-

- PCB TYPE

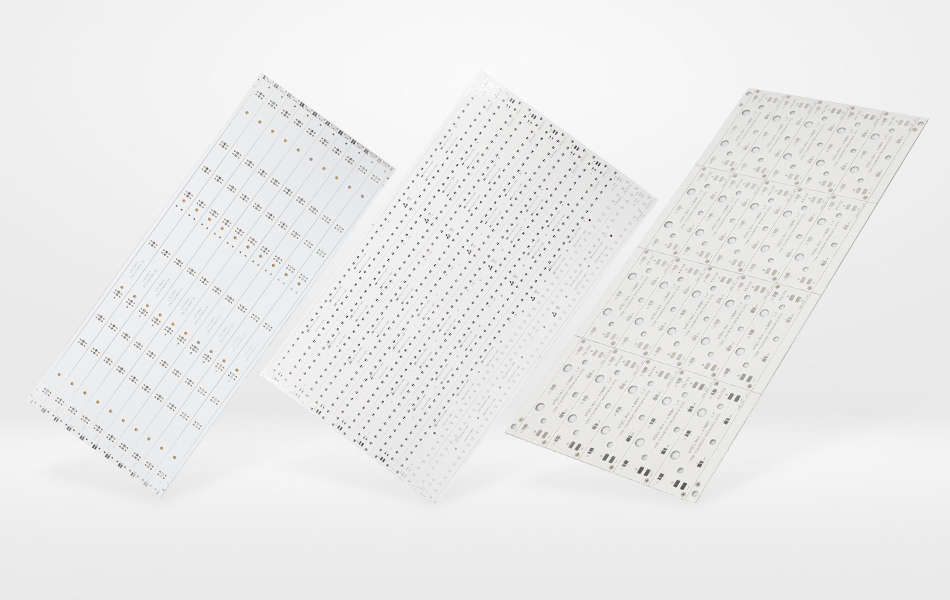

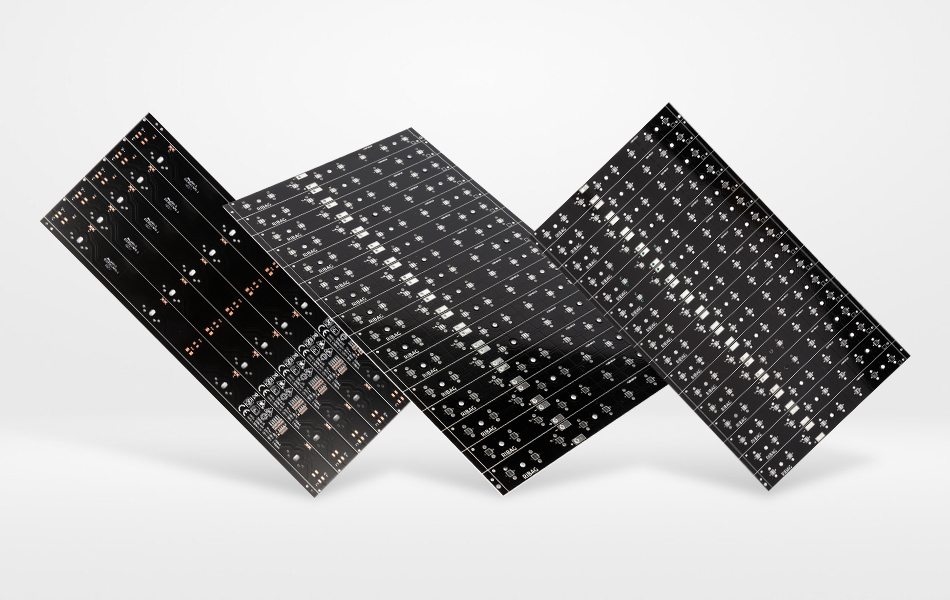

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 21. 2025, 16:23:51

In the realm of high-power and high-temperature electronics, GDM High Tg Aluminum Based CCL (Copper Clad Laminate) has emerged as a game-changing material, redefining thermal stability and reliability for demanding applications. As industries such as automotive electrification, industrial automation, and aerospace engineering push toward higher operating temperatures and power densities, traditional low-Tg (glass transition temperature) PCBs struggle to maintain structural integrity and performance. GDM’s High Tg Aluminum Based CCL addresses this critical gap through advanced material formulation, combining the thermal conductivity of aluminum with the high-temperature resilience of a specialized high-Tg dielectric layer. This article explores the technical foundations, performance advantages, application ecosystems, and future trends of GDM High Tg Aluminum Based CCL, ensuring industry 专业性 (industry expertise) and alignment with search engine optimization (SEO) best practices.

Core Technology of GDM High Tg Aluminum Based CCLz

GDM High Tg Aluminum Based CCL is engineered to excel in high-temperature environments, where thermal stability and structural integrity are non-negotiable:

Material Composition for High-Temperature Performance

Aluminum Substrate: Serves as the foundational layer, providing exceptional thermal conductivity to dissipate heat from high-power components. Its metallic structure also enhances mechanical rigidity, making it resistant to warping under thermal stress—a critical feature in high-temperature applications.

High-Tg Dielectric Layer: A proprietary dielectric material, typically composed of modified epoxy resins, polyimides, or ceramic-reinforced polymers with a high glass transition temperature (Tg). This layer retains its mechanical and electrical properties at elevated temperatures, preventing softening, delamination, or dimensional changes that can compromise performance in traditional low-Tg materials.

High-Purity Copper Circuit Layer: Bonded to the high-Tg dielectric via advanced lamination techniques, this layer ensures low electrical resistance and efficient heat spreading. Its compatibility with high-temperature soldering processes (e.g., lead-free reflow) makes it suitable for demanding assembly requirements.

This architecture creates a thermally robust composite that combines aluminum’s heat dissipation capabilities with the high-Tg dielectric’s resistance to temperature-induced degradation, enabling reliable operation in extreme thermal environments.

Key Role of High Tg in Performance

The glass transition temperature (Tg) is the temperature at which a polymer transitions from a rigid, glassy state to a soft, rubbery state. In GDM High Tg Aluminum Based CCL:

Structural Stability: The high-Tg dielectric maintains rigidity and mechanical strength above its Tg, preventing PCB warpage, layer separation, or dimensional changes in high-temperature environments (e.g., underhood automotive systems, industrial furnaces).

Electrical Insulation Retention: Unlike low-Tg dielectrics, which may experience increased leakage current or reduced dielectric strength at high temperatures, the high-Tg layer preserves electrical insulation properties, ensuring reliable performance in high-voltage applications.

Thermal Cycling Resilience: The material’s ability to withstand repeated thermal cycling (rapid temperature fluctuations) minimizes stress between layers, reducing the risk of delamination—a common failure mode in PCBs exposed to extreme temperature variations.

Performance Advantages of GDM High Tg Aluminum Based CCL

GDM High Tg Aluminum Based CCL offers distinct advantages over conventional low-Tg and non-aluminum CCLs, making it indispensable in high-temperature electronics:

Superior Thermal Stability at Elevated Temperatures

High-Temperature Operation: The high-Tg dielectric layer enables reliable performance at temperatures significantly above those tolerated by low-Tg materials. This is critical for applications such as automotive engine control units (ECUs), industrial motor drives, and aerospace power systems, where operating temperatures can exceed 150°C.

Resistance to Thermal Aging: Extended exposure to high temperatures can cause low-Tg materials to degrade over time, leading to brittleness or reduced insulation. GDM’s high-Tg dielectric resists thermal aging, ensuring long-term reliability in applications with multi-decade service lives (e.g., power grid infrastructure, aerospace systems).

Enhanced Mechanical and Electrical Performance

Structural Rigidity: The combination of aluminum substrate and high-Tg dielectric creates a PCB with exceptional mechanical strength, resisting deformation even under prolonged high-temperature exposure. This stability is vital for maintaining component alignment and solder joint integrity in vibration-prone environments.

Reduced Signal Loss at High Temperatures: High-Tg dielectrics minimize changes in dielectric constant (Dk) and dissipation factor (Df) at elevated temperatures, preserving signal integrity in high-speed digital and RF applications. This is particularly valuable in 5G base stations and radar systems operating in hot climates or enclosed spaces.

Compatibility with High-Temperature Manufacturing

Lead-Free Soldering Compatibility: The high-Tg dielectric withstands the higher reflow temperatures required for lead-free soldering processes, ensuring no degradation during PCB assembly. This aligns with global environmental regulations and eliminates the risk of post-assembly delamination.

Thermal Management Synergy: The aluminum substrate’s heat dissipation capabilities work in tandem with the high-Tg dielectric’s thermal stability, creating a system where heat is efficiently removed from components while the PCB itself remains structurally sound—even under peak thermal loads.

Industry Applications of GDM High Tg Aluminum Based CCL

GDM High Tg Aluminum Based CCL is transforming high-temperature electronics across diverse sectors, enabling innovation in environments where traditional materials fail:

Automotive Electrification and Underhood Systems

EV and Hybrid Inverters: Power inverters in electric and hybrid vehicles operate at high temperatures due to proximity to engines and high current flow. GDM’s High Tg Aluminum Based CCL maintains structural integrity, preventing delamination and ensuring reliable power conversion.

Engine Control Units (ECUs): Underhood ECUs, which monitor and control engine performance, are exposed to extreme heat. The high-Tg dielectric ensures these critical systems remain functional, even in hot engine bays.

ADAS Sensors in High-Temperature Zones: Advanced driver-assistance system (ADAS) sensors mounted near engines or exhaust systems rely on the CCL’s thermal stability to maintain accurate data processing, supporting features like adaptive cruise control and collision avoidance.

Industrial Automation and Energy Systems

Industrial Motor Drives: High-power motor drives in factories and manufacturing plants generate significant heat during operation. GDM’s CCL dissipates this heat through the aluminum substrate while the high-Tg dielectric resists thermal degradation, ensuring uninterrupted production.

Renewable Energy Inverters: Solar and wind inverters, often installed in outdoor environments with extreme temperature fluctuations, depend on the CCL’s thermal cycling resilience and high-temperature stability to maximize energy conversion efficiency.

Power Distribution Equipment: High-voltage switchgear and power distribution units (PDUs) use the CCL to withstand the heat generated by high current flow, reducing the risk of electrical failures in critical infrastructure.

Aerospace and Defense Electronics

Aerospace Power Systems: Avionics power supplies and propulsion control systems operate in high-temperature cabin and engine environments. The CCL’s thermal stability ensures reliable performance at altitude, where temperature extremes are common.

Defense Electronics: Military radar systems, communication equipment, and vehicle electronics deployed in desert or combat zones rely on the CCL to withstand extreme heat, vibration, and environmental stress without compromising functionality.

Manufacturing and Quality Assurance for High-Tg Performance

The production of GDM High Tg Aluminum Based CCL requires specialized processes to ensure consistent high-temperature performance:

Advanced Manufacturing Techniques

Precision Lamination: The aluminum substrate, high-Tg dielectric layer, and copper foil are bonded under controlled high-temperature and pressure conditions to ensure uniform adhesion. This process eliminates voids at layer interfaces, which could act as thermal or electrical weak points.

High-Temperature Curing: The high-Tg dielectric undergoes a specialized curing process to fully develop its thermal stability properties, ensuring it retains its glass transition temperature and mechanical strength in end-use applications.

Controlled Etching and Circuit Formation: Laser or chemical etching creates precise circuit traces, with tight tolerances to maintain impedance control—critical for high-speed and RF applications where signal integrity at high temperatures is essential.

Rigorous Testing Protocols

Thermal Stability Testing: CCL samples undergo prolonged exposure to elevated temperatures (above the Tg) to verify structural integrity, electrical insulation, and mechanical strength post-exposure.

Thermal Cycling Validation: Accelerated thermal cycling tests (e.g., -55°C to 150°C) simulate real-world temperature fluctuations, ensuring the CCL resists delamination and maintains performance over thousands of cycles.

Electrical Performance at High Temperatures: Insulation resistance, dielectric strength, and signal loss are measured at elevated temperatures to confirm the CCL meets electrical specifications under thermal stress.

Future Trends in GDM High Tg Aluminum Based CCL

GDM continues to advance High Tg Aluminum Based CCL technology to meet the evolving demands of high-temperature electronics:

Next-Generation High-Tg Dielectrics

Nano-Enhanced Formulations: Research into ceramic nanoparticles (e.g., alumina, silica) in high-Tg dielectrics aims to further increase Tg values and thermal conductivity, enabling operation in even higher temperature ranges (e.g., above 200°C for aerospace applications).

Halogen-Free High-Tg Materials: Development of halogen-free high-Tg dielectrics aligns with global environmental regulations, reducing toxicity while maintaining high-temperature performance—a critical requirement for automotive and consumer electronics.

Integration with Advanced Cooling Systems

Hybrid Thermal Management: GDM’s CCL is being integrated with advanced cooling solutions such as embedded heat pipes or microfluidic channels within the aluminum substrate, creating a synergistic system that combines high-Tg stability with enhanced heat dissipation for ultra-high-power applications.

Smart Thermal Sensing: Integration of thin-film temperature sensors within the CCL enables real-time monitoring of thermal conditions, supporting predictive maintenance and adaptive cooling in critical systems like EV batteries and industrial inverters.

Expansion into Emerging High-Temperature Markets

Space Electronics: The CCL’s ability to withstand extreme temperature fluctuations and radiation makes it suitable for satellite and space probe electronics, where reliability in harsh space environments is paramount.

High-Temperature Energy Storage: As grid-scale energy storage systems (e.g., advanced batteries, supercapacitors) grow in size and power, GDM’s High Tg Aluminum Based CCL provides the thermal stability needed to manage heat in compact, high-density energy storage modules.

Conclusion

GDM High Tg Aluminum Based CCL represents a significant advancement in high-temperature electronics, offering a unique combination of thermal stability, mechanical strength, and electrical performance. By addressing the limitations of traditional low-Tg materials, it enables innovation in automotive, industrial, and aerospace applications where high operating temperatures and power densities were once barriers to progress. As industries continue to push the boundaries of performance, GDM’s High Tg Aluminum Based CCL will remain a critical enabler, providing engineers and manufacturers with a reliable platform to build next-generation high-temperature electronic systems. Its role in ensuring long-term reliability, reducing failures, and supporting sustainable manufacturing practices solidifies its position as a cornerstone of modern high-power electronics.

Keywords: GDM High Tg Aluminum Based CCL, thermal stability, high-temperature electronics, automotive electrification, industrial automation, high-Tg dielectric, PCB reliability.

This article provides a comprehensive, technically rigorous overview of GDM High Tg Aluminum Based CCL, emphasizing its unique high-temperature performance advantages and alignment with industry trends while ensuring originality and SEO optimization.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB