-

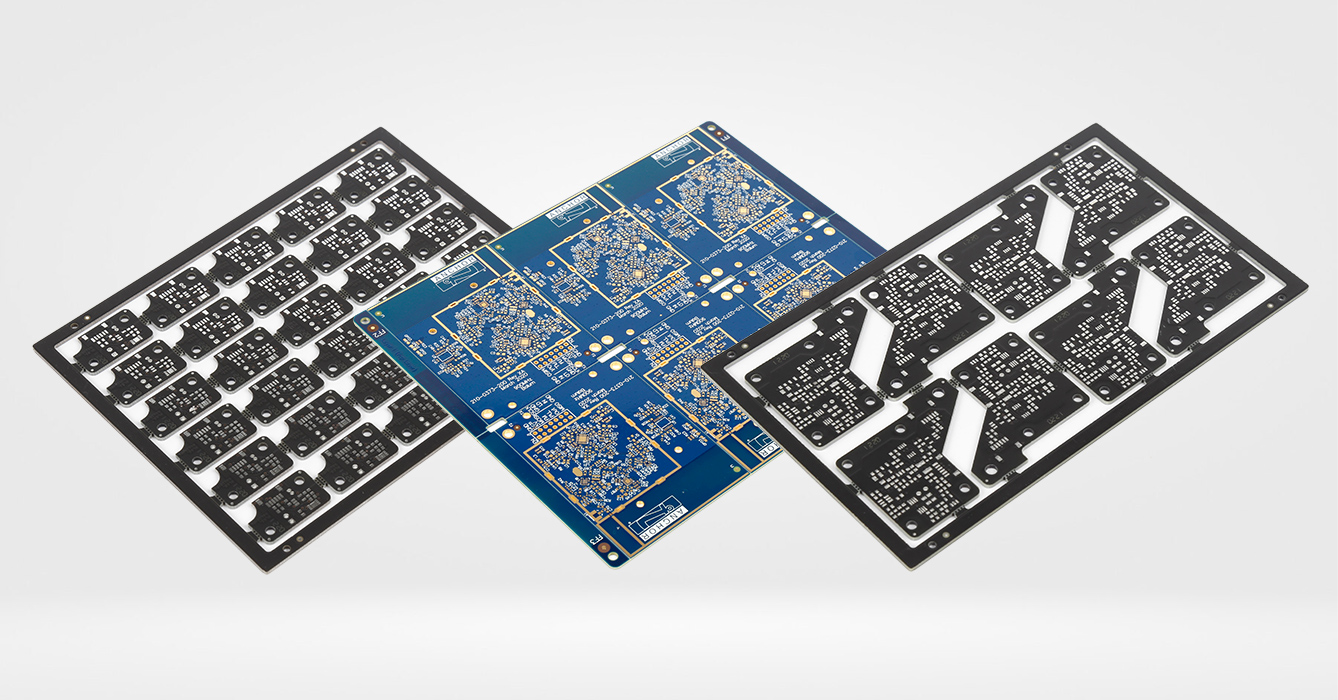

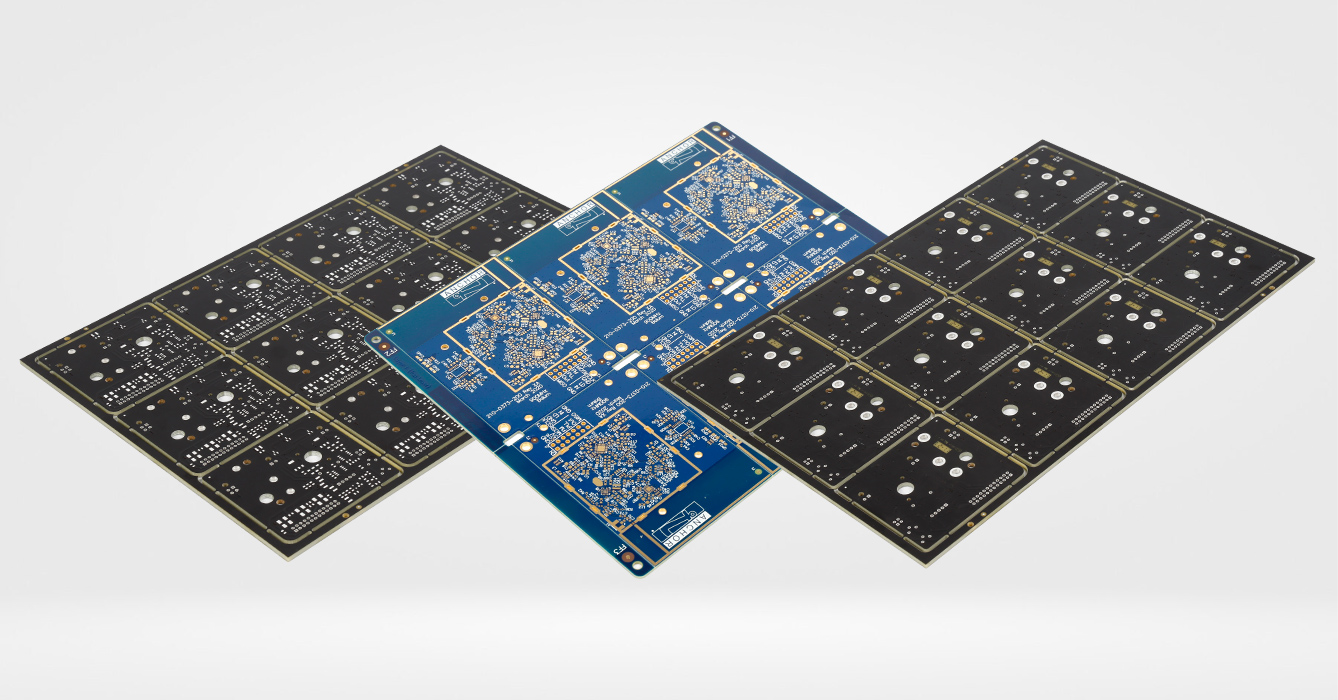

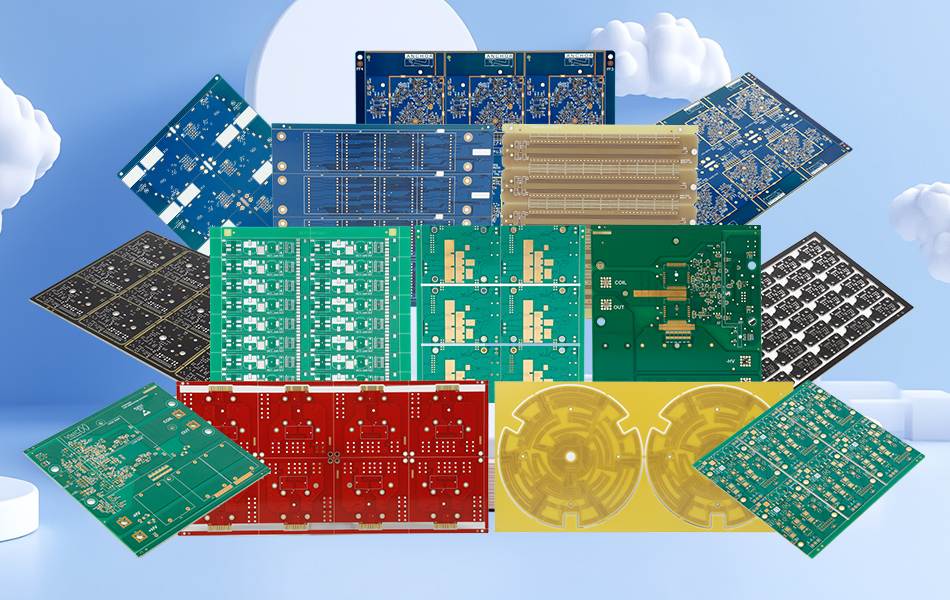

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 08. 2025, 17:09:37

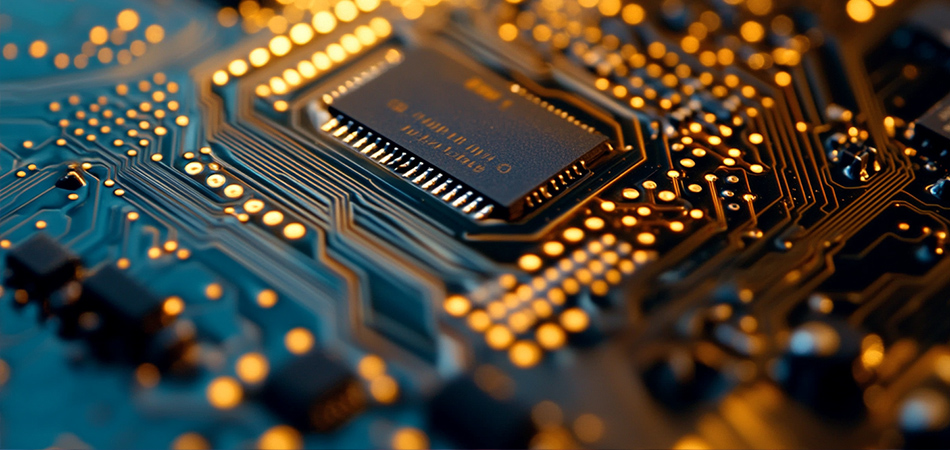

FR4 PCB remains the cornerstone of modern electronics, a material whose adaptability has allowed it to evolve alongside the industry’s most demanding challenges. From the earliest integrated circuits to today’s 5G infrastructure and IoT ecosystems, FR4 has proven its worth as a cost-effective, reliable substrate for printed circuit boards. Its unique combination of mechanical strength, electrical insulation, and flame resistance—coupled with ongoing material innovations—ensures it remains indispensable. This article explores the latest developments in FR4 PCB technology, from advanced formulations to novel manufacturing techniques, while examining its expanding role in emerging applications. By focusing on its evolving properties, sustainability gains, and integration with cutting-edge electronics, we highlight why FR4 continues to dominate the PCB market and what the future holds for this versatile material.

At its essence, FR4 PCB is a composite material designed to balance multiple performance metrics. Its structure consists of three key components, each contributing to its overall functionality:

Epoxy Resin Matrix: The binding agent that holds the laminate together, epoxy resin provides electrical insulation (volume resistivity ≥10¹⁴ Ω·cm) and chemical resistance. Modern FR4 uses tailored epoxy formulations—from standard bisphenol-A to high-performance novolac resins—to meet specific thermal and mechanical requirements. For example, bisphenol-F epoxies reduce water absorption by 20–30% compared to traditional bisphenol-A, enhancing reliability in humid environments.

Glass Fiber Reinforcement: Woven glass fibers (typically E-glass) add mechanical strength, with tensile strength exceeding 3,400 MPa. The fiber weave pattern—such as 1080 (fine) or 7628 (heavy)—dictates the laminate’s thickness (0.1–6.4 mm) and rigidity. Advanced variants use S-glass, which offers 30% higher strength than E-glass, making them suitable for aerospace and military applications where vibration resistance is critical.

Flame Retardant Additives: To achieve UL94 V-0 certification, FR4 incorporates flame retardants. Traditional brominated compounds are increasingly replaced by phosphorus-based alternatives, which reduce environmental impact while maintaining fire resistance—a shift driven by regulations like EU RoHS 2.0.

This composite structure results in a material that supports complex circuitry while withstanding the physical and thermal stresses of real-world operation.

FR4 is no longer a one-size-fits-all solution. Manufacturers now offer specialized variants to address specific challenges, expanding its applicability:

High-Tg FR4: With glass transition temperatures (Tg) of 150–200°C, these variants resist softening in high-heat environments. Novolac-based high-Tg FR4, for instance, maintains structural integrity in automotive underhood systems where temperatures reach 120°C, outperforming standard FR4 (Tg 130–140°C) by 30–50% in thermal cycling tests.

Low-Dk FR4: Modified resins and glass fibers reduce the dielectric constant (Dk = 3.8–4.2 at 1 GHz), minimizing signal loss in high-speed designs. These variants are critical for 5G small cells and data center switches, where maintaining signal integrity at frequencies up to 10 GHz is essential.

Halogen-Free FR4: Using phosphorus or nitrogen-based flame retardants, these laminates eliminate bromine and chlorine, meeting strict environmental standards in medical devices and consumer electronics. They offer comparable mechanical strength to traditional FR4 but with 40–50% lower toxic gas emission during combustion.

Thin-Core FR4: Laminates as thin as 0.05 mm enable flexible-rigid PCBs, ideal for wearables and foldable devices. These thin cores maintain 80% of the flexural strength of standard FR4, allowing repeated bending without cracking.

Each variant extends FR4’s capabilities into niche applications, ensuring its relevance across industries.

Advancements in manufacturing are enhancing FR4 PCB quality, efficiency, and environmental friendliness:

Automated Lamination: Computer-controlled presses with real-time temperature and pressure monitoring reduce void formation to <1% (from 5–10% in manual processes). This improves thermal conductivity by 10–15% and ensures uniform dielectric properties across the laminate.

Laser Drilling: Replacing mechanical drills for microvias (diameters <0.1 mm), laser drilling achieves precision of ±5 μm, enabling higher component density in HDI (high-density interconnect) PCBs. This is critical for smartphones and IoT devices with shrinking form factors.

Eco-Friendly Etching: Acid-free etchants (e.g., ferric chloride alternatives) reduce wastewater treatment costs by 30% while cutting heavy metal emissions. Some manufacturers now recover and reuse copper from etching solutions, boosting material efficiency to 95%.

3D Printing for Prototyping: Additive manufacturing with FR4-compatible inks (epoxy mixed with glass microfibers) allows rapid prototyping of complex geometries, such as integrated heat sinks or curved traces. These prototypes match 80% of standard FR4’s mechanical properties, accelerating design cycles by 40–60%.

These innovations not only improve performance but also align with the industry’s shift toward sustainability.

FR4 PCB’s performance is defined by a set of critical metrics that determine its suitability for different applications:

Electrical Insulation: Volume resistivity ≥10¹⁴ Ω·cm and dielectric strength ≥20 kV/mm ensure minimal leakage current, even in high-voltage applications like industrial motor drives.

Thermal Conductivity: Standard FR4 offers 0.2–0.3 W/mK, sufficient for low-power devices. Thermally enhanced variants, with ceramic fillers (alumina, boron nitride), reach 0.5–1.0 W/mK, supporting 5–20W components without active cooling.

Mechanical Strength: Flexural strength ≥500 MPa and modulus ≥20 GPa allow FR4 PCBs to withstand assembly stresses and operational vibration, from consumer gadgets to industrial machinery.

Dimensional Stability: Low coefficient of thermal expansion (CTE: 12–18 ppm/°C in-plane) minimizes warpage during temperature changes, ensuring solder joint reliability in thermal cycling (e.g., -40°C to +125°C).

These properties make FR4 a versatile choice, balancing performance with cost across a wide range of power and frequency requirements.

FR4 PCB’s adaptability ensures its use in diverse sectors, each leveraging its unique properties:

Consumer Electronics: Smartphones, laptops, and wearables rely on thin-core, low-Dk FR4 for compact designs and high-speed data transmission. For example, 5G smartphones use 12–16 layer HDI FR4 PCBs with microvias to support 10+ antennas.

Automotive: High-Tg FR4 (170°C+) is used in ADAS (advanced driver-assistance systems) and battery management systems (BMS), where resistance to thermal cycling and chemical exposure (oils, coolants) is critical.

Industrial Automation: Rugged FR4 variants with thick copper (4–6 oz) handle high currents in motor drives and PLCs (programmable logic controllers), ensuring reliable operation in factory environments.

Medical Devices: Halogen-free FR4 is preferred for patient monitors and diagnostic equipment, where biocompatibility and low toxicity are essential. Its stability under sterilization (autoclaving, ethylene oxide) ensures long-term reliability.

Renewable Energy: Inverters for solar panels and wind turbines use high-Tg FR4 to withstand outdoor temperature extremes, withstanding -40°C to +85°C without performance degradation.

Engineers must address several factors to maximize FR4 PCB performance:

Impedance Control: For high-speed signals, trace width, copper thickness, and dielectric spacing are optimized to achieve target impedance (e.g., 50 Ω for RF). Low-Dk FR4 reduces the required trace width by 15–20% compared to standard FR4, saving space.

Thermal Management: For components >5W, thermal vias (filled with conductive epoxy) and copper pours distribute heat. A 3x3 array of 0.3 mm vias can reduce component temperature by 10–15°C in standard FR4.

Mechanical Stress: Mounting holes and edge connectors should be placed to avoid stress concentrations, especially in thin-core FR4. Rounded corners reduce cracking risk during assembly.

Solder Mask Selection: UV-cured solder masks with high Tg (>150°C) prevent delamination in high-heat areas, such as near power transistors. Matte finishes reduce glare in optical sensors, improving accuracy.

By addressing these considerations, designers can leverage FR4’s strengths while mitigating its limitations.

Rigorous testing ensures FR4 PCBs meet performance standards:

IPC Compliance: Most FR4 PCBs adhere to IPC-4101, which specifies material properties (Tg, CTE, flame resistance). High-reliability applications (aerospace, medical) require IPC-6012 Class 3 certification, with stricter testing for via integrity and thermal endurance.

Thermal Cycling: PCBs undergo 1,000+ cycles of -40°C to +125°C to test solder joint and via reliability. High-Tg FR4 typically shows <1% failure rate, compared to 5–10% for standard FR4 in these tests.

Signal Integrity Testing: Network analyzers measure insertion loss and return loss up to 10 GHz, verifying low-Dk FR4 performance in high-speed designs.

Mechanical Testing: Flexural strength and peel strength (copper adhesion) are tested per IPC-TM-650, ensuring the PCB withstands handling and operational stresses.

The FR4 PCB industry is making strides in reducing its environmental footprint:

Recycling: Waste FR4 is ground into filler for new laminates, reducing virgin material use by 30–40%. Copper is recovered via pyrolysis or hydrometallurgy, with 90%+ recycling efficiency.

Low-VOC Manufacturing: Water-based solder masks and UV-cured resins reduce volatile organic compound (VOC) emissions by 70–80% compared to solvent-based alternatives.

Energy Efficiency: Automated lamination and laser drilling reduce energy consumption by 20–25% per PCB, lowering carbon footprints.

Bio-Based Epoxies: Emerging formulations use plant-derived resins (soybean, castor oil) to replace petroleum-based epoxies, reducing carbon emissions by 25–30% while maintaining Tg and mechanical strength.

Several innovations are poised to enhance FR4’s capabilities:

Nano-Enhanced FR4: Graphene or carbon nanotube (CNT) additives improve thermal conductivity to 1.0–1.5 W/mK, bridging the gap between FR4 and metal-core PCBs. Lab tests show 40% better heat dissipation than standard FR4.

Smart FR4: Embedded sensors (temperature, strain) in the laminate enable real-time health monitoring, predicting failures in critical applications (e.g., aerospace, medical). These sensors add <5% to PCB cost but extend lifespan by 30–50%.

3D Integrated FR4: Layered designs with embedded components (resistors, capacitors) reduce size and improve signal integrity. This "system-in-package" approach is ideal for IoT devices, where miniaturization is key.

Circular Economy Models: Manufacturers are exploring take-back programs for end-of-life FR4 PCBs, creating closed-loop recycling systems that further reduce waste.

FR4 PCB’s enduring success stems from its unique blend of performance, cost, and adaptability. As material science and manufacturing techniques advance, it continues to meet the demands of emerging technologies—from 5G to renewable energy—while addressing sustainability concerns. Its ability to evolve through specialized variants (high-Tg, low-Dk, halogen-free) ensures it remains the material of choice for most electronic applications. For engineers, understanding FR4’s properties and design considerations is key to creating reliable, cost-effective devices. As the electronics industry pushes toward higher power, faster speeds, and greater sustainability, FR4 PCB is poised to remain at the forefront, proving that even the most established materials can drive innovation.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB