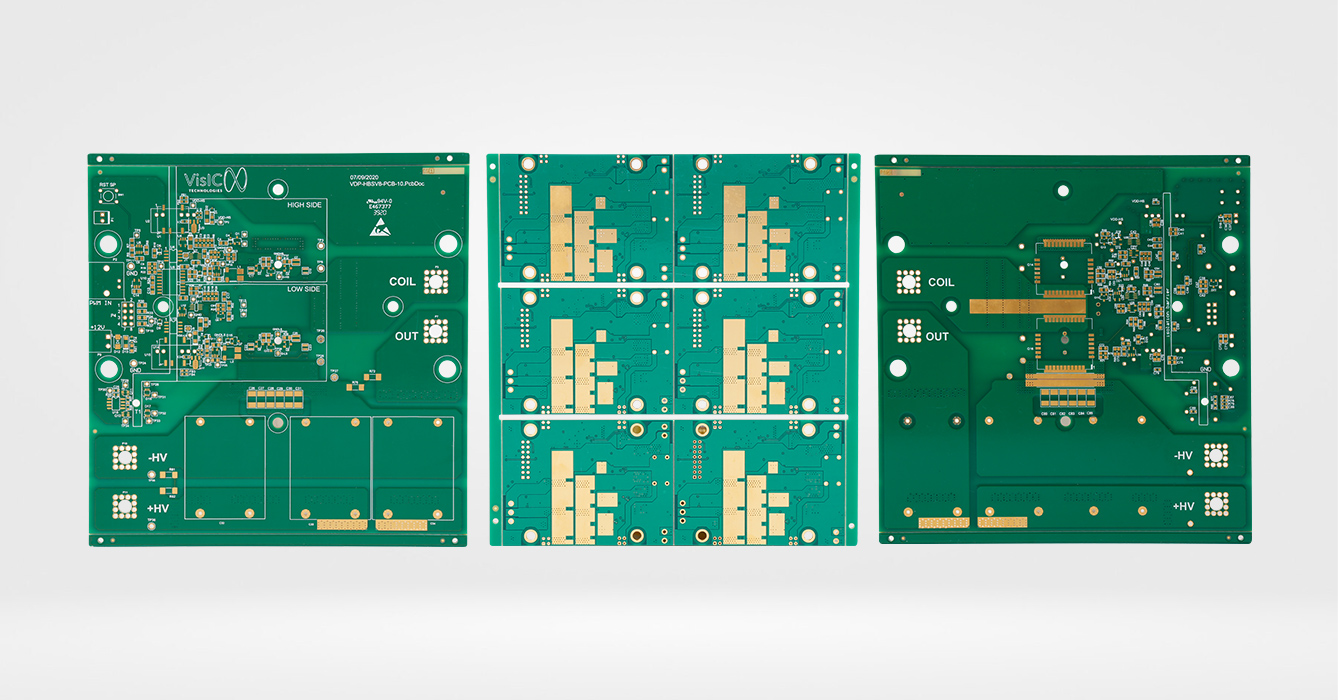

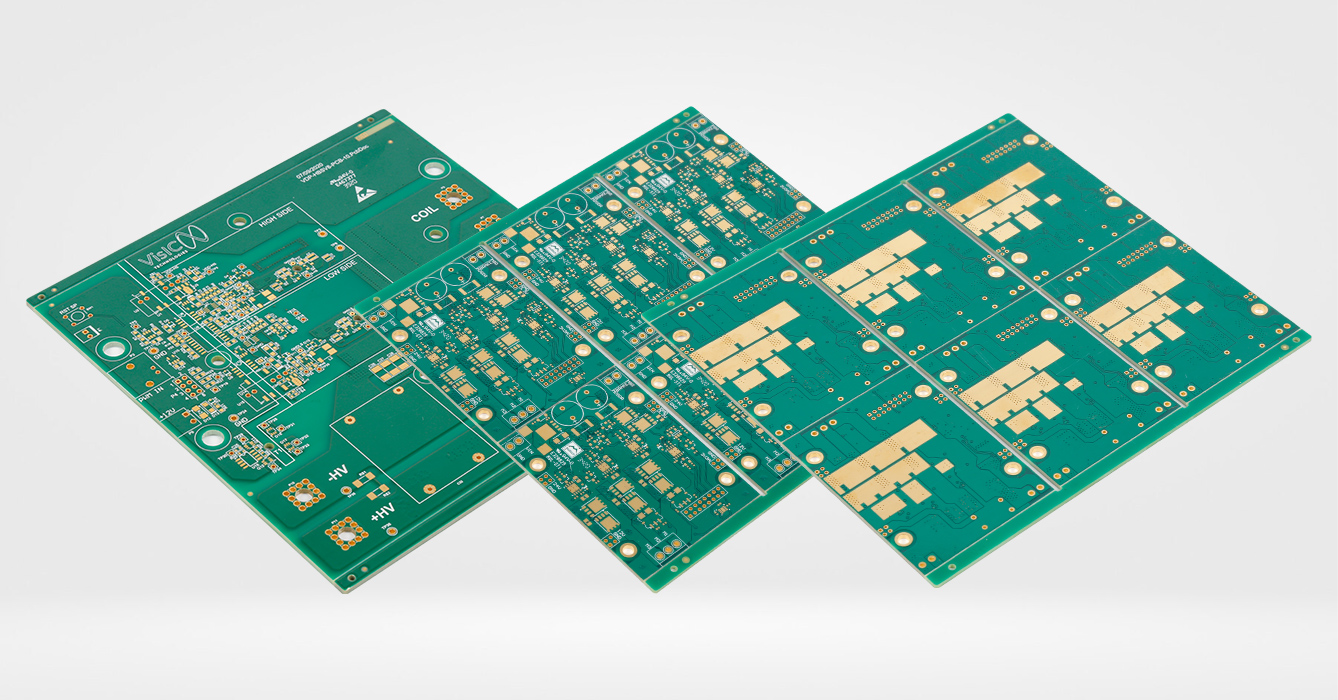

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 11. 2025, 16:15:58

The FR4 PCB Material Specification serves as the backbone of reliability in electronics manufacturing, establishing standardized guidelines for the properties, performance, and compliance of FR4-based printed circuit boards. As the most widely used PCB material globally, FR4’s versatility demands clear specifications to ensure consistency across manufacturers, applications, and industries. These specifications are not static documents but dynamic frameworks that adapt to technological advancements, regulatory changes, and evolving market needs. This article explores the structure, purpose, and practical implications of FR4 PCB material specifications, highlighting how they guide material selection, manufacturing processes, and quality assurance—ultimately ensuring that FR4 PCBs meet the diverse demands of modern electronics.

At its core, an FR4 PCB Material Specification is designed to address three critical needs in the electronics supply chain:

Standardization: With countless manufacturers producing FR4 variants, specifications ensure that materials labeled as "FR4" meet baseline requirements for flame resistance, mechanical strength, and electrical insulation. This allows designers and engineers to select materials with confidence, knowing that performance claims are consistent across suppliers.

Risk Mitigation: By defining compliance with safety and environmental regulations (such as RoHS, UL, and IPC standards), specifications reduce the risk of using non-compliant materials, which could lead to product recalls, legal penalties, or safety hazards.

Performance Alignment: Specifications bridge the gap between material capabilities and application requirements. They help engineers match FR4 variants—whether standard, high-temperature, halogen-free, or low-dielectric—to the specific needs of a project, ensuring optimal performance without over-engineering.

In essence, FR4 PCB material specifications act as a common language, enabling collaboration between material suppliers, PCB manufacturers, and end-users while upholding quality and reliability.

While specific details vary by application and industry, a comprehensive FR4 PCB material specification typically includes the following key sections:

This section defines the FR4 variant, categorizing it by its primary attributes—such as thermal rating (e.g., standard Tg vs. high Tg), flame retardant type (halogenated vs. halogen-free), or electrical properties (low-dielectric vs. standard). It may also include product codes, trade names, and intended use cases to avoid ambiguity.

A cornerstone of any specification, this outlines the material’s adherence to global standards and regulations. This includes:

Flame retardancy certifications (e.g., UL94 V-0, IEC 60695) to ensure fire safety.

Environmental compliance (e.g., RoHS, REACH) restricting hazardous substances.

Industry-specific standards (e.g., IPC-4101 for PCB laminates, automotive IATF 16949) to meet sector-specific needs.

Rather than specifying exact ratios, this section describes the permissible components of the FR4 laminate, including:

Resin type: Epoxy formulations (e.g., bisphenol-A, novolac) tailored to the material’s intended use.

Reinforcement: Glass fiber type (e.g., E-glass, S-glass) and weave pattern, which influence mechanical strength and dimensional stability.

Additives: Flame retardants, fillers, or modifiers used to enhance specific properties (e.g., thermal conductivity, UV resistance).

This section outlines qualitative requirements for the material’s functional behavior, focusing on:

Thermal performance: Resistance to softening, warping, or delamination under specified temperature ranges.

Mechanical properties: Rigidity, flexibility, and resistance to impact or vibration, ensuring durability during handling and operation.

Electrical characteristics: Insulation capability, signal integrity, and resistance to interference, critical for maintaining circuit functionality.

Environmental resistance: Performance under exposure to moisture, chemicals, or UV radiation, relevant for outdoor or harsh-environment applications.

To ensure consistent production, specifications include recommendations for:

Lamination conditions: Curing temperatures, pressure, and dwell times to achieve optimal resin cross-linking.

Machining processes: Drilling, routing, and etching techniques that preserve material integrity.

Finishing steps: Compatibility with solder masks, adhesives, and surface treatments to ensure reliable component bonding.

This section defines procedures to verify compliance, such as:

Sampling methods: How to select representative samples for testing.

Test standards: Protocols for evaluating properties (e.g., thermal cycling, peel strength) using industry-recognized methods.

Acceptance criteria: Thresholds for passing or failing tests, ensuring only cases materials enter the supply chain.

FR4 specifications are not one-size-fits-all; they are tailored to the unique demands of different industries and applications:

Consumer Electronics: Specifications prioritize cost-effectiveness and basic performance, with a focus on standard Tg, halogen compliance, and ease of processing. They often reference RoHS and UL standards to meet global market requirements.

Automotive Electronics: Specifications emphasize thermal stability (for underhood or cabin environments), vibration resistance, and long-term reliability. They align with IATF 16949 and automotive flame retardancy standards (e.g., ISO 3795).

Industrial Equipment: Specifications focus on durability in harsh conditions, including resistance to chemicals, moisture, and wide temperature fluctuations. They may reference IEC standards for industrial machinery.

Medical Devices: Specifications prioritize biocompatibility, low toxicity (often requiring halogen-free formulations), and reliability in controlled environments. Compliance with ISO 13485 and FDA guidelines is common.

Aerospace and Defense: Specifications demand extreme performance, including high-Tg resins, enhanced mechanical strength, and resistance to radiation. They align with MIL-STD standards for mission-critical applications.

These variations ensure that FR4 materials are fit for purpose, balancing performance with practicality across diverse use cases.

For engineers and procurement professionals, FR4 PCB material specifications are invaluable tools for making informed decisions:

Matching Material to Application: By cross-referencing an application’s requirements (e.g., operating temperature, regulatory needs) with a specification’s performance criteria, engineers can identify the most suitable FR4 variant. For example, a high-power LED driver would require a specification with enhanced thermal performance, while a low-cost toy PCB could use a standard specification.

Evaluating Supplier Capabilities: Specifications enable objective comparisons of supplier offerings, ensuring that materials meet consistent quality standards regardless of origin. This is particularly important in global supply chains with multiple vendors.

Mitigating Design Risks: By adhering to a recognized specification, engineers reduce the risk of material failure, which could lead to redesigns, delays, or safety issues. Specifications provide a benchmark for performance, ensuring the material can withstand the application’s intended conditions.

Facilitating Regulatory Compliance: For products sold in multiple regions, specifications that reference global standards (e.g., RoHS, UL) simplify compliance, avoiding the need to navigate conflicting local regulations.

While specifications are critical, their implementation is not without challenges:

Interpretation Variability: Different manufacturers may interpret vague language in specifications differently, leading to inconsistent material quality. This is mitigated by using industry-recognized standards (e.g., IPC) that define terms precisely.

Evolving Requirements: As technology advances, specifications must be updated to reflect new needs (e.g., higher signal speeds, lower environmental impact). Stakeholders must stay current with revisions to avoid using outdated guidelines.

Balancing Flexibility and Rigidity: Overly prescriptive specifications can stifle innovation, while overly vague ones may compromise quality. The best specifications strike a balance, defining essential requirements while allowing room for material advancements.

Cost vs. Performance: Tight specifications for high-performance applications often increase material costs. Engineers must weigh the benefits of enhanced performance against budget constraints, using specifications to identify cost-effective solutions that meet minimum requirements.

As electronics continue to evolve, FR4 specifications are adapting to new trends:

Sustainability Integration: Future specifications will likely include criteria for recyclability, use of bio-based resins, and carbon footprint, aligning with global efforts to reduce environmental impact.

Multi-Functional Materials: Specifications will increasingly address FR4 variants with combined properties (e.g., high-Tg + halogen-free + low-dielectric), reflecting the demand for materials that meet multiple needs in complex devices like electric vehicles.

Digitalization: Specifications may shift from static documents to dynamic digital resources, with embedded links to test data, supplier certifications, and real-time updates, improving accessibility and accuracy.

Standardization Harmonization: Efforts to align regional standards (e.g., EU vs. Asian) will simplify global supply chains, reducing the need for multiple specifications for the same material.

These developments will ensure that FR4 PCB material specifications remain relevant, guiding the industry toward more sustainable, reliable, and innovative electronics.

The FR4 PCB Material Specification is an essential framework that ensures consistency, reliability, and compliance in the production and use of FR4 laminates. By defining material composition, performance criteria, and quality standards, it enables collaboration across the electronics supply chain, from material suppliers to end-users. As technology advances and applications become more demanding, specifications will continue to evolve, reflecting new needs for sustainability, performance, and safety. For engineers, manufacturers, and procurement professionals, understanding and leveraging these specifications is key to selecting the right FR4 material, reducing risks, and delivering high-quality electronic products. In a world of diverse applications and global supply chains, FR4 PCB material specifications are the foundation of trust in one of the most critical materials in modern electronics.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB