-

- PCB TYPE

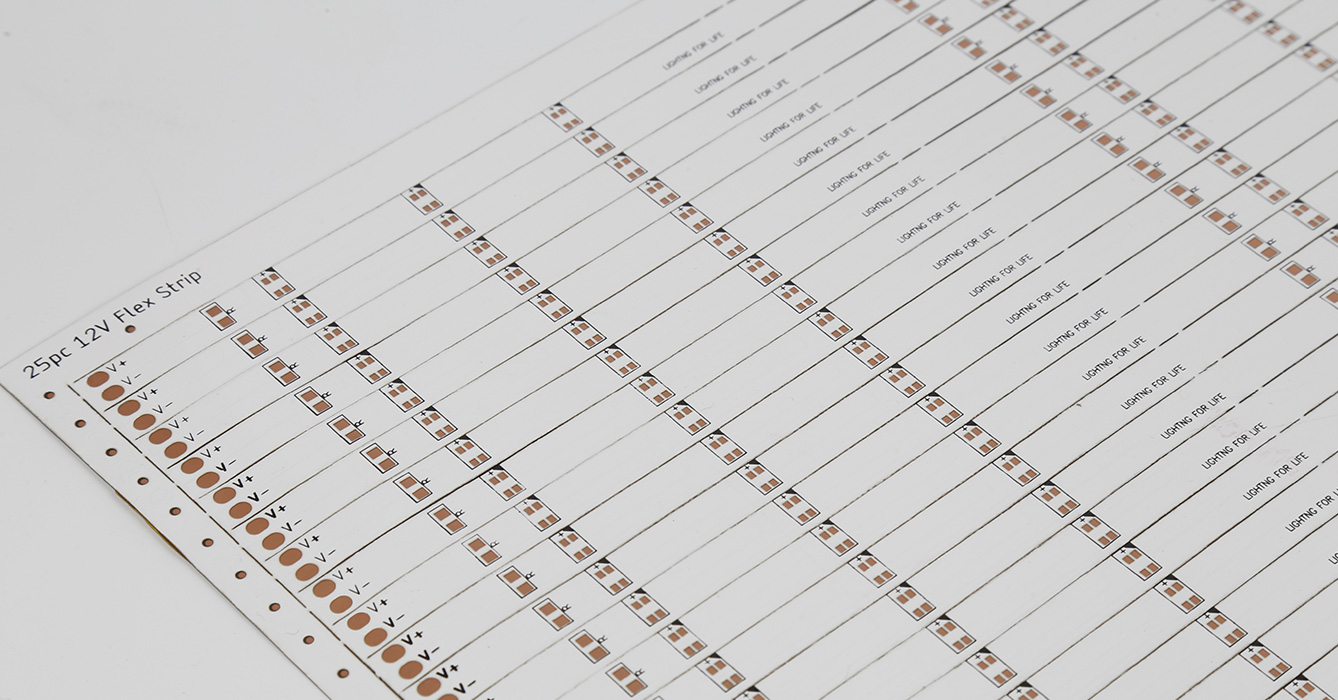

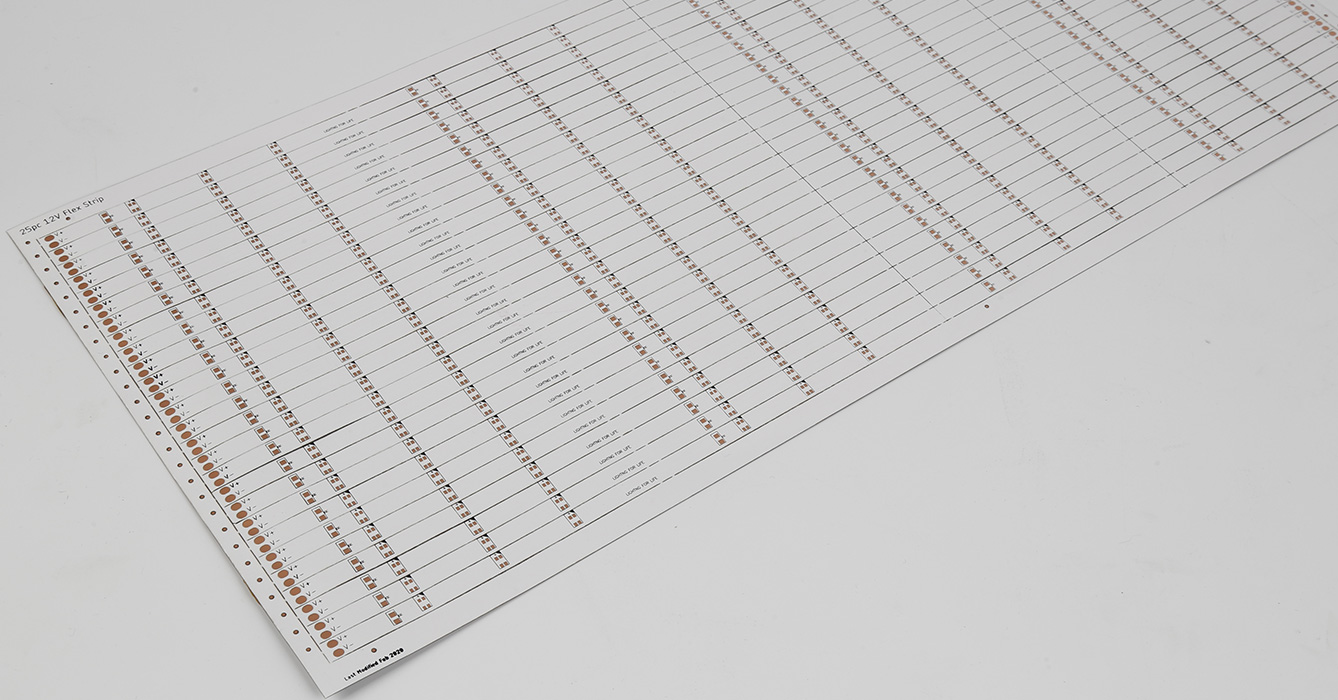

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 12. 2025, 11:34:06

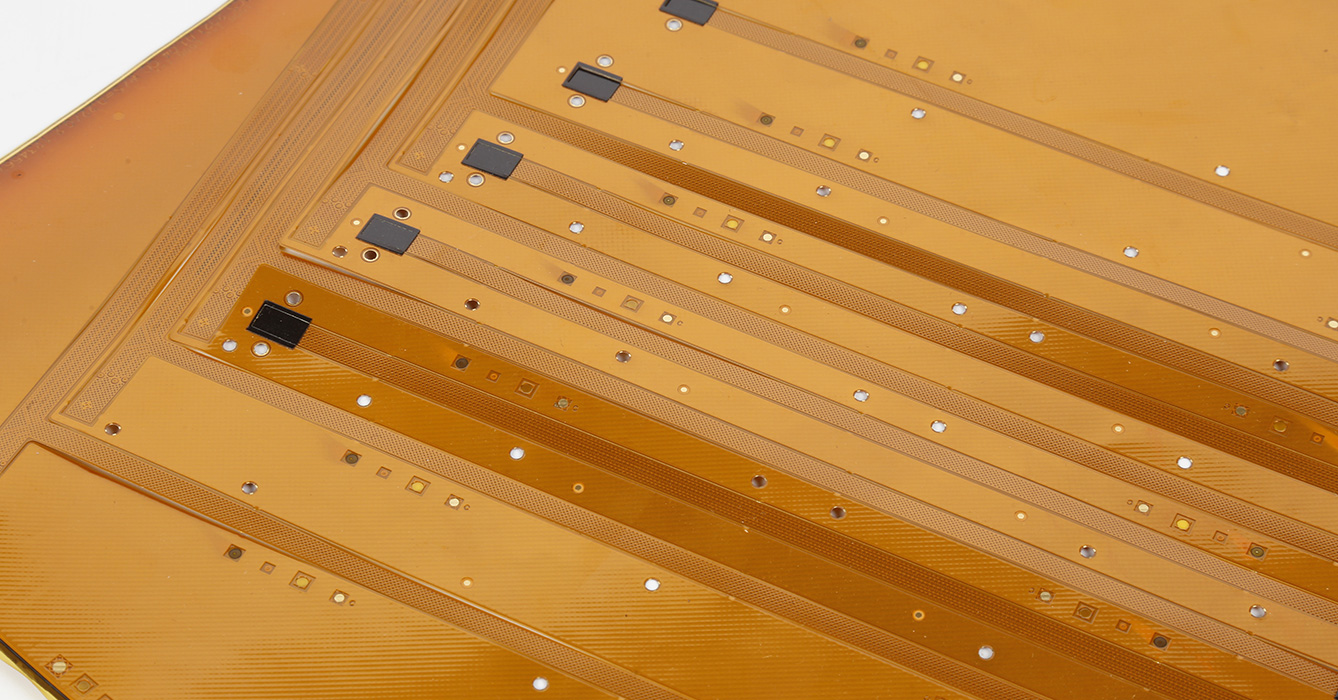

Flexible printed circuits (FPCs) have become indispensable components in the digital transformation of industries ranging from industrial automation and medical technology to consumer electronics and new energy. A professional Flexible PCB Supplier distinguishes itself by building a customized solution ecosystem centered on cross-industry collaboration and technological innovation, going beyond simple component supply to act as a strategic partner in clients’ product development journeys. Unlike generic component providers, top Flexible PCB Suppliers deeply understand the unique technical pain points of different industries, delivering tailored FPC solutions that balance flexibility, performance, and integration efficiency. For brands aiming to innovate in their respective sectors, partnering with a versatile Flexible PCB Supplier is critical to translating technical concepts into market-competitive products.

The core competitiveness of a leading Flexible PCB Supplier lies in its ability to bridge industry boundaries through collaborative innovation, integrating diverse technical requirements into FPC solutions:

- Industry-Academia-Enterprise Co-R&D Platforms: Forward-looking suppliers establish joint R&D platforms with universities, research institutions, and downstream enterprises to tackle industry-specific technical bottlenecks. For example, in collaboration with medical device companies, they develop ultra-miniaturized, biocompatible FPCs for implantable devices; with new energy enterprises, they co-create high-temperature-resistant, high-current FPCs for energy storage systems. This collaborative model accelerates the iteration of FPC technologies and ensures solutions are closely aligned with market needs.

- Cross-Industry Technology Transplantation: Suppliers leverage technical insights from mature industries to innovate in emerging fields. For instance, they apply the high-precision circuit design technology used in aerospace FPCs to consumer electronics, improving the signal integrity of flexible displays; they transplant the corrosion-resistant material technology from industrial FPCs to marine energy storage equipment, enhancing environmental adaptability. This cross-industry technology migration enriches the solution portfolio and drives innovation across sectors.

- Early-Stage Embedded Collaboration: Top suppliers participate in clients’ product R&D phases at an early stage, providing professional FPC technical consulting. They work with clients to optimize product designs from the perspective of FPC integration, avoiding design conflicts and reducing subsequent modification costs. This embedded collaboration ensures that FPC solutions are seamlessly integrated into the overall product architecture, maximizing performance and reliability.

A professional Flexible PCB Supplier delivers customized solutions that cover multiple dimensions to meet the diverse needs of different industries:

- Application-Specific Material Customization: Materials are selected based on the operating environment and functional requirements of the application. For industrial control equipment operating in harsh environments, suppliers use ruggedized, chemical-resistant polyimide substrates; for wearable devices, they adopt ultra-thin, lightweight, and skin-friendly flexible materials; for high-frequency communication equipment, they choose low-dielectric-constant substrates to reduce signal loss. This material customization ensures FPCs adapt to various working conditions.

- Structural Design Optimization: Suppliers optimize FPC structures according to product form factors and assembly requirements. For complex products with irregular shapes, they design one-piece flexible circuits to reduce assembly links; for products requiring both flexibility and structural stability, they develop rigid-flex combined FPCs; for high-density integration scenarios, they adopt multi-layered circuit designs to improve space utilization. These structural optimizations enhance product integration efficiency and reliability.

- Functional Integration Tailoring: Based on industry-specific functional needs, suppliers integrate targeted functions into FPCs. For medical devices, they integrate EMI shielding functions to avoid interfering with sensitive diagnostic equipment; for automotive electronics, they add thermal management modules to cope with high-temperature environments; for smart home devices, they embed low-power consumption circuits to extend battery life. This functional customization enhances the added value of FPC solutions.

Aligning with global green development trends, leading Flexible PCB Suppliers integrate sustainability into their solution ecosystem:

- Eco-Friendly Material R&D & Application: Suppliers invest in the R&D and application of green materials, such as bio-based polyimides, recyclable copper foils, and water-based adhesives with low VOC emissions. These materials reduce the environmental impact of FPC production and use, while meeting the green product requirements of global clients.

- Energy-Saving Production Process Optimization: They optimize production processes to reduce energy consumption and waste generation. For example, adopting laser etching technology to improve material utilization, using closed-loop recycling systems to recover production scrap, and implementing intelligent energy management systems to reduce energy consumption. These measures promote the sustainable development of the entire industry chain.

- Long-Life Cycle Design: Suppliers design FPCs with long service lives and easy maintenance to reduce product replacement frequency. They use high-durability materials and optimized structural designs to extend FPC lifespan, and design modular structures to facilitate maintenance and replacement, reducing resource waste.

To support clients’ global market expansion, Flexible PCB Suppliers build comprehensive global service and compliance systems:

- Localized Service Networks: They establish localized service centers and production bases in key global markets, providing clients with timely technical support, order fulfillment, and after-sales service. This localized service model reduces logistics costs and lead times, enhancing client collaboration efficiency.

- Comprehensive Compliance Certification: Suppliers strictly comply with international standards and industry-specific regulations, such as IPC-6012/2221 for FPC quality, RoHS/REACH for environmental protection, IATF 16949 for automotive, and ISO 13485 for medical. They obtain relevant certifications to ensure FPC solutions meet the regulatory requirements of different countries and regions, facilitating clients’ global market access.

- Supply Chain Resilience Guarantee: They build a diversified and resilient global supply chain, establishing long-term cooperative relationships with multiple raw material suppliers. This ensures the stable supply of raw materials even in complex market environments, reducing supply chain risks for clients.

In conclusion, a Flexible PCB Supplier’s cross-industry collaborative innovation capabilities and customized solution ecosystem are key to supporting industrial innovation and development. By integrating industry-specific needs, promoting sustainable development, and providing global service support, these suppliers become indispensable strategic partners for clients across sectors. As industries continue to pursue digitalization and intelligence, the strategic value of partnering with a professional Flexible PCB Supplier will continue to rise, driving the continuous evolution of flexible electronic technology and industrial applications.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB