-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 19. 2025, 13:29:03

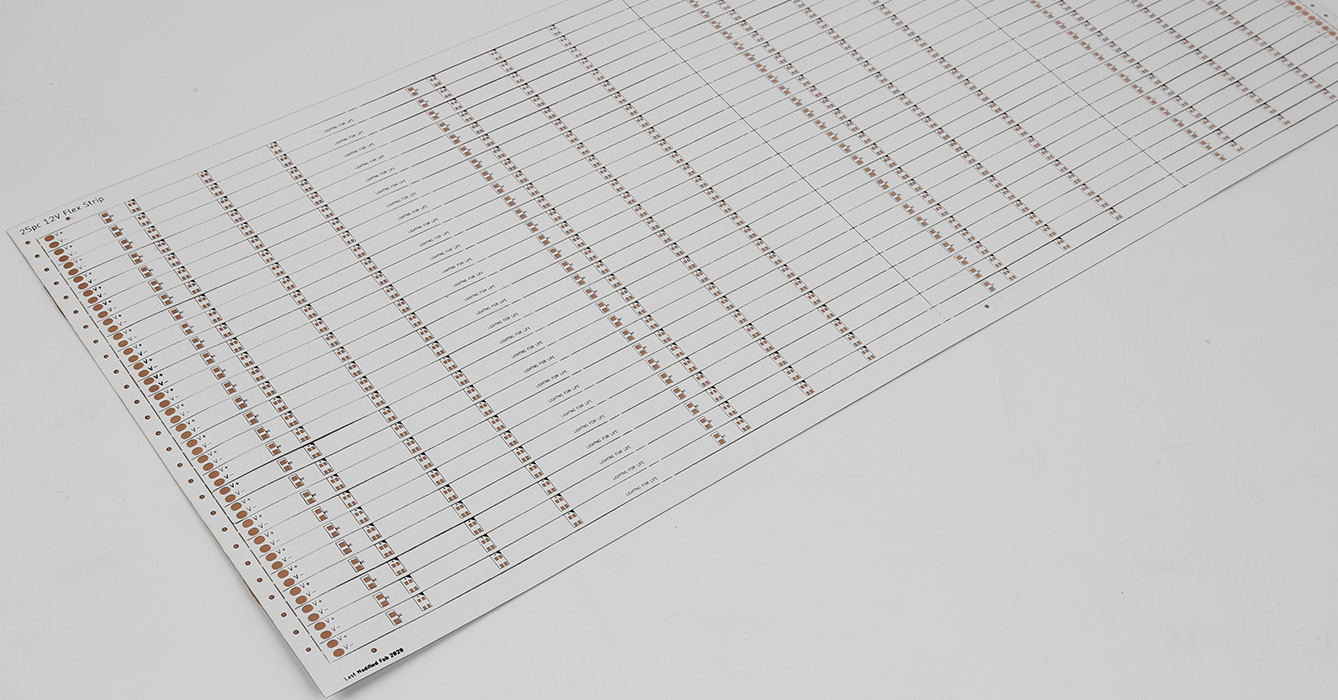

In the fast-evolving landscape of electronic technology, the demand for components that blend performance, adaptability, and compactness has reached new heights. Among these innovative components, flexible PCB (printed circuit board) stands out as a game-changer, redefining the possibilities of device design and functionality across countless industries. Unlike traditional rigid circuit boards, flexible PCB offers unique bendability, lightweight properties, and space-saving advantages, making it an indispensable choice for cutting-edge electronic products. As consumers and industries alike pursue smarter, smaller, and more durable devices, the role of flexible PCB in powering modern electronics continues to grow in significance.

Flexible PCB is constructed using flexible base materials, such as polyimide or polyester, which enable it to bend, fold, or conform to irregular shapes without compromising electrical performance. This fundamental difference from rigid PCBs addresses a key challenge in modern device design: the need to fit complex electronic components into tight or unconventional spaces. Unlike rigid boards that require fixed mounting and leave unused gaps, flexible PCB can be tailored to the exact contours of a device, maximizing space utilization and reducing overall product size. Additionally, the flexible nature of these boards enhances durability by absorbing vibrations and shocks, making them ideal for applications in dynamic environments. Whether in a foldable smartphone, a wearable fitness tracker, or an industrial sensor, flexible PCB overcomes the limitations of rigid alternatives, unlocking new design freedoms for engineers and innovators.

The versatility of flexible PCB has made it a cornerstone component in a wide range of industries, each leveraging its unique properties to enhance product performance. In the consumer electronics sector, flexible PCB is the driving force behind the sleek, foldable designs of modern smartphones and tablets. It also enables the miniaturization of wireless earbuds, smartwatches, and portable gaming devices, where space is at a premium. The automotive industry relies heavily on flexible PCB for advanced driver-assistance systems (ADAS), infotainment setups, and electric vehicle (EV) components. In these applications, the board’s ability to withstand high temperatures and vibrations ensures reliable performance in the harsh conditions of a vehicle’s interior and engine bay.

In healthcare, flexible PCB plays a critical role in life-saving and wellness devices. Wearable health monitors, such as heart rate trackers and glucose sensors, use flexible PCB to conform to the human body, ensuring comfort and accurate data collection. Implantable medical devices, such as pacemakers, also benefit from the board’s miniaturization and biocompatibility. Even in industrial and aerospace sectors, flexible PCB is used in sensors, control systems, and satellite components, where it must endure extreme environmental conditions while maintaining electrical integrity. Across all these industries, flexible PCB proves its adaptability, becoming a universal solution for complex electronic needs.

For engineers and product designers, the decision to integrate flexible PCB into a design is driven by a host of compelling benefits beyond flexibility alone. First and foremost, space efficiency is a major advantage. By conforming to the device’s shape, flexible PCB reduces the overall footprint of electronic components, enabling smaller, more portable products that align with consumer preferences. Secondly, the lightweight nature of flexible PCB contributes to energy efficiency, particularly in battery-powered devices like wearables and mobile gadgets. Less weight means less power consumption, extending battery life and improving user experience.

Reliability is another key benefit of flexible PCB. The absence of connectors (often required when using multiple rigid boards) reduces the risk of connection failures, a common issue in complex electronic systems. This not only improves product durability but also lowers maintenance costs and enhances user trust. Additionally, flexible PCB simplifies the manufacturing process by reducing the number of components and assembly steps, leading to greater production efficiency and cost savings. For businesses looking to innovate and stay competitive, these advantages make flexible PCB a strategic choice for product development.

As technology continues to advance, the role of flexible PCB is set to expand even further, driven by emerging trends in electronics. The rise of the Internet of Things (IoT) is creating a growing demand for compact, low-power sensors and connected devices, all of which rely on flexible PCB for miniaturization and reliability. The development of wearable technology and augmented reality (AR) devices is pushing the boundaries of flexible PCB design, requiring thinner, more flexible boards that can integrate with soft materials.

Sustainability is another trend shaping the future of flexible PCB. Manufacturers are increasingly adopting eco-friendly materials and production processes to reduce the environmental impact of electronic components. This includes the use of recyclable base materials and lead-free soldering techniques, aligning flexible PCB with global efforts to create more sustainable electronics. Additionally, advancements in flexible PCB technology, such as the integration of flexible displays and energy-harvesting components, are opening up new possibilities for innovative products that are both functional and environmentally friendly.

In conclusion, flexible PCB has established itself as a vital component in modern electronics, offering unparalleled versatility, space efficiency, and reliability. Its ability to adapt to diverse industry needs—from consumer gadgets to life-saving medical devices—makes it a cornerstone of innovation. As emerging technologies like IoT and wearable tech continue to evolve, the demand for flexible PCB will only grow, solidifying its position as the backbone of the next generation of electronic products. For businesses and designers looking to create innovative, high-performance devices, embracing flexible PCB is not just a choice but a necessity in today’s competitive electronic landscape.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB