-

- PCB TYPE

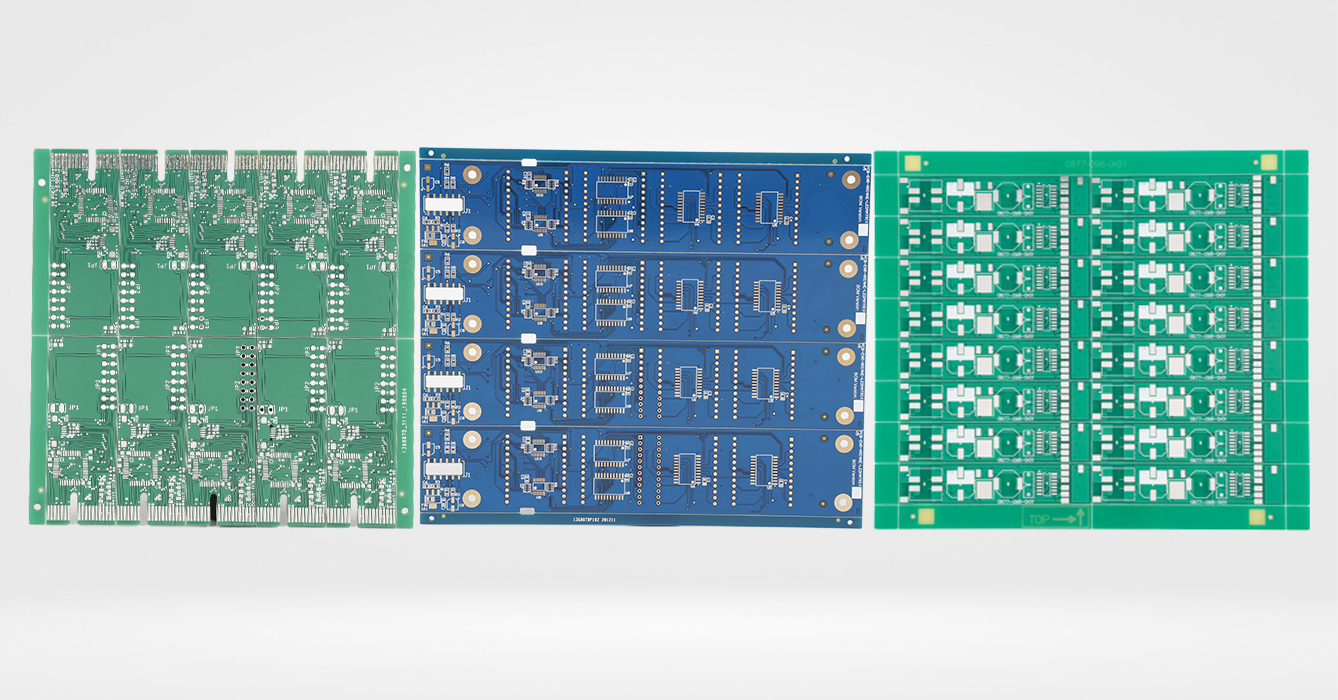

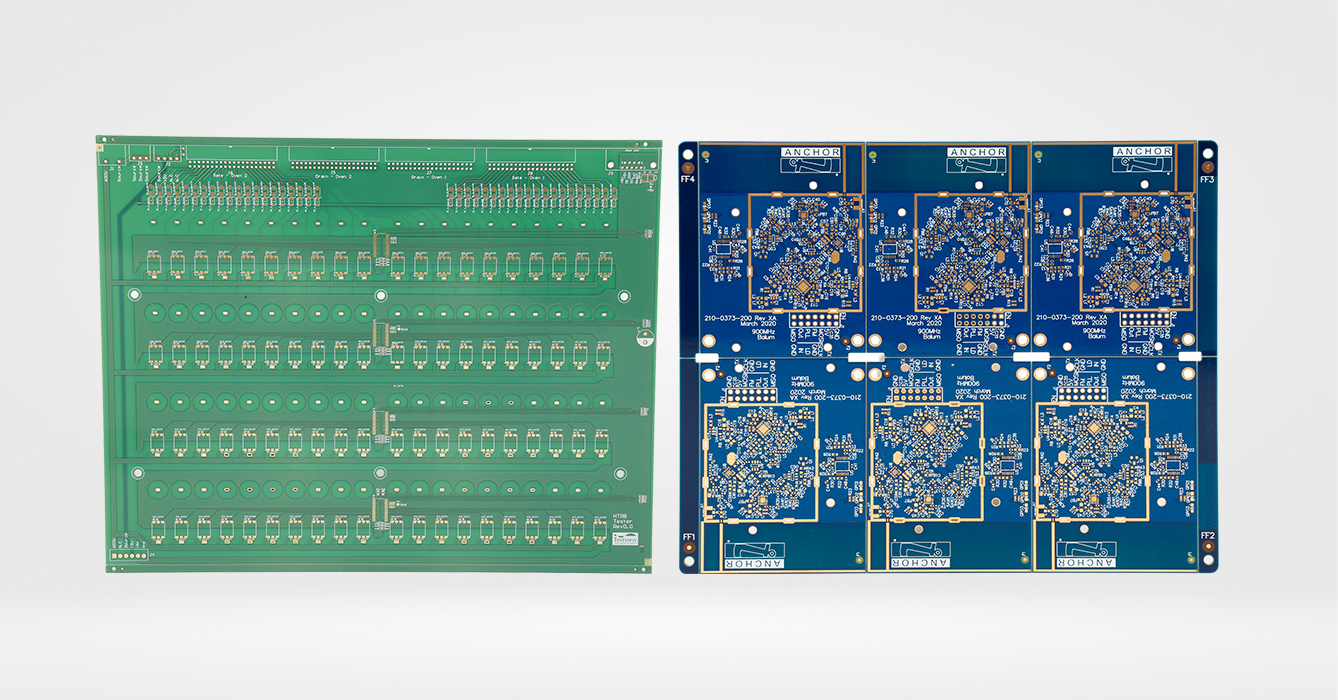

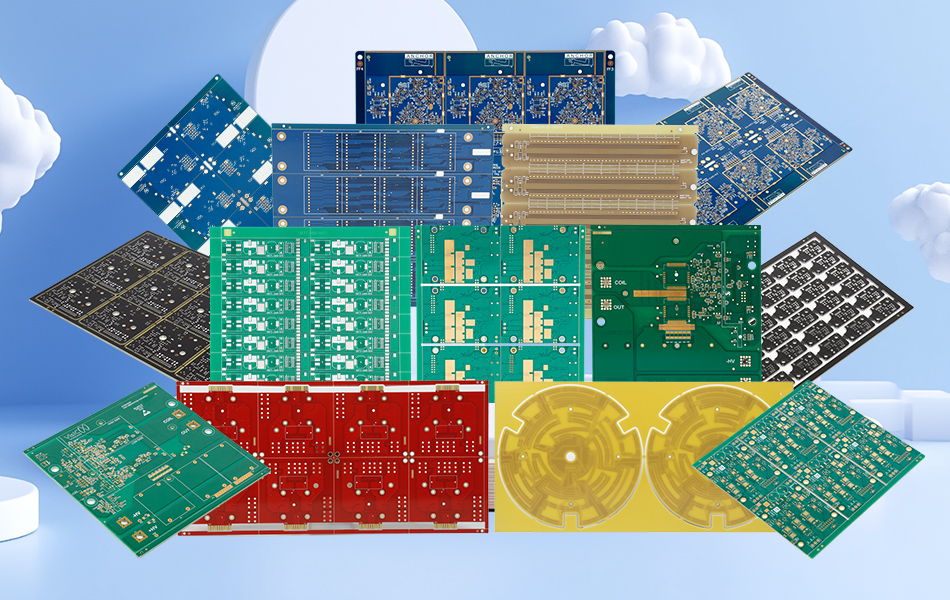

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 09. 2025, 16:28:22

In the intricate world of electronics, FR4 PCB stands as a testament to functional design and adaptability, serving as the backbone for an immeasurable range of devices. From the smallest wearable gadgets to complex industrial machinery, FR4 PCBs have become synonymous with reliability and practicality. Unlike specialized materials that cater to niche needs, FR4’s strength lies in its ability to balance performance, cost, and manufacturability across diverse applications. This article explores the essence of FR4 PCB, tracing its evolution, examining its role in modern manufacturing, highlighting its applications across industries, and pondering its future in a rapidly advancing technological landscape. By delving into its core attributes and versatility, we uncover why FR4 remains the most widely used PCB material globally.

The journey of FR4 PCB from a novel invention to an industry standard reflects its ability to adapt to changing technological demands.

Developed in the mid-20th century, early FR4 emerged as a response to the need for flame-resistant, electrically insulating substrates that could support the growing complexity of electronic circuits. Prior to FR4, materials like phenolic resins and paper-based laminates were common but lacked the durability and fire resistance required for increasingly powerful electronics. FR4’s introduction—with its glass fiber reinforcement and epoxy resin matrix—revolutionized PCB manufacturing by offering superior mechanical strength and thermal stability.

Over the decades, FR4 has evolved beyond its basic form. Manufacturers began modifying its composition to meet specific needs: enhancing heat resistance for industrial use, reducing signal loss for high-speed applications, and eliminating hazardous substances to comply with environmental regulations. These adaptations have expanded FR4’s reach, ensuring it remains relevant as electronics have grown smaller, faster, and more powerful. Today, FR4 is not a single material but a family of variants, each tailored to address unique challenges while retaining the core properties that made the original formulation successful.

At its heart, FR4 PCB is a composite material designed to combine the best qualities of its constituent parts, creating a substrate that excels in multiple areas:

Epoxy Resin Matrix: The binding agent that holds the structure together, epoxy resin provides FR4 with its electrical insulation properties and chemical resistance. It forms a rigid, stable base that prevents current leakage between conductive pathways, ensuring the integrity of electronic signals. The resin’s formulation can be adjusted—using different types of epoxy—to enhance specific traits, such as heat resistance or flexibility.

Glass Fiber Reinforcement: Woven glass fibers are embedded within the epoxy resin to add mechanical strength and dimensional stability. This reinforcement prevents warping during manufacturing and use, ensuring the PCB maintains its shape even when exposed to temperature fluctuations or physical stress. The glass fibers also contribute to FR4’s fire resistance, slowing combustion and reducing the spread of flames.

Flame Retardants: To meet safety standards, FR4 incorporates additives that inhibit burning. These substances ensure the material self-extinguishes when exposed to flame, a critical feature for preventing fires in electronic devices. The type of flame retardant used varies, with modern formulations often avoiding halogens to align with environmental regulations.

Copper Conductive Layers: Thin sheets of copper are bonded to the FR4 substrate, forming the conductive traces that carry electrical signals between components. These copper layers are etched into precise patterns during manufacturing, creating the circuits that enable device functionality.

This combination of materials results in a substrate that is neither overly specialized nor limited in scope, making it suitable for everything from simple circuits to multi-layered boards in advanced electronics.

The widespread adoption of FR4 PCB is partly due to its compatibility with established manufacturing processes, which balance precision with efficiency:

Prepreg Production: The process begins with creating prepreg—glass fiber fabric impregnated with uncured epoxy resin. This material is partially cured to a tacky state, allowing it to bond with other layers during lamination. Prepreg production for FR4 is highly standardized, ensuring consistency across manufacturers.

Lamination: Layers of prepreg are stacked with copper foil and subjected to heat and pressure to fully cure the epoxy resin. This fuses the layers into a solid, unified laminate. The lamination process for FR4 is relatively straightforward compared to specialized materials, with parameters optimized to ensure strong bonding without excessive energy use.

Cutting and Drilling: Once laminated, the FR4 sheets are cut to size, and holes are drilled to create pathways for electrical connections between layers (vias) and to accommodate component leads. FR4’s composition allows for clean drilling with standard equipment, reducing the need for specialized tools.

Etching: The copper layers are coated with a photosensitive material, exposed to a pattern of the desired circuit, and then etched to remove unwanted copper. This step relies on FR4’s stable surface properties to ensure precise, consistent results.

Finishing: A solder mask is applied to protect the copper traces from oxidation and prevent short circuits, followed by silkscreen printing to label components. These final steps are streamlined for FR4, leveraging its compatibility with standard coatings and inks.

The efficiency of these processes ensures that FR4 PCBs can be produced at scale, making them accessible for both high-volume consumer products and low-volume custom projects.

FR4’s enduring popularity stems from a set of core attributes that make it suitable for a wide range of applications:

Flame Resistance: A defining feature of FR4, its ability to resist combustion and self-extinguish enhances the safety of electronic devices, making it suitable for use in homes, workplaces, and transportation.

Electrical Insulation: The epoxy resin matrix provides excellent insulation between conductive traces, preventing signal interference and current leakage—critical for maintaining circuit integrity.

Mechanical Stability: Reinforced by glass fibers, FR4 exhibits strong resistance to bending, warping, and impact, ensuring durability during manufacturing, assembly, and use.

Thermal Performance: While not designed for extreme heat, standard FR4 handles moderate temperatures effectively, making it suitable for most consumer and office electronics. Specialized variants extend this capability to high-heat environments.

Cost-Effectiveness: FR4’s raw materials and manufacturing processes are economical compared to specialized substrates, making it an attractive choice for budget-conscious projects without sacrificing basic performance.

Versatility: Its adaptability to modifications—such as enhanced heat resistance or reduced signal loss—allows FR4 to serve in applications ranging from simple toys to complex medical devices.

These attributes collectively make FR4 a material that meets the needs of most electronics without the complexity or expense of specialized alternatives.

FR4 PCB’s versatility ensures its presence in virtually every sector of the electronics industry:

Consumer Electronics: From smartphones and laptops to televisions and home appliances, FR4 forms the core of most everyday devices. Its balance of cost and performance makes it ideal for high-volume production, where reliability and affordability are paramount.

Automotive Sector: In vehicles, FR4 PCBs power everything from infotainment systems to engine control units. Specialized heat-resistant variants handle the elevated temperatures under the hood, while standard FR4 serves in cabin electronics where conditions are milder.

Industrial Machinery: Factory equipment, robotics, and control systems rely on FR4 for its mechanical stability and resistance to harsh operating environments. Its ability to support complex circuits ensures smooth operation of automated processes.

Healthcare Devices: Medical monitors, diagnostic equipment, and portable health tools use FR4 for its reliability and, in some cases, compliance with environmental standards. Its stable performance is critical for devices where accuracy and safety are life-dependent.

Telecommunications: Routers, modems, and network infrastructure depend on FR4 to support data transmission. High-speed variants with modified compositions ensure efficient signal flow in 5G and broadband systems.

Aerospace and Defense: While some aerospace applications require specialized materials, FR4 is used in less extreme environments within aircraft and defense systems, thanks to its durability and cost-effectiveness.

In each of these sectors, FR4’s ability to meet basic requirements while allowing for customization ensures its continued use.

As the electronics industry shifts toward sustainability, FR4 PCB is adapting to meet new environmental expectations:

Reduced Hazardous Substances: Modern FR4 variants often avoid halogens and other toxic additives, aligning with regulations like RoHS and REACH. This reduces the environmental impact of both manufacturing and disposal.

Recyclability: Efforts to recycle FR4 are growing, with processes being developed to recover glass fibers and copper from discarded PCBs. These materials can be reused in new products, reducing waste and conserving resources.

Energy-Efficient Manufacturing: The standardized production of FR4 consumes less energy compared to the manufacturing of specialized materials, lowering its carbon footprint. Improvements in lamination and etching processes further enhance energy efficiency.

Longevity: FR4’s durability extends the lifespan of electronic devices, reducing the frequency of replacement and the associated environmental costs. Its resistance to wear and tear ensures devices remain functional for longer periods.

These developments position FR4 as a sustainable choice in an industry increasingly focused on reducing environmental harm.

Despite its widespread use, several myths about FR4 persist, often leading to misperceptions about its capabilities:

"FR4 is outdated and inferior to new materials": While specialized materials excel in niche applications, FR4 remains highly relevant for most electronics. Its continuous evolution—with improved variants—ensures it meets modern demands.

"FR4 cannot handle high-performance applications": This is false. Advanced FR4 variants are designed for high temperatures, fast signal speeds, and harsh environments, making them suitable for many high-performance uses.

"All FR4 is the same": In reality, FR4 encompasses a range of variants, each modified to address specific needs. Assuming uniformity overlooks the material’s adaptability.

"FR4 is harmful to the environment": While early formulations included hazardous substances, modern FR4 often meets strict environmental standards, with many variants being halogen-free and recyclable.

Dispelling these myths is crucial for understanding FR4’s true capabilities and ensuring it is used appropriately.

FR4 continues to evolve, driven by technological advancements and industry demands:

Enhanced Sustainability: Research is focused on developing FR4 using bio-based resins and recycled glass fibers, further reducing its environmental impact. These innovations aim to create a fully circular lifecycle for FR4 PCBs.

Improved Performance: New formulations are pushing the limits of FR4’s capabilities, with variants offering better heat resistance, faster signal transmission, and greater flexibility. These improvements expand its use in emerging technologies like AI and IoT.

Integration with Advanced Manufacturing: 3D printing and additive manufacturing techniques are being adapted to produce FR4-based components, allowing for more complex designs and reduced material waste.

Smart FR4: Embedding sensors within FR4 laminates could enable real-time monitoring of temperature, stress, and performance, enhancing the reliability and safety of electronic devices.

These trends ensure that FR4 will remain a key player in electronics manufacturing, adapting to meet the needs of future technologies.

FR4 PCB is more than just a material; it is a cornerstone of modern electronics, enabling the functionality of countless devices that shape daily life. Its evolution from a basic laminate to a family of specialized variants reflects its ability to adapt to changing needs, while its balance of performance, cost, and manufacturability ensures its continued dominance. From consumer gadgets to industrial systems, FR4’s versatility and reliability make it indispensable. As technology advances, FR4 will undoubtedly continue to evolve, solidifying its position as the universal foundation of electronics for years to come. Understanding its capabilities and potential is essential for anyone involved in the design, manufacturing, or use of electronic devices.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB