-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jan 04. 2026, 17:02:22

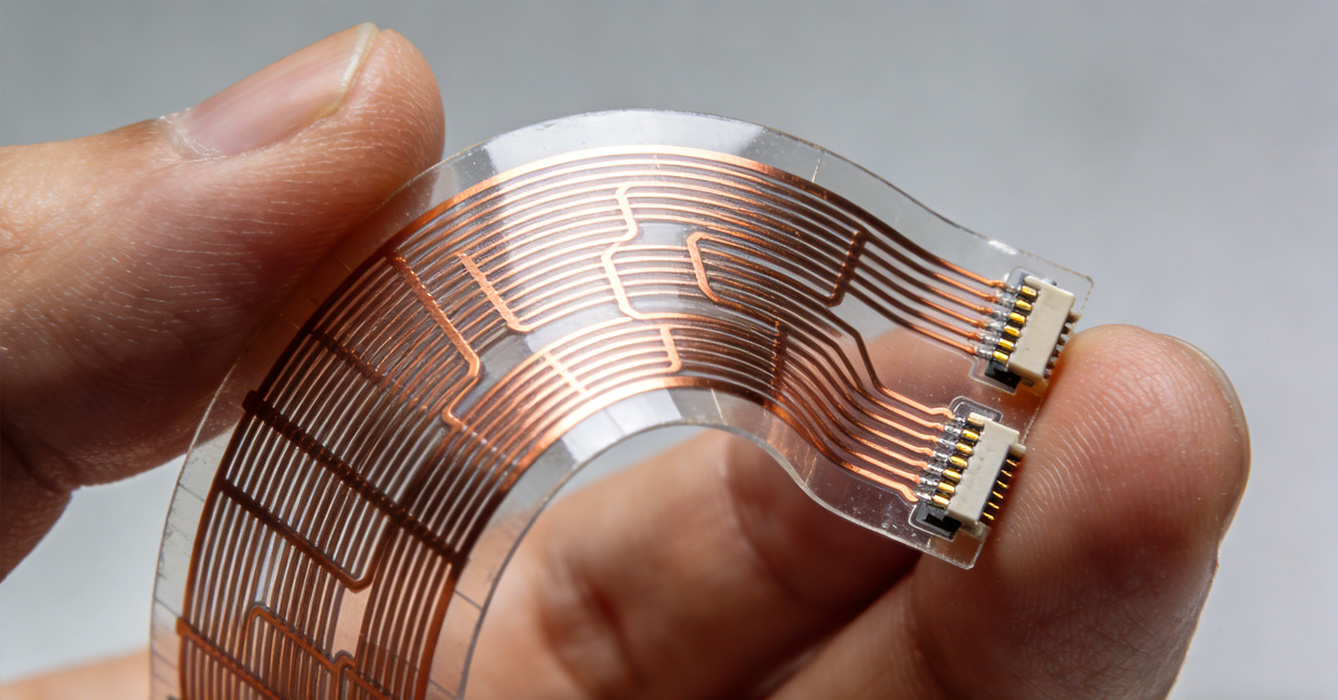

In the era of electronic miniaturization and intelligence, Flexible Circuit Assembly has evolved from a niche component process to a foundational technology that powers diverse electronic products. This assembly process leverages the inherent flexibility and compactness of flexible circuits, integrating electronic components into adaptive, space-efficient designs that overcome the limitations of rigid circuit assemblies. From everyday consumer gadgets to industrial automation systems and new energy equipment, Flexible Circuit Assembly enables seamless component integration, reliable signal transmission, and optimized product form factors. As industries pursue lighter, thinner, and more functional electronic devices, the versatility and adaptability of Flexible Circuit Assembly have made it an indispensable driver of modern electronic innovation.

The widespread adoption of Flexible Circuit Assembly stems from its unique advantages that align with the needs of contemporary electronic development. Firstly, it offers exceptional design flexibility. Unlike rigid circuit assemblies that are constrained by fixed shapes, Flexible Circuit Assembly can be tailored to fit irregular spaces, curved surfaces, or foldable structures—whether it’s the slim cavity of a wireless earbud, the contoured body of a smartwatch, or the complex layout of an industrial sensor. This flexibility allows designers to maximize space utilization and create more ergonomic, aesthetically pleasing products.

Secondly, it enhances product reliability and reduces complexity. Flexible Circuit Assembly integrates multiple circuit functions into a single flexible substrate, minimizing the need for cumbersome wiring harnesses and connectors. This integration not only simplifies the internal structure of electronic products but also reduces potential connection failure points, improving overall operational stability. Additionally, the lightweight nature of flexible circuits reduces the overall weight of products, a critical advantage for portable devices and aerospace applications.

Thirdly, it supports efficient mass production. Modern Flexible Circuit Assembly leverages automated technologies such as surface mount technology (SMT) and automated optical inspection (AOI), ensuring consistent assembly quality and high production efficiency. These automated processes reduce human error, shorten production cycles, and lower manufacturing costs, making Flexible Circuit Assembly suitable for both small-batch prototyping and large-scale mass production.

Flexible Circuit Assembly has found extensive application across a wide range of industries, driving innovation in diverse electronic products. In the consumer electronics sector, it is the backbone of smart wearables, foldable smartphones, and wireless audio devices. For example, in foldable phones, Flexible Circuit Assembly ensures that circuits can withstand repeated bending while maintaining stable signal transmission, supporting the core functionality of these innovative devices. In smartwatches, it enables the integration of sensors, displays, and batteries in a compact, lightweight design, delivering seamless user experiences.

In the industrial automation field, Flexible Circuit Assembly supports the development of intelligent sensors and control modules. Industrial sensors equipped with flexible circuit assemblies can be easily installed on machinery surfaces, adapting to harsh industrial environments such as high temperatures and vibrations. These assemblies ensure reliable data collection and signal transmission, laying the foundation for smart factory construction and predictive maintenance, which improves production efficiency and reduces downtime.

The new energy sector also benefits significantly from Flexible Circuit Assembly. In electric vehicles (EVs), it is used in battery management systems (BMS) and in-vehicle electronic control units. Flexible Circuit Assembly fits seamlessly into the tight spatial layout of EV battery packs, enabling accurate monitoring of battery performance while withstanding high-temperature operating conditions. In solar energy systems, it supports the development of flexible solar panels, facilitating installation on irregular surfaces such as building facades and curved roofs.

Choosing the right Flexible Circuit Assembly partner is crucial to ensuring product quality and production efficiency. Firstly, evaluate the partner’s technical expertise and production capabilities. A reliable partner should have extensive experience in flexible circuit assembly, proficient in automated assembly technologies and quality control processes. They should also be able to handle diverse customization needs, adapting to different industry requirements and product designs.

Secondly, verify their quality management system. High-quality Flexible Circuit Assembly requires rigorous quality control throughout the production process. Look for partners with established quality certifications such as ISO 9001, and comprehensive testing protocols including electrical performance testing, mechanical durability testing, and environmental resistance testing. These measures ensure that the assembled circuits meet the required performance and reliability standards.

Finally, consider their supply chain stability and service capabilities. A good partner should have a stable supply chain of high-quality raw materials, ensuring uninterrupted production. Additionally, they should offer responsive technical support and after-sales service, addressing any issues that arise during the assembly process and providing timely solutions to keep projects on track.

As the electronic industry continues to evolve, Flexible Circuit Assembly is moving toward higher precision, intelligence, and sustainability. One key trend is the integration of advanced technologies such as AI and IoT into assembly processes. AI-driven quality inspection systems enhance defect detection accuracy, while IoT-enabled production monitoring enables real-time tracking of assembly progress, improving production efficiency and quality control.

Sustainability is another growing focus. Manufacturers are increasingly adopting eco-friendly materials such as recyclable substrates and lead-free solders in Flexible Circuit Assembly. Energy-efficient production processes are also being promoted to reduce carbon emissions, aligning with global environmental protection goals. Additionally, the development of stretchable flexible circuit assemblies will further expand application boundaries, enabling innovative products such as smart clothing and skin-like sensors.

In conclusion, Flexible Circuit Assembly is a versatile and indispensable technology in modern electronic innovation, supporting the development of diverse products across consumer electronics, industrial automation, and new energy sectors. Its design flexibility, reliability, and efficiency make it a key enabler of product differentiation and technological advancement. By selecting a reliable assembly partner with strong technical expertise and quality control capabilities, businesses can fully leverage the value of Flexible Circuit Assembly to create high-performance, competitive electronic products. As precision, intelligence, and sustainability trends deepen, Flexible Circuit Assembly will continue to play a critical role in shaping the future of the electronic industry.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB