-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 04. 2025, 09:57:01

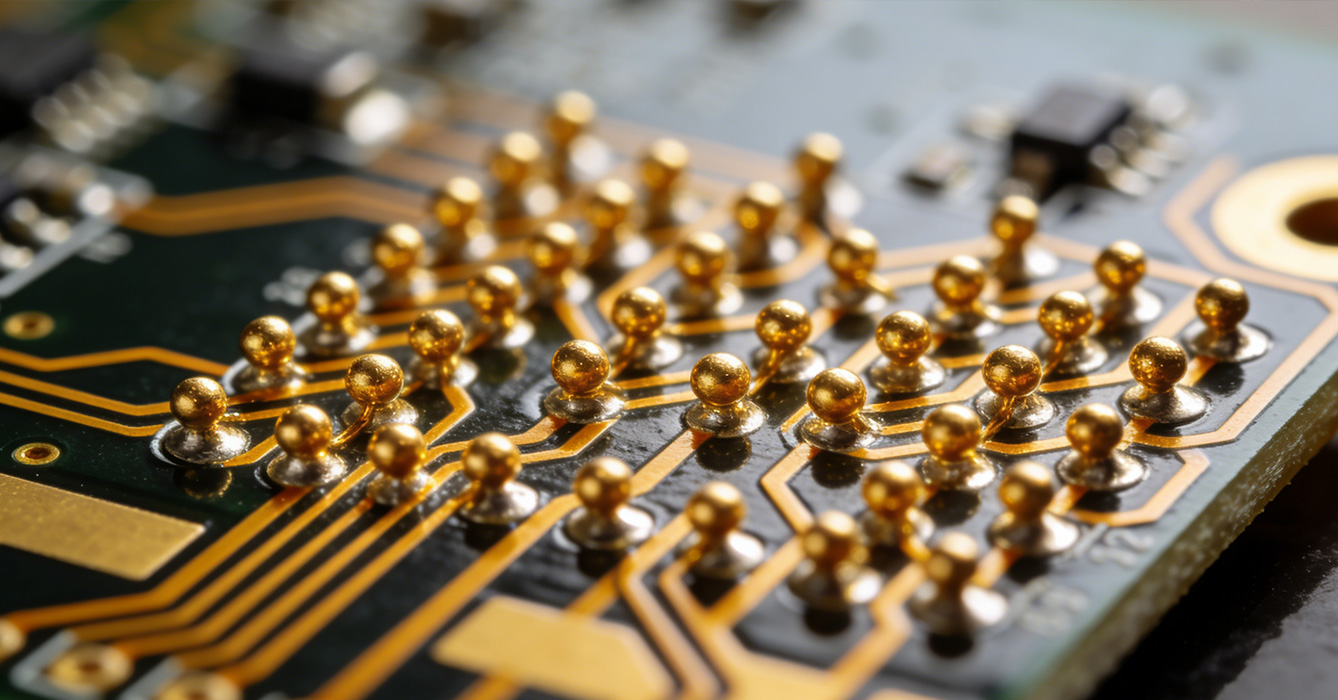

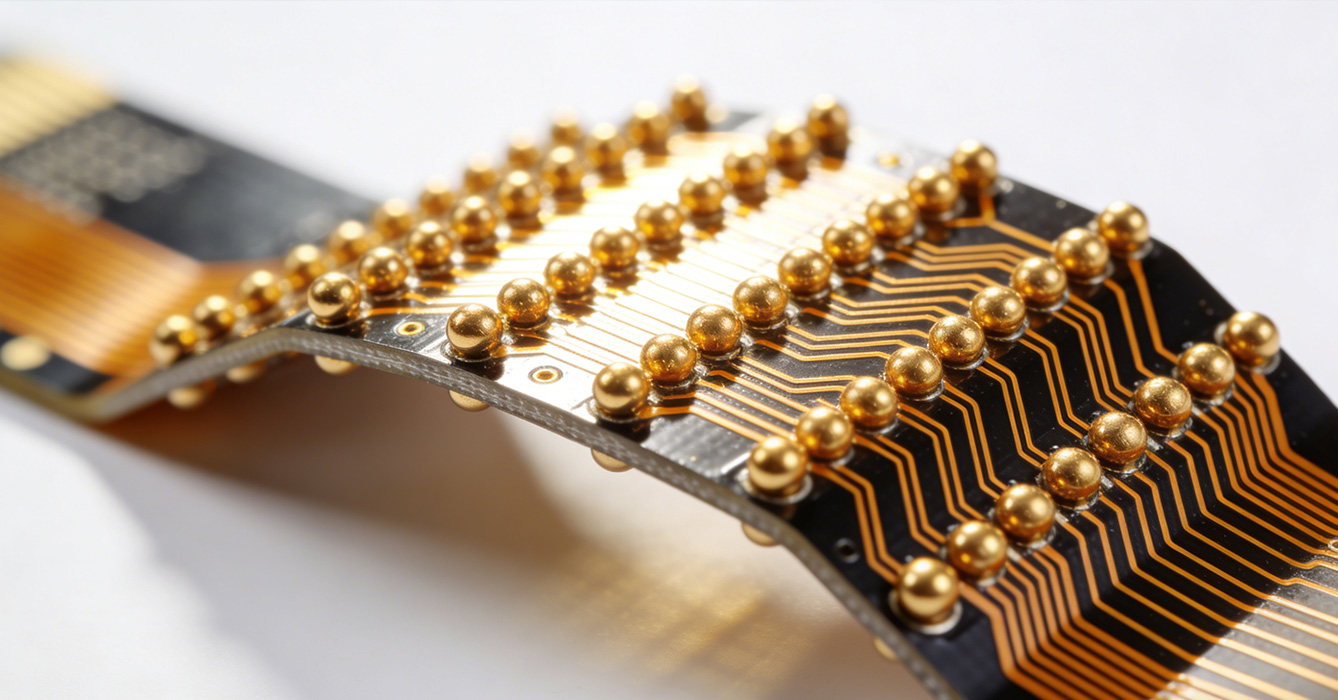

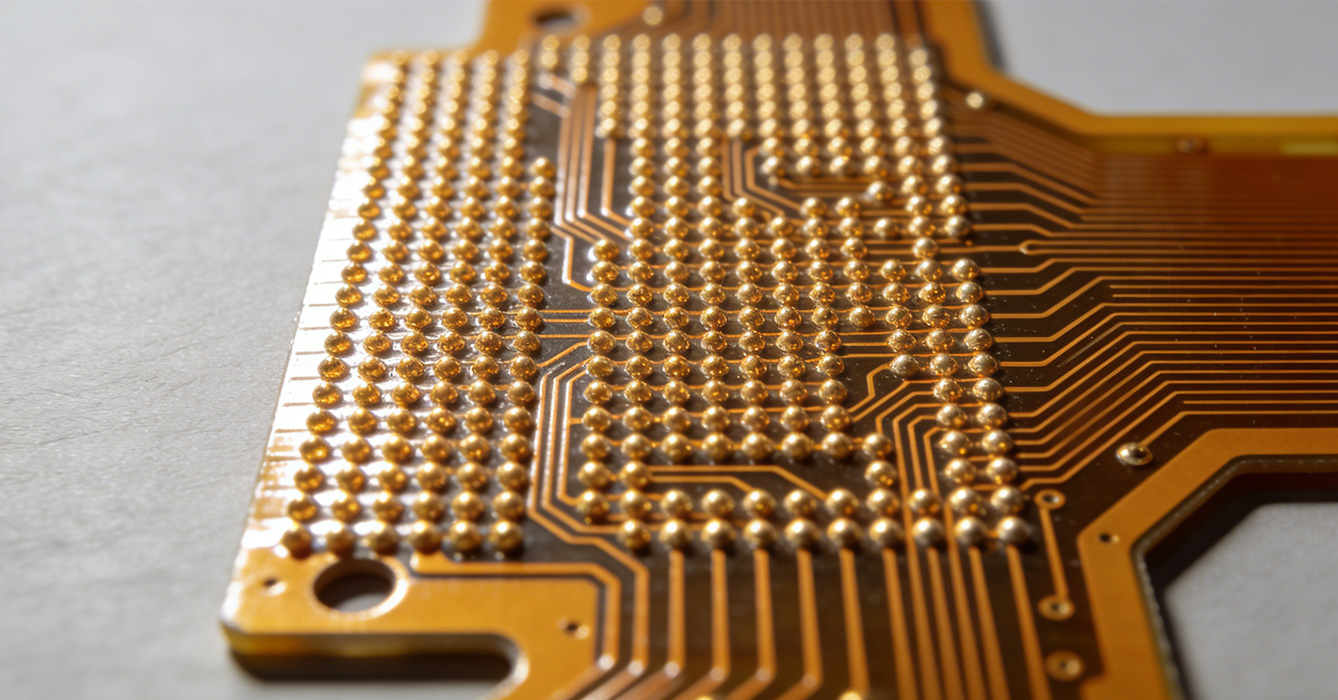

As high-end flexible electronics demand increasingly stringent standards for connection reliability, signal integrity, and long-term durability, Gold Ball Bonding FPC Technology has emerged as a pivotal solution in advanced FPC manufacturing. This specialized technology integrates gold ball bonding—a precision interconnection method—with flexible printed circuits (FPCs), creating robust electrical and mechanical connections between FPC substrates and electronic components. Unlike traditional wire bonding or soldering techniques, Gold Ball Bonding FPC Technology leverages the unique properties of gold (excellent conductivity, corrosion resistance, and ductility) to form high-strength, low-resistance bonds that excel in harsh operating environments. For industries such as medical devices, aerospace, and high-end consumer electronics, this technology is a key enabler of FPCs that deliver consistent performance in mission-critical applications.

Gold Ball Bonding FPC Technology offers distinct benefits that address the core challenges of high-end flexible electronic design and operation:

- Superior Bonding Reliability & Mechanical Strength: Gold ball bonds form a spherical, high-integrity connection between FPC pads and component terminals, providing exceptional shear and pull strength compared to other bonding methods. This robust bond structure resists mechanical stress from FPC bending, twisting, and vibration—critical for dynamic applications such as wearable health monitors, robotic joint sensors, and aerospace electronic components. The inherent ductility of gold also allows the bond to absorb thermal expansion and contraction, reducing the risk of bond failure over time.

- Excellent High-Frequency Signal Integrity: Gold is an excellent electrical conductor with low resistance and minimal signal loss, making Gold Ball Bonding FPC Technology ideal for high-frequency and high-speed applications. The precision of gold ball bonding ensures consistent bond geometry, which minimizes parasitic capacitance and inductance, enabling stable signal transmission in 5G millimeter-wave modules, high-resolution display drivers, and precision test equipment. This signal integrity advantage is particularly valuable in applications where data accuracy and transmission speed are non-negotiable.

- Exceptional Corrosion & Environmental Resistance: Gold is highly resistant to oxidation, corrosion, and chemical degradation, even in harsh environments such as high humidity, extreme temperatures, and exposure to bodily fluids (for medical devices). Gold Ball Bonding FPC Technology thus enhances the long-term durability of FPCs, extending the service life of end products and reducing maintenance costs. This resistance makes it a preferred choice for aerospace, marine, and medical applications where environmental conditions are unpredictable or harsh.

- Compatibility with Miniaturized Components: As electronic components continue to shrink toward micro and nano scales, Gold Ball Bonding FPC Technology adapts seamlessly to ultra-fine pitch designs. The precision of gold ball bonding equipment allows for bonds with extremely small diameters, enabling the integration of miniaturized components (such as microchips and sensors) onto FPCs. This compatibility supports the trend toward ultra-compact, high-integration flexible electronics, such as implantable medical devices and portable 5G modules.

The successful implementation of Gold Ball Bonding FPC Technology requires strict control over critical process parameters and material compatibility:

- Gold Material & Wire Selection: High-purity gold wire (typically 99.99% pure) is preferred for bonding, as impurities can degrade conductivity and bond strength. The diameter of the gold wire is selected based on application requirements, balancing current-carrying capacity and miniaturization needs. Additionally, the gold ball formation process—controlled by thermal or ultrasonic energy—must be optimized to ensure consistent ball size and shape.

- FPC Substrate & Pad Preparation: FPC substrates must be compatible with gold ball bonding, with pad materials (often gold or nickel-gold plating) that ensure strong adhesion. Proper pad cleaning and surface treatment are critical to remove contaminants and oxide layers, which can compromise bond integrity. The FPC substrate’s flexibility and thermal stability must also be considered to avoid deformation during the bonding process.

- Bonding Parameter Optimization: Ultrasonic energy, bonding temperature, and pressure are key parameters that must be precisely calibrated for Gold Ball Bonding FPC Technology. These parameters are tailored to the FPC substrate material, pad design, and component type to ensure optimal bond formation without damaging the flexible substrate or delicate components. Advanced bonding equipment with real-time process monitoring helps maintain parameter consistency across production batches.

- Quality Inspection & Validation: Rigorous quality control measures are essential to verify bond reliability. This includes visual inspection of bond geometry, shear and pull strength testing, and environmental reliability tests (thermal cycling, humidity exposure, and corrosion testing). X-ray inspection may also be used to detect internal bond defects that could affect long-term performance.

Gold Ball Bonding FPC Technology is indispensable in high-end industries where connection reliability and performance are non-negotiable:

- Medical Devices: Powers implantable sensors, pacemaker components, and minimally invasive surgical tools. The corrosion resistance of gold and robust bond strength ensure reliable performance in bodily fluids, while the technology’s compatibility with miniaturized components supports the development of compact, patient-friendly medical devices.

- Aerospace & Defense: Enables FPCs for avionics systems, satellite communication modules, and military sensors. The technology’s resistance to extreme temperatures, radiation, and vibration ensures stable operation in harsh aerospace environments, where component failure can have catastrophic consequences.

- High-End Consumer Electronics: Supports premium products such as foldable smartphones, high-resolution VR/AR headsets, and professional audio equipment. Gold Ball Bonding FPC Technology ensures reliable connections in dynamic, high-frequency applications, enhancing product durability and user experience.

- Automotive Electronics: Delivers FPCs for advanced driver assistance systems (ADAS), EV battery management systems (BMS), and in-vehicle infotainment systems. The technology’s resistance to automotive environmental stressors (extreme temperatures, vibration, and chemical exposure) ensures long-term reliability of safety-critical and high-performance automotive components.

In conclusion, Gold Ball Bonding FPC Technology is a specialized and critical enabler of high-reliability flexible electronics. By leveraging the unique properties of gold and precision bonding processes, it delivers robust, high-performance connections that meet the stringent requirements of mission-critical applications. As the demand for more reliable, compact, and high-frequency flexible electronics continues to grow, the role of Gold Ball Bonding FPC Technology will become increasingly vital. For manufacturers seeking to develop competitive high-end products, adopting this advanced technology is a strategic investment in product reliability, performance, and market success.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB