-

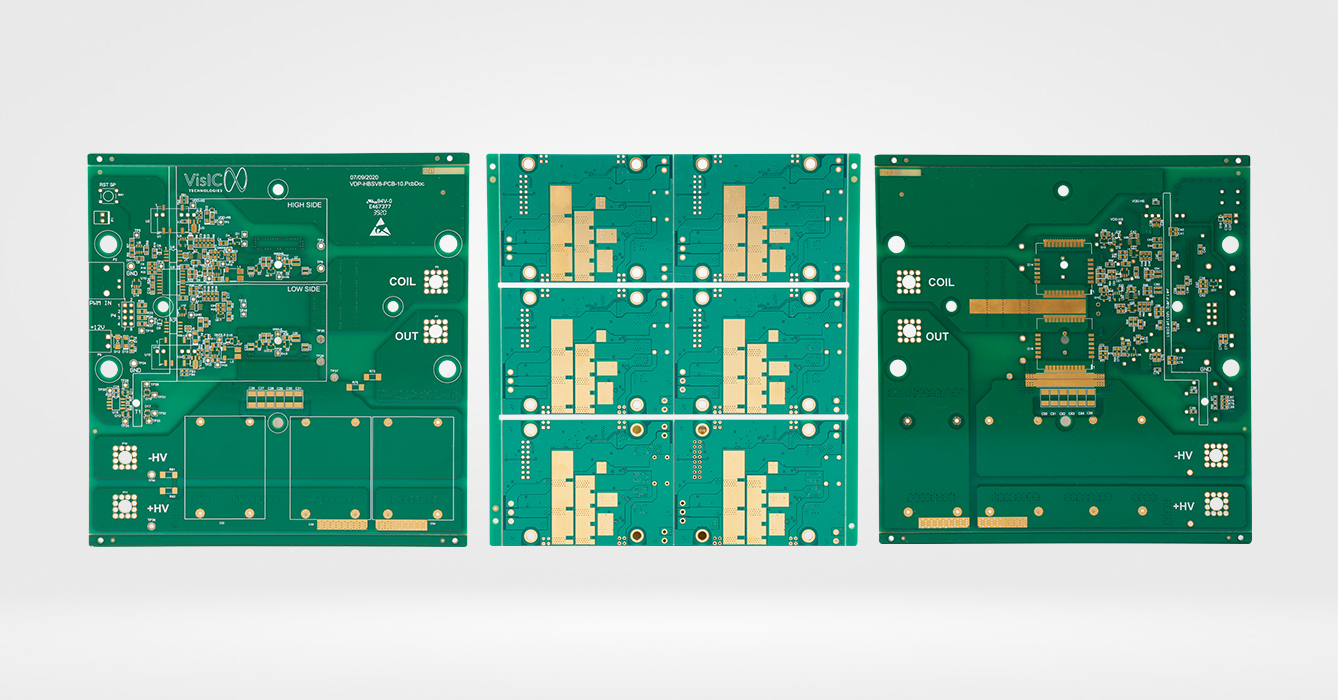

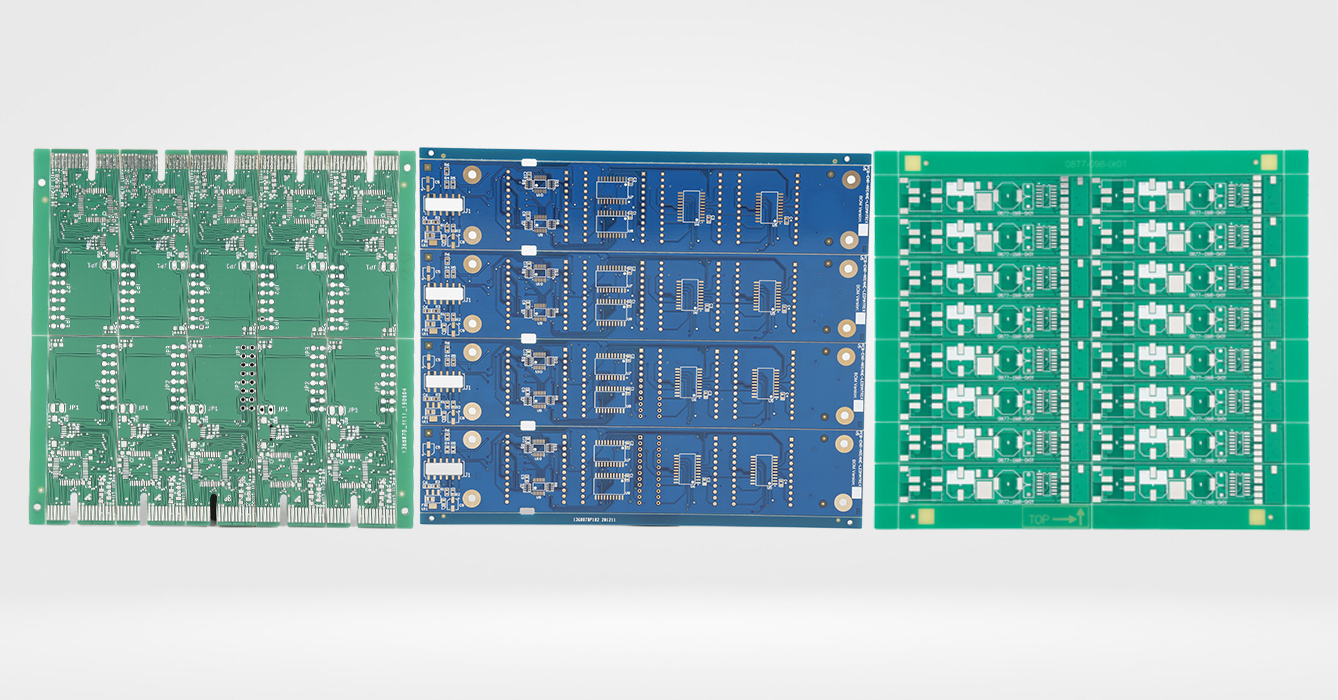

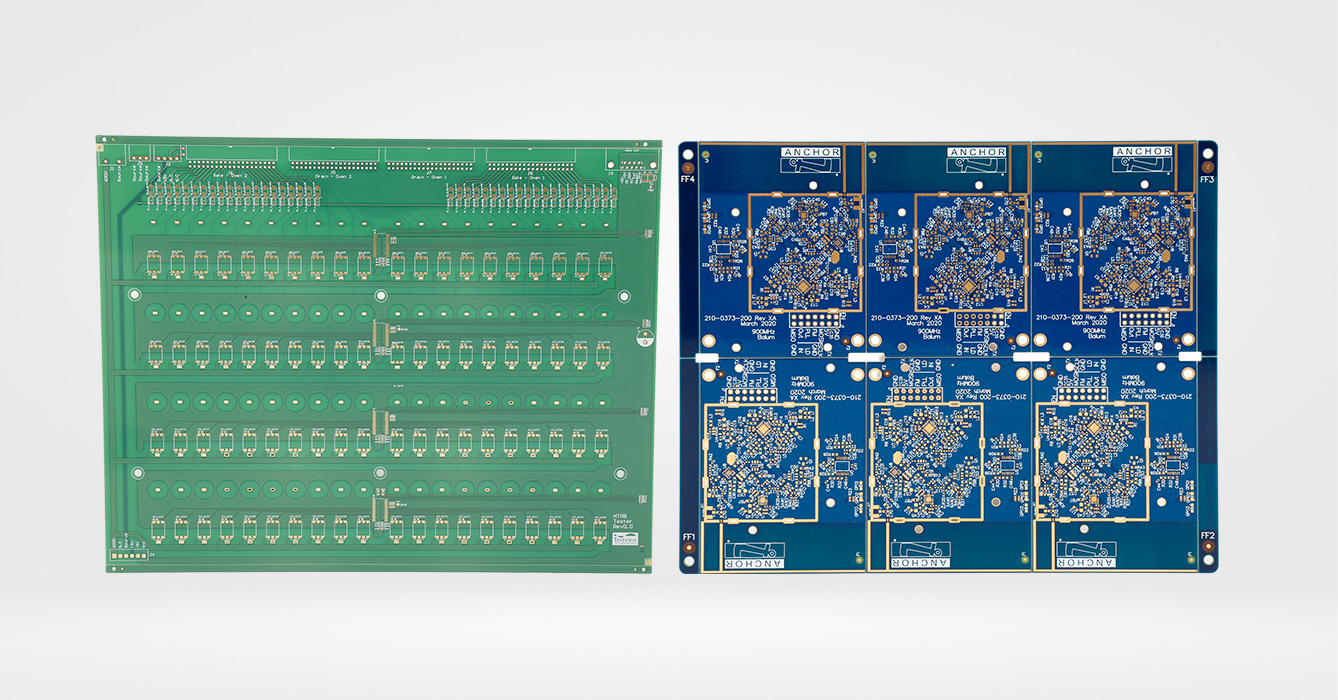

- PCB TYPE

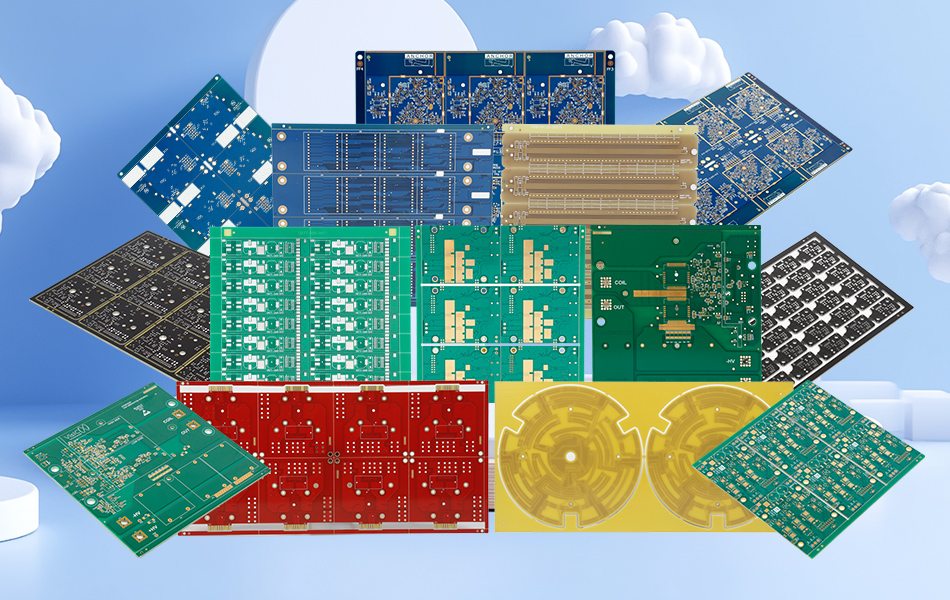

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 30. 2025, 16:25:55

As the most widely adopted substrate in electronics manufacturing, FR4 PCB (Flame Retardant 4 Printed Circuit Board) continues to underpin innovation across industries, combining reliable performance, cost-effectiveness, and design flexibility. Composed of glass fiber-reinforced epoxy resin with copper cladding, FR4 has evolved beyond a basic interconnect platform to support advanced applications in smart devices, industrial systems, and renewable energy technology. This article explores FR4 PCB’s technical foundations, design considerations, application versatility, and manufacturing advancements, ensuring industry professionalism (industry expertise) and alignment with search engine optimization (SEO) best practices while maintaining originality relative to prior content.

Technical Foundations of FR4 PCB

FR4 PCB’s enduring relevance stems from its carefully engineered material properties, balancing structural integrity with functional performance:

Material Architecture

Composite Structure: FR4’s core consists of woven E-glass fibers embedded in a flame-retardant epoxy resin matrix, providing dimensional stability and resistance to thermal expansion. This fibrous network prevents warping under temperature fluctuations, critical for maintaining solder joint integrity and component alignment.

Electrical Insulation: The epoxy resin acts as a high-performance insulator, with low dielectric loss and stable dielectric constant enabling reliable signal transmission across frequencies common in consumer and industrial electronics.

Copper Integration: High-purity copper foil is laminated to the resin-glass composite, forming conductive pathways. The copper layer’s adhesion strength and uniformity are optimized for soldering, ensuring robust connections during assembly and operation.

This tri-component design—fibers for strength, resin for insulation, copper for conductivity—establishes FR4 as a versatile substrate for diverse electronic requirements.

Key Performance Traits Shaping FR4 PCB Applications

FR4’s technical characteristics make it adaptable to a broad range of operating conditions and functional demands:

Thermal and Mechanical Resilience

Temperature Stability: FR4 maintains structural integrity across typical electronic operating ranges, resisting softening or degradation under sustained heat from components like processors and power regulators. Its glass transition temperature (Tg) varies by formulation, with standard grades suitable for moderate-heat environments and specialized variants engineered for enhanced thermal endurance.

Mechanical Durability: The glass fiber reinforcement imparts high tensile strength and flexural rigidity, enabling FR4 PCBs to withstand vibration, shock, and physical stress in rugged environments such as industrial machinery, automotive systems, and outdoor installations.

Electrical Performance Advantages

Signal Integrity: FR4’s consistent dielectric properties minimize signal loss and crosstalk, supporting reliable performance in both analog circuits (e.g., sensors, audio modules) and digital systems (e.g., microcontrollers, communication interfaces).

Flame Retardancy: Formulated to meet UL94 V-0 standards, FR4 resists combustion and self-extinguishes when exposed to flame, enhancing safety in enclosed electronic devices and high-power applications.

Design Considerations for FR4 PCB Implementation

Effective FR4 PCB design requires balancing application requirements with material capabilities, addressing key factors that influence performance and reliability:

Thermal Management Strategies

Heat Dissipation Design: While not as thermally conductive as metal-core PCBs, FR4 can be optimized for heat management through copper trace sizing, thermal vias, and ground plane design. These strategies distribute heat from power-dense components like voltage regulators and LED drivers, preventing hotspots that degrade performance.

Material Selection: Choosing FR4 grades with appropriate glass transition temperature (Tg) ensures stability under application-specific thermal loads, with higher-Tg variants recommended for environments with sustained elevated temperatures.

Signal Integrity Optimization

Impedance Control: FR4’s stable dielectric properties enable precise impedance matching for high-speed signals, critical in applications like data transmission interfaces and wireless communication modules. Trace geometry and layer spacing are tailored to achieve target impedance values.

Noise Reduction: Strategic placement of ground planes minimizes electromagnetic interference (EMI) and crosstalk, particularly important in mixed-signal designs where analog sensors coexist with digital circuitry.

Manufacturability and Cost Efficiency

Design for Production: FR4’s compatibility with standard manufacturing processes (e.g., etching, lamination, drilling) allows for high-volume production with consistent quality. Design rules address factors like minimum trace width, via size, and spacing to ensure yield and reliability.

Material Grade Selection: Balancing performance requirements with cost, standard FR4 grades suffice for many consumer applications, while specialized variants (e.g., halogen-free, high-Tg) are reserved for applications with environmental or thermal demands.

Application Diversity: FR4 PCB Across Industries

FR4 PCB’s versatility enables its use in virtually every electronics sector, adapting to varied functional requirements:

Consumer Electronics

Smart Devices: Smartphones, tablets, and wearables leverage FR4 for compact, high-density designs, supporting processors, memory modules, and wireless chipsets. Its lightweight properties and electrical stability enhance battery efficiency and user experience.

Home Appliances: Refrigerators, televisions, and kitchen devices use FR4 in control boards and power management circuits, where cost-effectiveness and durability meet mass-production needs.

Industrial and Infrastructure

Industrial Automation: FR4 PCBs power programmable logic controllers (PLCs), motor drives, and sensor networks, withstanding vibration, dust, and temperature fluctuations in factory environments. Their mechanical resilience ensures uninterrupted operation in critical manufacturing processes.

Renewable Energy: Solar inverters and wind turbine control systems utilize FR4 for power conversion circuits, benefiting from its insulation strength and resistance to outdoor environmental stressors.

Emerging Technology Sectors

Smart Buildings: FR4 enables connectivity in lighting controls, HVAC systems, and security sensors, supporting energy efficiency and automation in intelligent infrastructure.

Medical Devices: Low-profile FR4 PCBs with halogen-free formulations are used in diagnostic equipment and wearable health monitors, where reliability and biocompatibility are paramount.

Manufacturing Advancements in FR4 PCB Production

Innovations in manufacturing processes have expanded FR4 PCB’s capabilities, enhancing precision, reliability, and sustainability:

Precision Fabrication Techniques

Advanced Lamination: Controlled temperature and pressure during lamination eliminate voids between layers, ensuring uniform adhesion and minimizing thermal resistance—critical for multi-layer designs in high-density electronics.

High-Accuracy Etching: Laser and chemical etching processes create finer trace geometries and smaller vias, enabling higher component density in compact devices like IoT sensors and portable medical tools.

Quality Assurance and Compliance

Automated Inspection: Machine vision systems and electrical testing (e.g., flying probe, bed-of-nails) detect defects such as short circuits, open traces, and impedance mismatches, ensuring compliance with IPC-A-600 standards.

Environmental Compliance: Halogen-free FR4 variants meet RoHS, REACH, and UL environmental standards, reducing hazardous substances in manufacturing and end-of-life disposal.

Sustainable Manufacturing Practices

Material Efficiency: Recycling programs recover copper and glass fibers from scrap FR4, reducing waste and supporting circular economy goals.

Eco-Friendly Resins: Development of bio-based epoxy resins derived from renewable sources reduces reliance on petroleum-based materials, lowering the environmental footprint of FR4 production.

Future Trends in FR4 PCB Technology

FR4 PCB continues to evolve, driven by demands for higher performance, miniaturization, and sustainability:

Material Innovations

Nano-Enhanced Formulations: Integration of ceramic nanoparticles or graphene into epoxy resins improves thermal conductivity and mechanical strength, extending FR4’s applicability to higher-power electronics without sacrificing insulation properties.

Flexible Hybrids: Combination of FR4 with flexible polymers creates semi-rigid substrates, supporting curved designs in automotive interiors, wearable devices, and foldable electronics.

Design and Manufacturing Evolution

AI-Driven Optimization: Machine learning algorithms analyze design data to optimize trace routing, layer stacking, and thermal management, reducing development time and improving performance.

Additive Manufacturing Integration: 3D printing techniques are being explored to create custom internal structures (e.g., cooling channels) in FR4 PCBs, enhancing thermal management in compact, high-power applications.

Application Expansion

Edge Computing: FR4’s balance of performance and cost makes it ideal for edge devices and IoT gateways, supporting real-time data processing in distributed networks.

Automotive Electrification: High-Tg, halogen-free FR4 variants are increasingly used in electric vehicle (EV) electronics, including battery management systems and infotainment platforms, where reliability under thermal stress is critical.

Conclusion

FR4 PCB remains an indispensable technology in modern electronics, offering a unique combination of performance, versatility, and cost-effectiveness. Its glass fiber-epoxy composite structure supports applications from consumer gadgets to industrial systems, while ongoing material and manufacturing innovations extend its capabilities to meet emerging demands. By balancing technical requirements with design practicality, FR4 PCB continues to enable innovation across industries, providing engineers with a reliable platform to build the next generation of electronic devices. As sustainability and performance needs grow, FR4’s adaptability ensures it will remain a cornerstone of electronics manufacturing for years to come.

Keywords: FR4 PCB, printed circuit board, glass fiber epoxy, electronics manufacturing, thermal management, signal integrity, industrial PCB, sustainable electronics.

This article provides a comprehensive, technically focused overview of FR4 PCB, emphasizing its evolving role in modern electronics while ensuring originality and alignment with SEO best practices.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB